Novel pack cutting device for round hay bales

A round straw bale and bale device technology, applied in the directions of packaging, transportation and packaging, cutting and unsealing, etc., can solve the problems of inability to remove films and thin nets, waste of hydraulic cylinder power resources, and poor cutting effect. High efficiency, labor saving, flexible and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

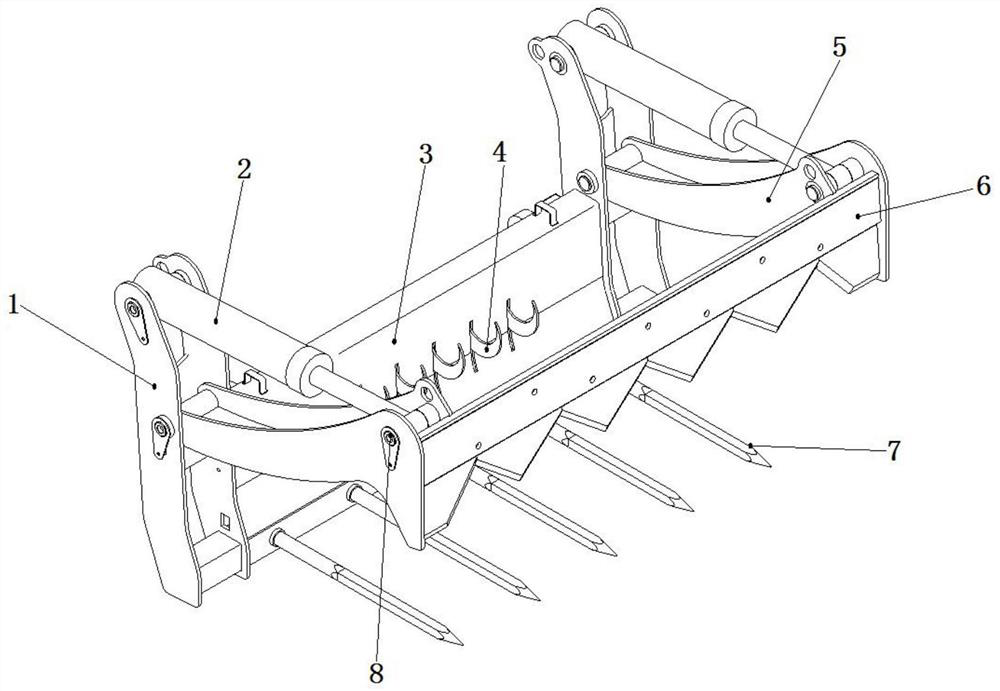

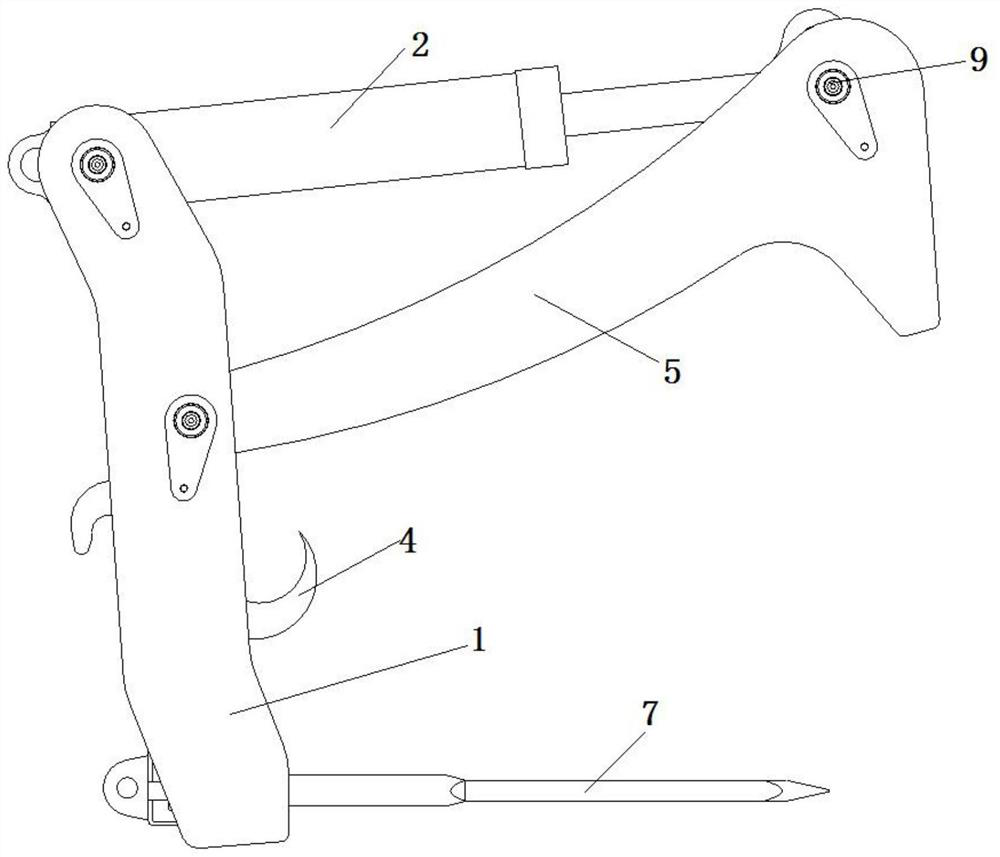

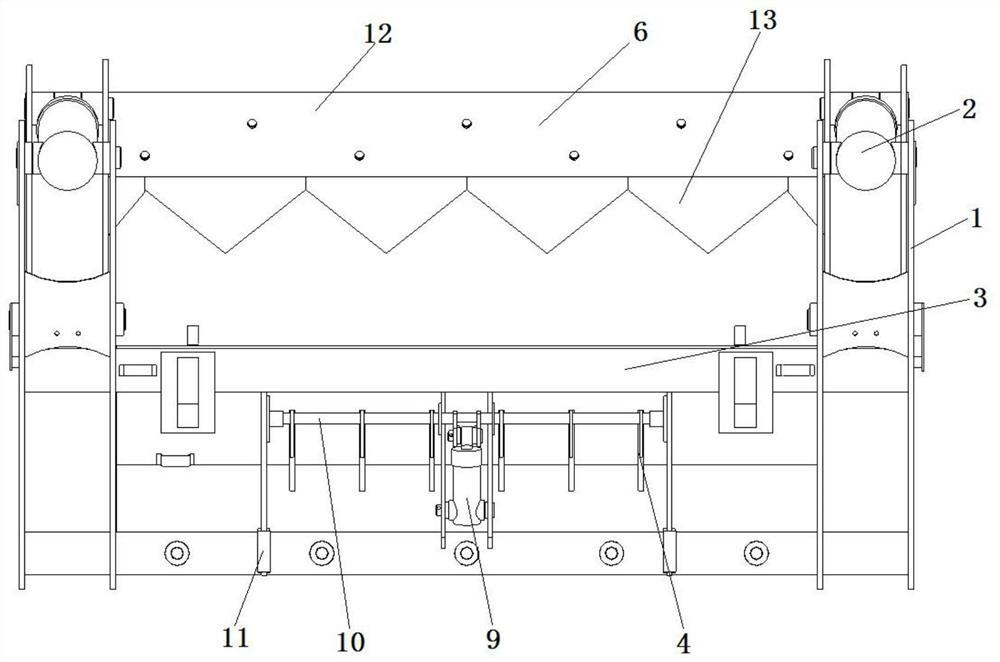

[0031] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a kind of round bale cutting device of this embodiment, comprise fixed frame 1, first hydraulic cylinder 2, fixed frame front baffle plate 3, bale cutting arm 5, cutter device 6 and fixed tooth 7 , one end of the first hydraulic cylinder 2 is connected with the fixed frame 1, the other end of the first hydraulic cylinder 2 is connected with the bale cutting arm 5, and the other end of the bale cutting arm 5 is connected with the fixed frame 1, and the round bale to be cut is placed on the fixed frame. On the tooth 7, the cutter device 6 is fixedly installed on the bag cutting arm 5, and the fixed tooth 7 is fixedly installed on the fixed frame 1, and the first hydraulic cylinder 2 is pushed forward to drive the bag cutting arm 5 and the cutter device 6 to move downward. The bale cutting arm 5 and the fixed teeth 7 fix the round bale, and the round bale is cut by the cutter device 6. T...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, a kind of round bale cutting device of this embodiment, one end of the first hydraulic cylinder 2 is connected to the fixed frame 1 in a hinged manner, the first hydraulic cylinder 2 is hinged on the fixed frame 1, The angle of the first hydraulic cylinder 2 can be adjusted at any time. If the cutter device 6 has been used for a long time and has a poor cutting effect or is stuck in a round bale, the angle of the first hydraulic cylinder 2 can be manually opened and replaced.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1-Figure 6 Describe this embodiment, a kind of bale cutting device of round bale of this embodiment, described bale cutting arm 5 is connected with the output end of first hydraulic cylinder 2 through pin shaft 8, and bale cutting arm 5 is installed on The output end of the first hydraulic cylinder 2 is convenient for the dismounting of the bale cutting arm 5, if the bale cutting arm 5 is used for a long time and is damaged, it can be disassembled at any time, reducing maintenance time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com