Extraction method for covering breathing plane domain of worker

An extraction method and technology for workers, which are applied in the field of air supply design of industrial sites, can solve the problems of non-existent protection effect of workers' breathing zone, lack of technical means, and enlarged space range, so as to achieve easy control and implementation, and improve the working environment. , The effect of saving air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

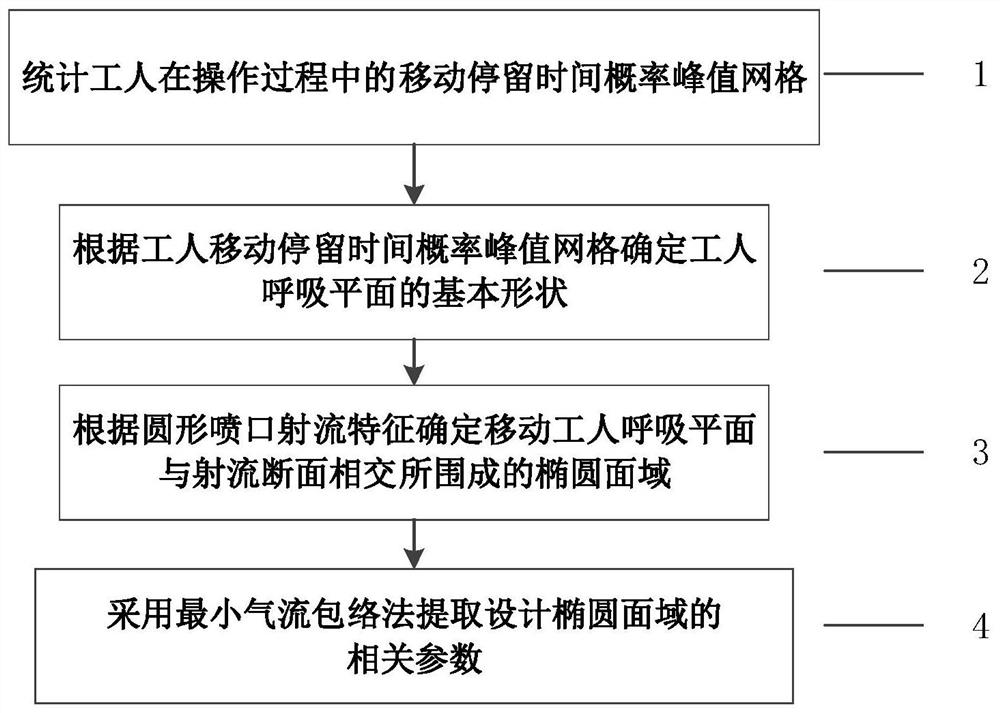

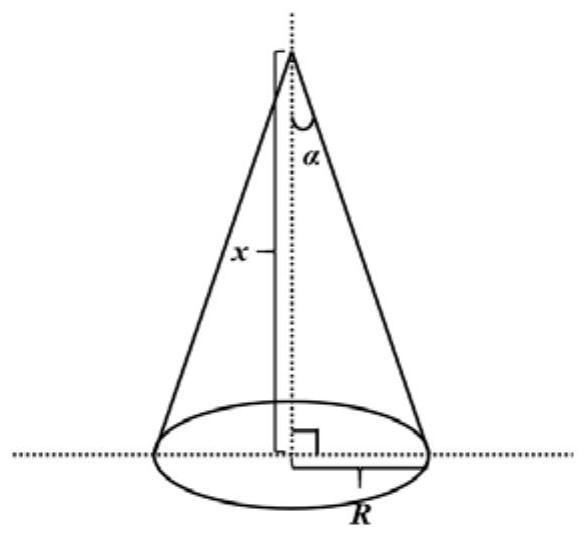

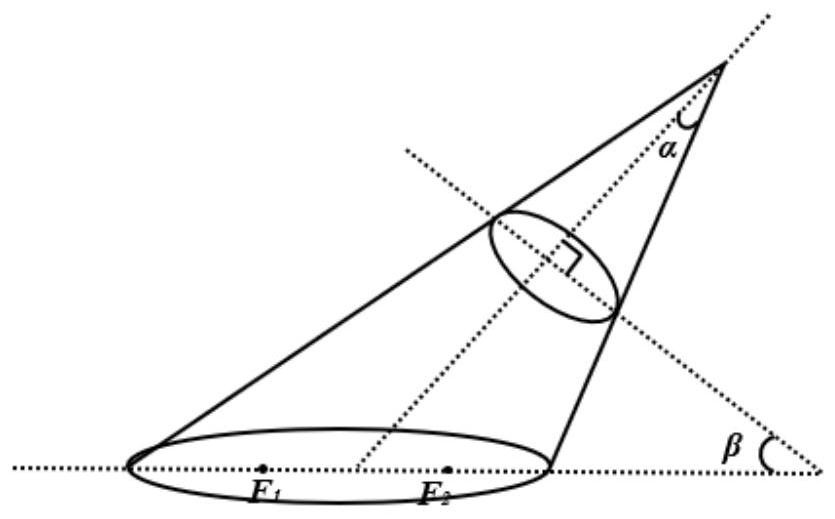

[0043] Such as figure 1Shown is the flow chart of the implementation of the method of the present invention. Preferably, the circular nozzle is selected as the air supply device for the worker's respiratory protection airflow. Then, according to the basic characteristics of the jet, the air supply from the nozzle will intersect the plane where the worker's breathing height is. When the plane is perpendicular to the jet axis, the intersecting section is circular, as shown in Figure 2(a); when the plane is non-orthogonal to the jet axis, the intersecting section is elliptical, as shown in Figure 2(b).

[0044] Such as image 3 As shown, related studies have shown that the movement trajectory of workers in industrial sites has significant statistical characteristics, that is, the probability of workers staying in a certain area can be determined by counti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com