Online full-automatic screw powder filling machine with correction and inspection-free functions

A fully automatic, filling machine technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

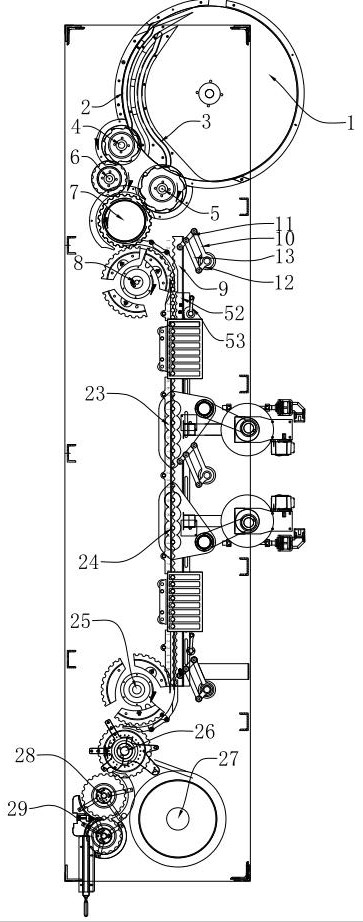

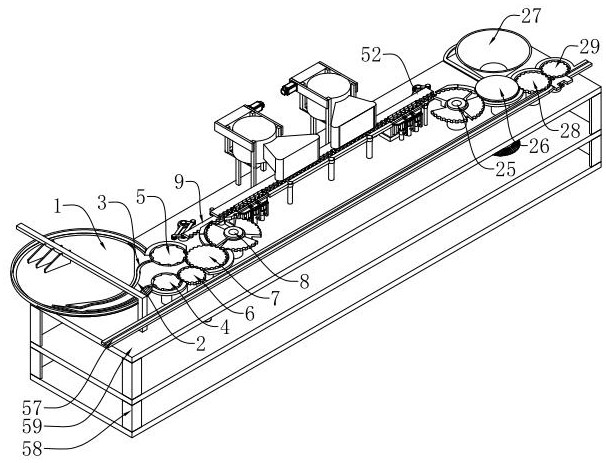

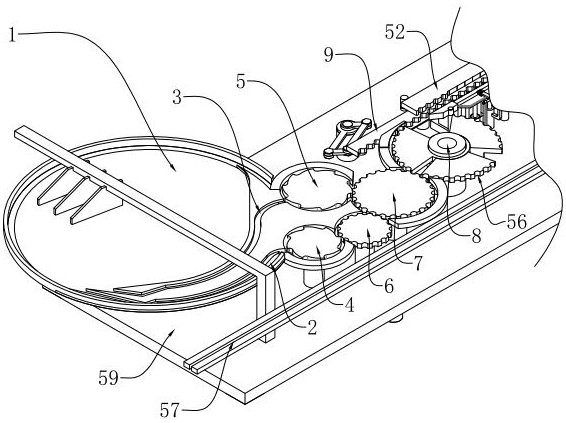

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0055] In this embodiment, each group of unequal-speed bottle-feeding components conveys 8 vials as an example for illustration. The structural principle of the device with a conveying quantity of 10 is consistent with that of this embodiment, and will not be repeated here.

[0056] refer to figure 1 with figure 2 , an on-line automatic screw powder filling machine with the function of correction and inspection-free, including a non-uniform-velocity bottle feeding component, a primary online weighing component, a front and rear filling component, and a secondary online weighing unit, which are successively arranged along the conveying direction of the vial Components, variable speed bottle output assembly, stoppering assembly, sampling and rejecting assembly, and also includes a power mechanism for driving each assembly, a transfer track 57 that is compati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com