High-power permanent magnet direct-drive freight locomotive modular traction converter

A technology of traction converter and permanent magnet direct drive, which is applied in the direction of converting AC power input to AC power output, locomotives, motor vehicles, etc. Types and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

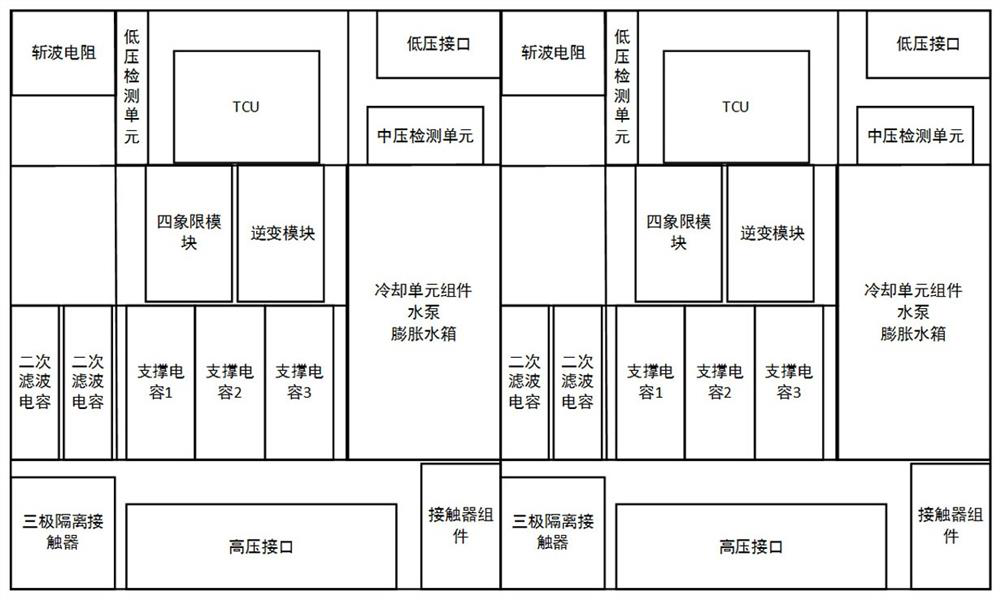

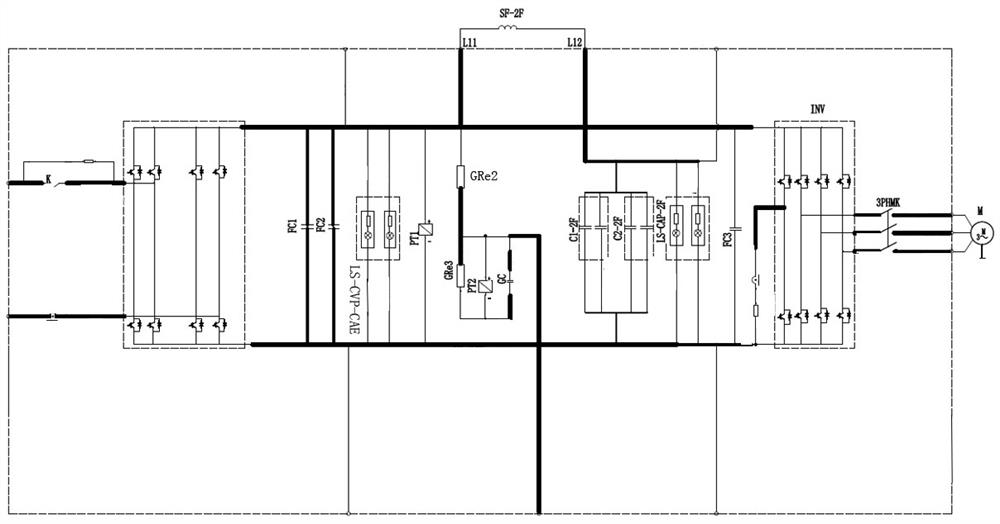

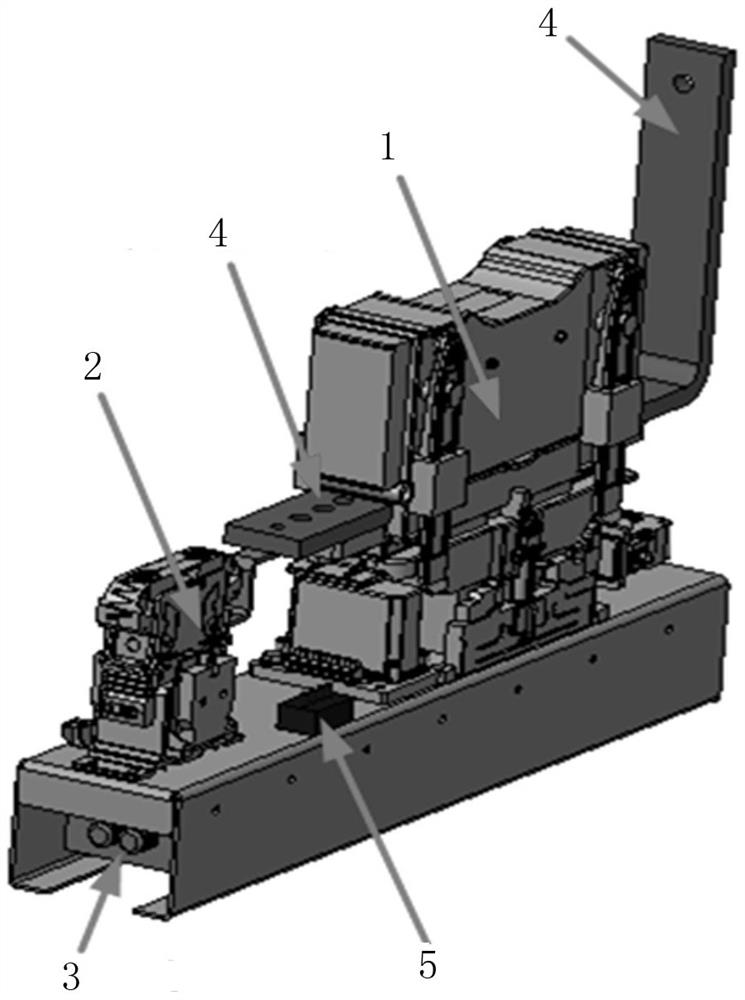

[0035] The traction converter cabinet of the specific embodiment is equipped with 2 sets of traction devices, and each set of traction devices consists of 1 pre-charging circuit, 1 four-quadrant power module, 1 set of intermediate circuit, 1 inverter power module and 1 isolation contactor Each traction device drives a permanent magnet synchronous motor (axis control). The electrical principle and structure of the two sets of traction devices are identical, and the cooling systems are independent of each other, increasing the redundancy of the system.

[0036] On the basis of the converter of this scheme, modular expansion can be carried out according to the needs, for example, it can be expanded to 3 sets of traction devices, and the cooling system can choose a shared water cooling system or an independent water cooling system.

[0037] The auxiliary converter takes power from the intermediate DC link of the 2nd axis (or 4th axis) of the traction converter. The intermediate ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com