Wind power inspection robot

An inspection robot and wind power technology, which is applied in the monitoring of wind engines, machines/engines, and wind engines, etc., can solve the problems of poor battery life of inspection drones, inconvenient inspection of wind turbine blades, and general effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

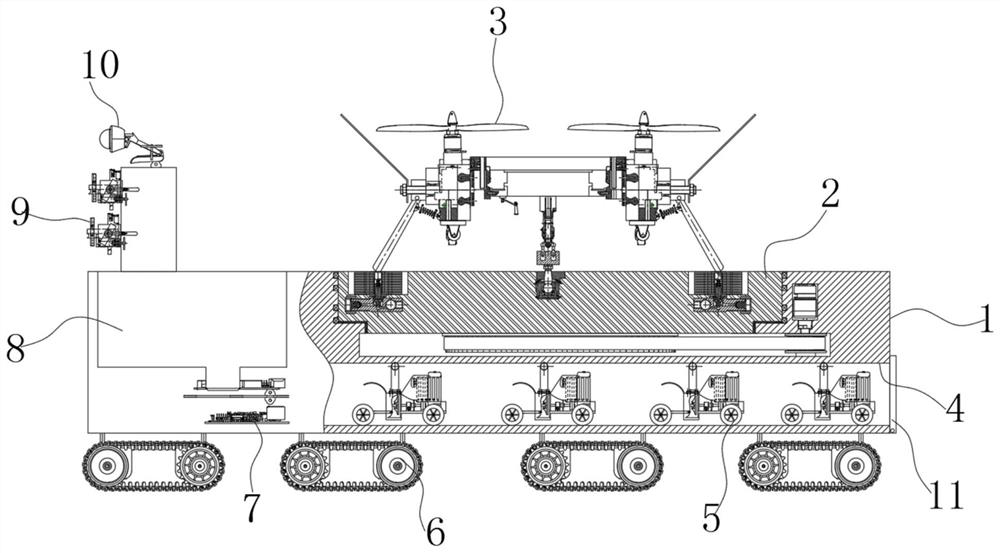

[0028] see Figure 1~4 , in an embodiment of the present invention, a wind power inspection robot, including

[0029] Inspection robot body 1,

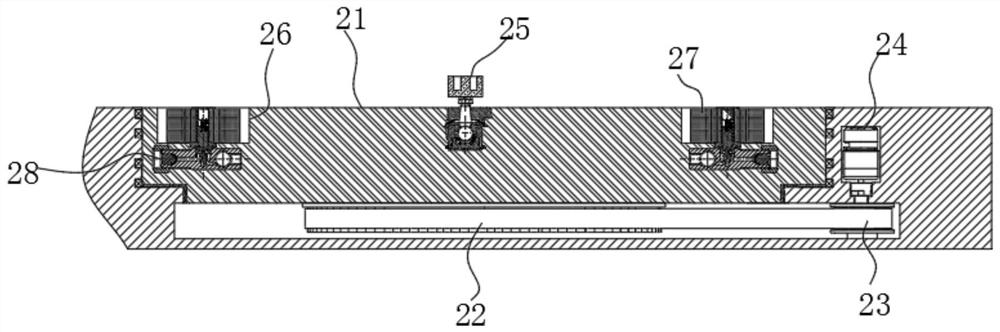

[0030] The alignment platform assembly 2 includes a rotating alignment platform 21 that can rotate along its central axis and is arranged on the inspection robot body 1,

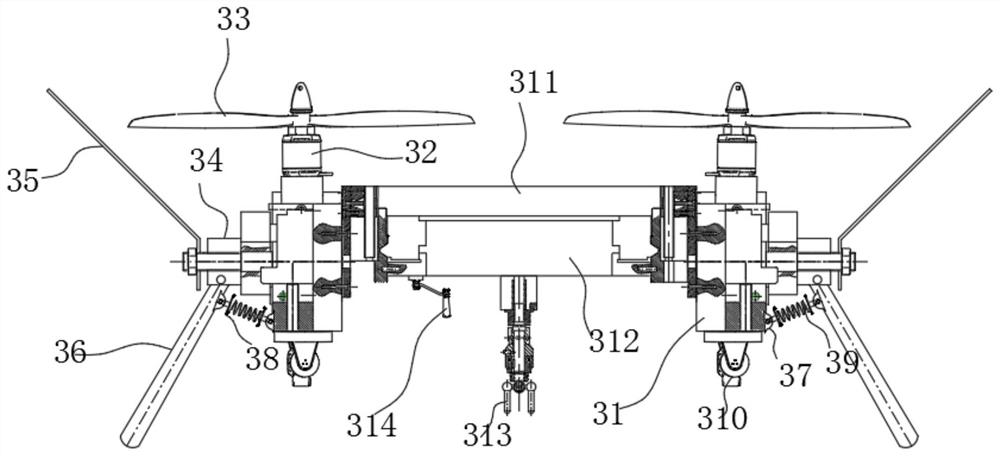

[0031] Inspection drone 3, which is placed on the rotating alignment platform 21; and

[0032] The inspection vehicle 5 is placed in the storage compartment 4 of the inspection robot body 1, and when the inspection robot body 1 arrives at the wind power detection position, the inspection drone 3 detects the wind power blades, and the inspection Car 5 detects the electrical equipment in the inner warehouse of the wind power installation column.

[0033] In this embodiment, the bottom of the inspection robot body 1 is provided with a plurality of walking crawlers 6, and the top of the inspection robot body 1 is provided with a laser sensor 9 and a probe 10 facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com