PNP-type high-voltage ESD device based on BCD process, and LDMOS

An ESD device, high-voltage technology, applied in the field of LDMOS, PNP type high-voltage ESD devices, can solve the problems of high on-resistance, high secondary breakdown voltage, low secondary breakdown current, etc., to improve performance and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

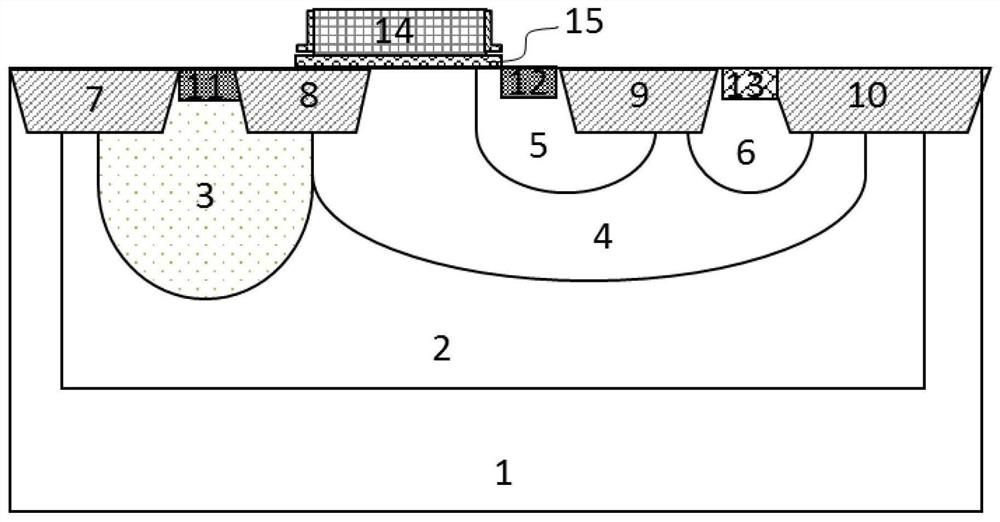

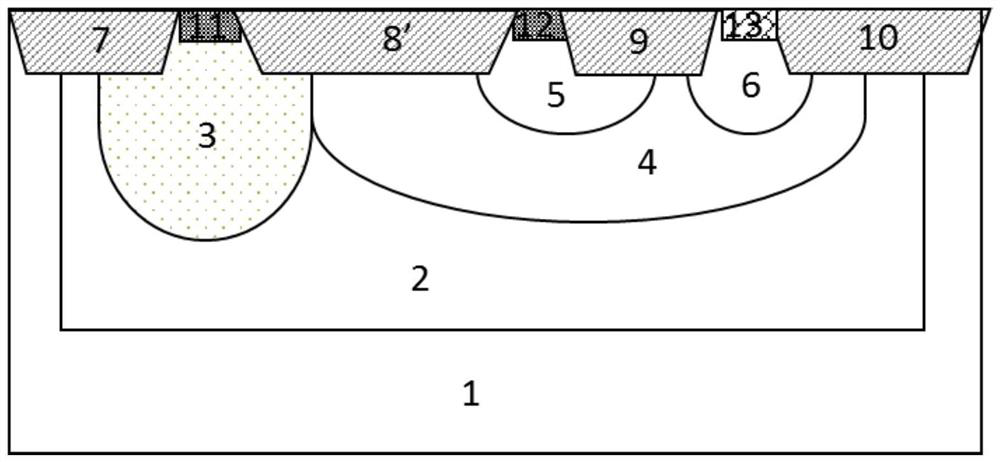

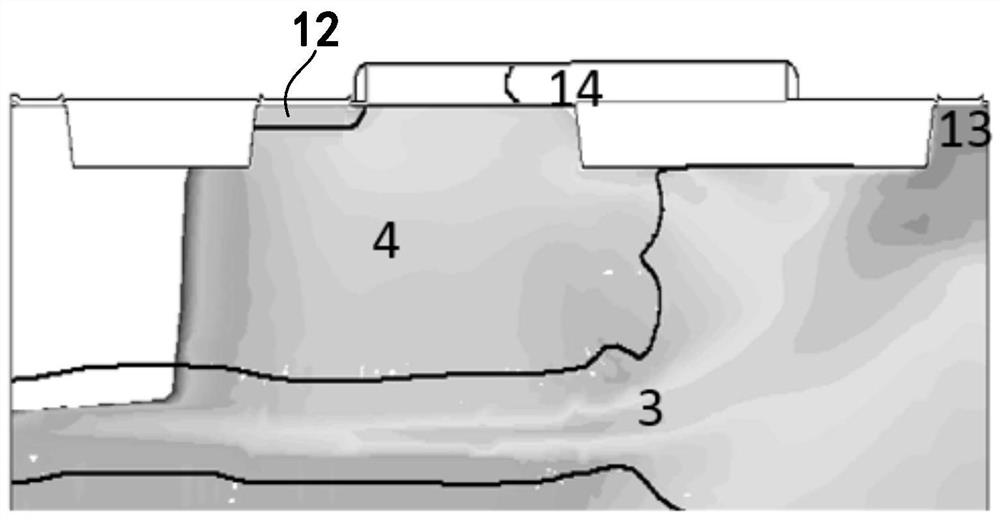

[0035] Such as figure 1 As shown, this embodiment discloses a PNP-type high-voltage ESD device based on BCD technology, including a P substrate 1, a high-voltage N well 2, a P-type drift region 3, an N-type drift region 4, a first N well 5, a first Two N-wells 6 , N-type base 13 , P-type collector 11 , P-type emitter 12 , polysilicon gate 14 , gate oxide layer 15 , first STI8 , second STI7 , third STI9 and fourth STI10 . Among them, the PNP high-voltage ESD device is a PNP transistor; the working voltage range is 40-65V; the node range of the BCD process is 65-180nm.

[0036] Wherein, the first STI 8 is located between the P-type collector 11 and the P-type emitter 12 . The polysilicon gate 14 is located in the upper region of the two ends adjacent to the first STI 8 and the P-type emitter 12 . The gate oxide layer 15 is located between the polysilicon gate 14 and the second STI 8 and the P-type emitter 12 . The high-voltage N well 2 is located in the P substrate 1; the P-t...

Embodiment 2

[0042] This embodiment discloses an LDMOS, which is a high-voltage LDMOS, including the BCD-based PNP high-voltage ESD device disclosed in Embodiment 1. Among them, the PNP high-voltage ESD device based on the BCD process is used to realize the ESD protection of the high-voltage LDMOS. When the peak voltage caused by the instantaneous current exceeds its 40-65V working voltage but does not reach the secondary breakdown voltage, the LDMOS guides the current through the PNP high-voltage ESD device to achieve ESD protection. In this embodiment, by adjusting the structure of the PNP-type high-voltage ESD device, a higher secondary breakdown current It2, a lower on-resistance Ron and a lower The secondary breakdown voltage Vt2. The volume of the device can be reduced, and the performance of the device can be greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com