Integrated prefabricated lighting inspection well for automatic pollution discharge

A technology for automatic sewage and maintenance wells, which is applied in the direction of reaction engines, electric components, drainage structures, etc., can solve the problems of fragile maintenance wells and no impact resistance, and achieves the effect of green material, strong impact resistance, and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

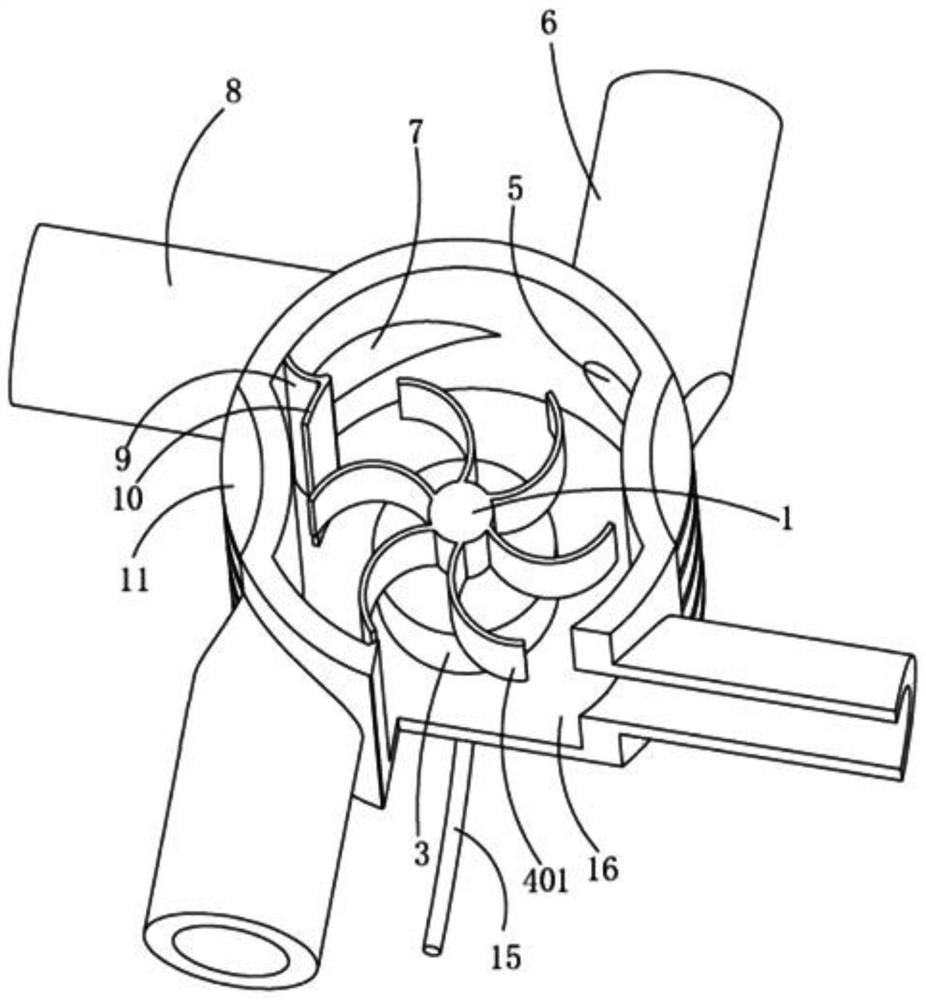

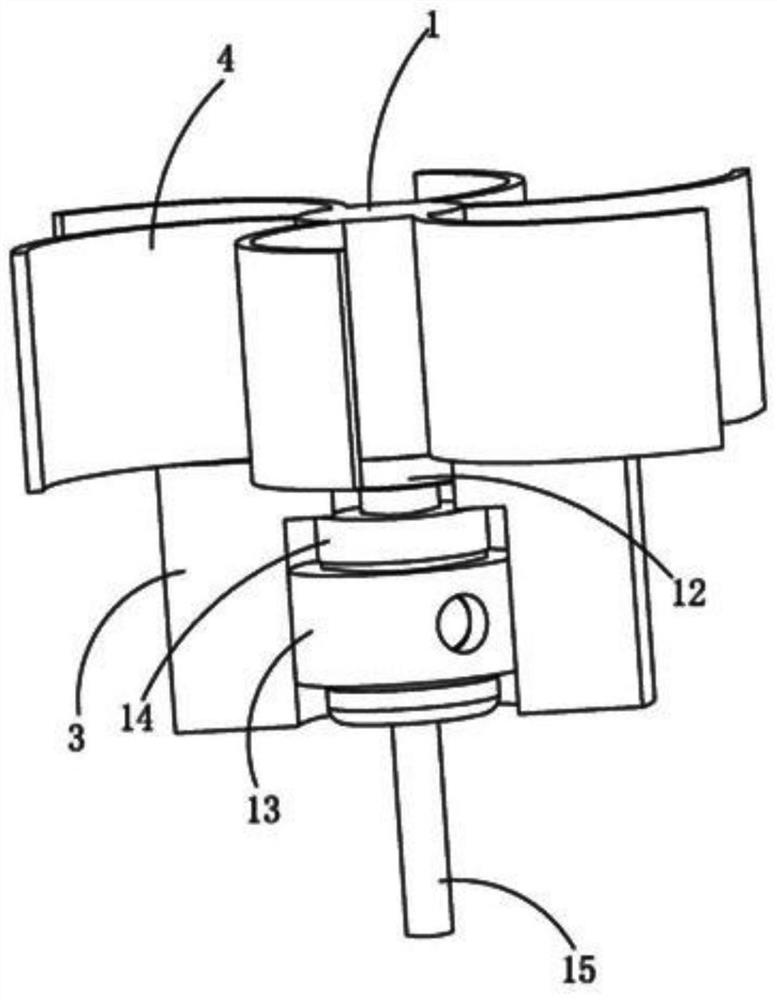

[0023] Such as Figure 1~2As shown, the integrated prefabricated lighting maintenance well for automatic sewage discharge of the present invention includes a maintenance well body 2, and the maintenance well body 2 is provided with a water outlet 7 and several inlets. A water outlet 5, the water outlet 7 is connected with a water outlet pipe 8, and the water inlet 5 is connected with a water inlet pipe 6; the maintenance well body 2 is also provided with an impeller base 3, and one end of the impeller base 3 is connected to There is an impeller 4, and the other end of the impeller base 3 is connected to an energy storage device (not shown in the figure), which is used to store the electric energy converted by the power of the impeller rotation. Place the maintenance well at the position set in advance. When water flows into the water inlet pipe 6, the water flow speed will slow down after entering the water outlet pipe 8. At this time, the impeller 4 will work to drive the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com