35kv indoor transformer substation cleaning device with dust-proof function

A technology for cleaning devices and substations, which is applied to cleaning methods using tools, switchgear, and dust removal, etc. It can solve problems that affect the health of cleaning workers, cannot clean large-scale cleaning equipment, and limited indoor space in substations. Effects of cleaning floating dust, protecting health, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

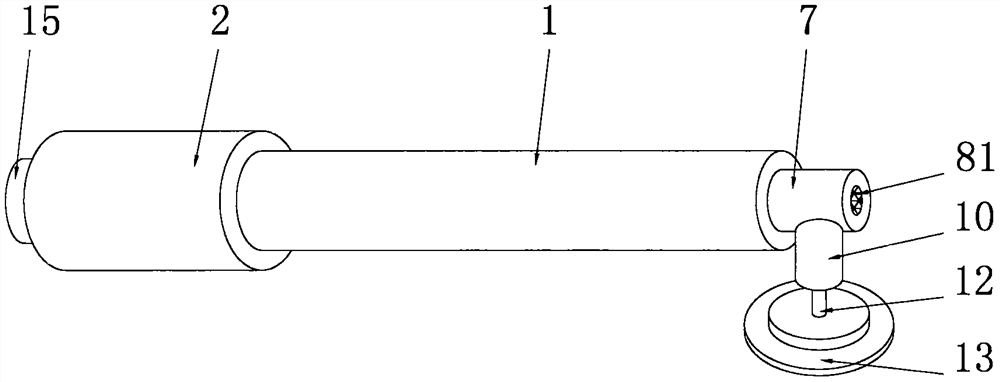

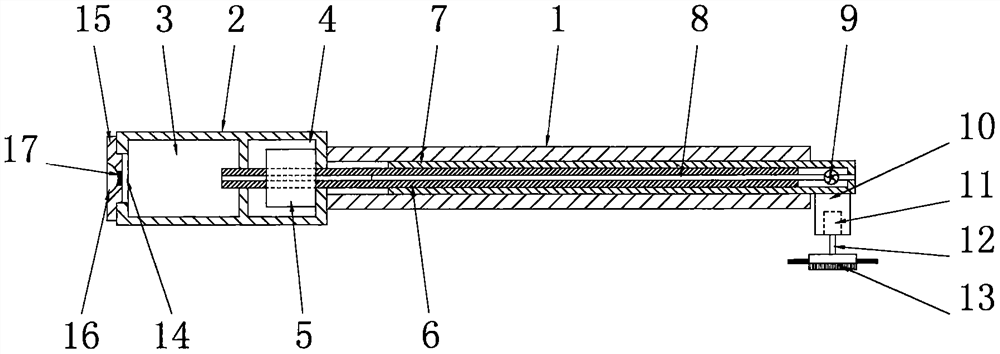

[0030] See Figure 1-2 , a 35kv indoor substation cleaning device with dustproof function, including a guide tube 1, the guide tube 1 is a round tube structure with open left and right ends, one end of the guide tube 1 is fixedly connected to the handle 2, and the guide tube 1 The axis coincides with the axis of the handle 2. The handle 2 is provided with a dust storage chamber 3 and an extension chamber 4. The extension chamber 4 is located on the right side of the dust storage chamber 3. The extension chamber 4 is provided with an extension motor 5. The guide tube 1 is provided with a screw 6, the axis of the screw 6 coincides with the axis of the guide tube 1, the screw 6 is a hollow tube structure, one end of the screw 6 extends through the motor 5 and connects the dust storage chamber 3, the screw 6 It is the rotor of the extension motor 5. The screw rod 6 is rotatably connected to the handle 2. The outer side of the screw rod 6 is provided with a shrinking tube 7 matched...

