Semiconductor package and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as tin bridge short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] According to some embodiments, the present invention provides a semiconductor package combining a fine-pitch interconnect structure and a coarse-pitch interconnect structure, the fine-pitch interconnect structure being embedded in a single dielectric layer and separated from the conductive contacts by an insulating layer. Therefore, tin bridge generation can be avoided. In addition, only a single dielectric layer can be used to increase the circuit density per unit volume without using a multi-layer structure, which will reduce the thickness and manufacturing cost of semiconductor packaging devices, and can avoid warpage due to increased thickness. Phenomenon.

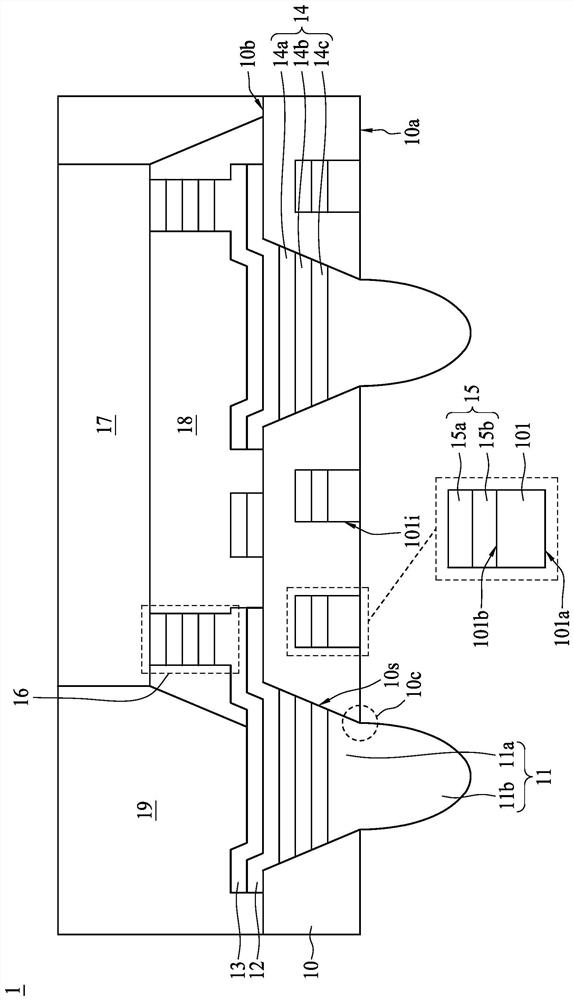

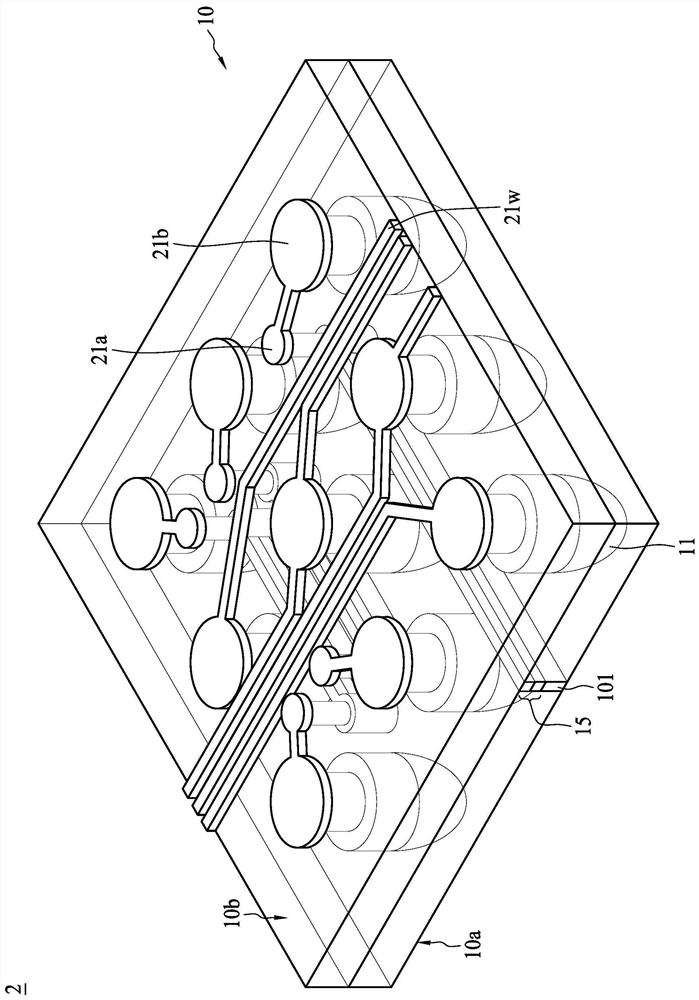

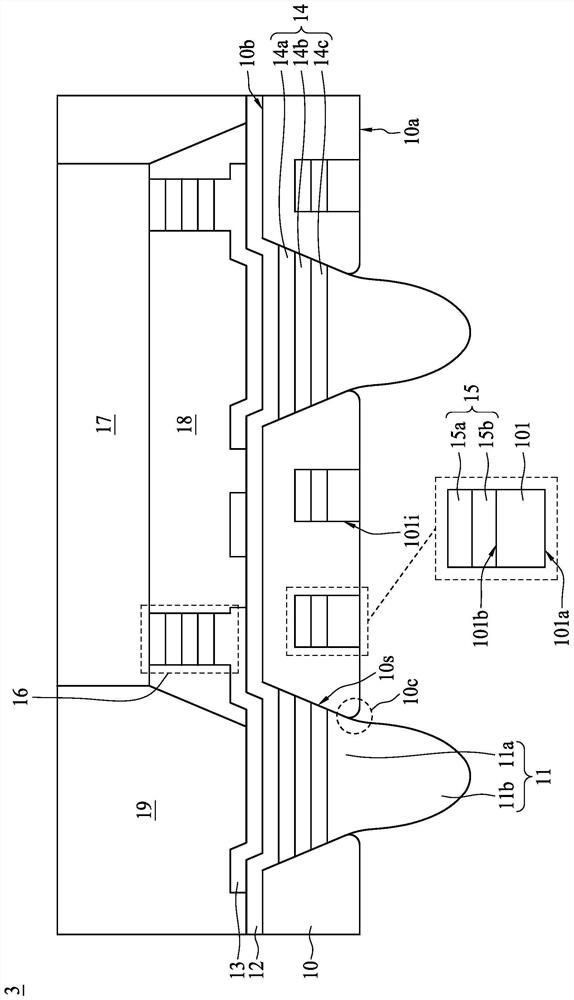

[0014] refer to figure 1 , figure 1 Shown is a cross-sectional view of a semiconductor package 1 according to some embodiments of the present disclosure. The semiconductor package 1 includes a substrate 10, a conductive contact 11, a seed layer 12, a metal layer 13, a conductive pillar 14, a metal layer 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com