Embodiment 2

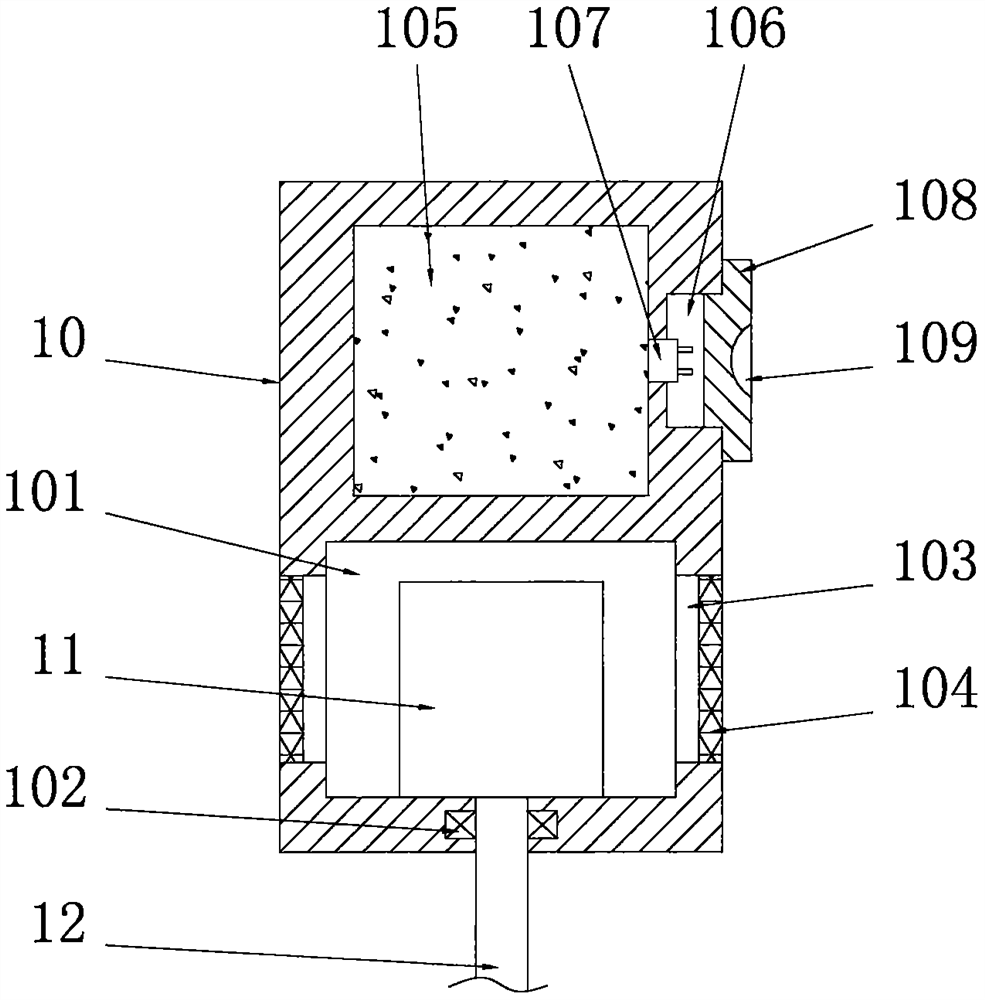

[0034] See image 3 The difference from Embodiment 1 is that the cleaning cylinder 10 is provided with a power chamber 101, the cleaning motor 11 is fixedly installed on the inner cavity bottom wall of the power chamber 101, and the rotating shaft 12 is connected to the cleaning chamber through a bearing 102 for rotation. On the cylinder 10, the side wall of the power chamber 101 is uniformly connected with a plurality of heat dissipation windows 103, and the second protective net 104 is installed in the heat dissipation window 103, and the heat dissipation of the cleaning motor 11 can be directly performed through the heat dissipation windows 103, which can effectively Guarantee the continuous operation of the cleaning motor 11;

[0035] The cleaning cylinder 10 is embedded with a storage battery 105, and the storage battery 105 is arranged above the power chamber 101. One side of the cleaning cylinder 10 is provided with a charging chamber 106, and the inner wall of the char...

Embodiment 3

[0037] See Figure 4-5 The difference from Embodiment 1 is that the cleaning assembly 13 includes a seat cover 1301, the seat cover 1301 is a disc-shaped structure, the bottom end of the rotating shaft 12 is fixedly connected to the top end of the seat cover 1301, and the axis of the rotating shaft 12 Coincident with the axis of the seat cover 1301, the bottom end of the seat cover 1301 is provided with an installation cavity 1302, the top wall of the inner cavity of the installation cavity 1302 is provided with a substrate 1303, and the edge of the seat cover 1301 is evenly provided with a number of pressing Rod 1307, the bottom end of the pressure rod 1307 runs through the base plate 1303 and is fixedly connected with a cleaning plate 1304 matched with the installation cavity 1302, the top end of the pressure rod 1307 is fixedly connected with the pressure plate 1308, and the pressure rod 1307 is respectively connected to the seat cover 1301 and the base plate 1303 Sliding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com