Food can bottom grinding machine

A technology for grinding machines and food cans, which is applied in the direction of grinding frames, grinding machine parts, grinding slide plates, etc. Uncontrollable quality and other problems, to achieve the effect of stable feeding process and unloading process, convenient control and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

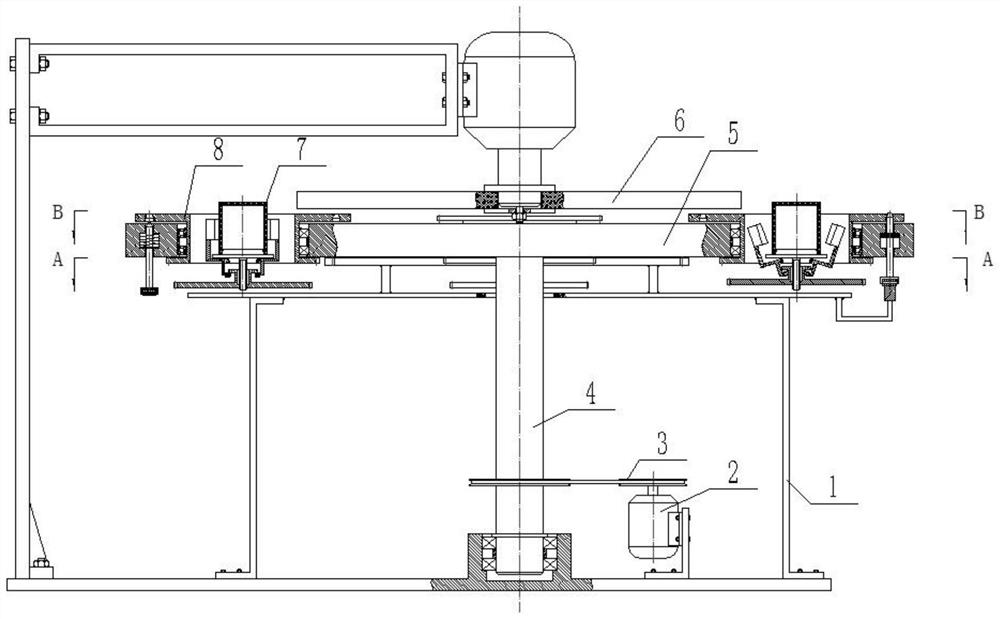

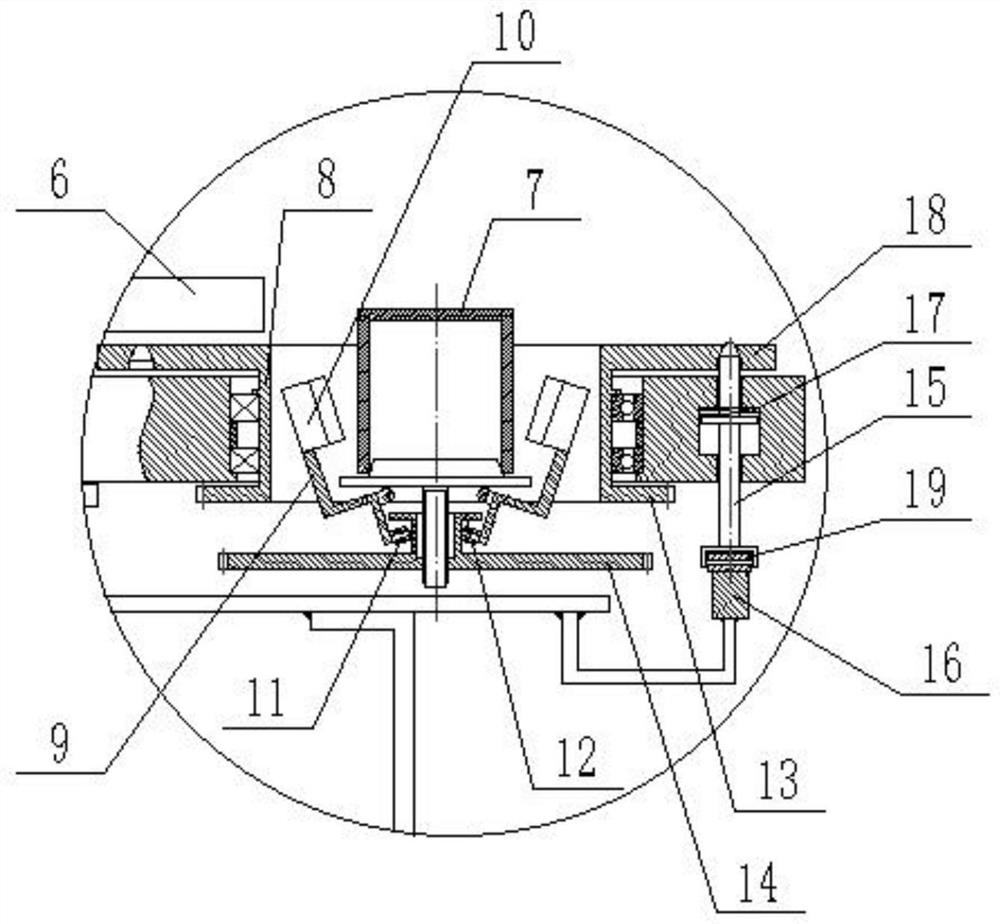

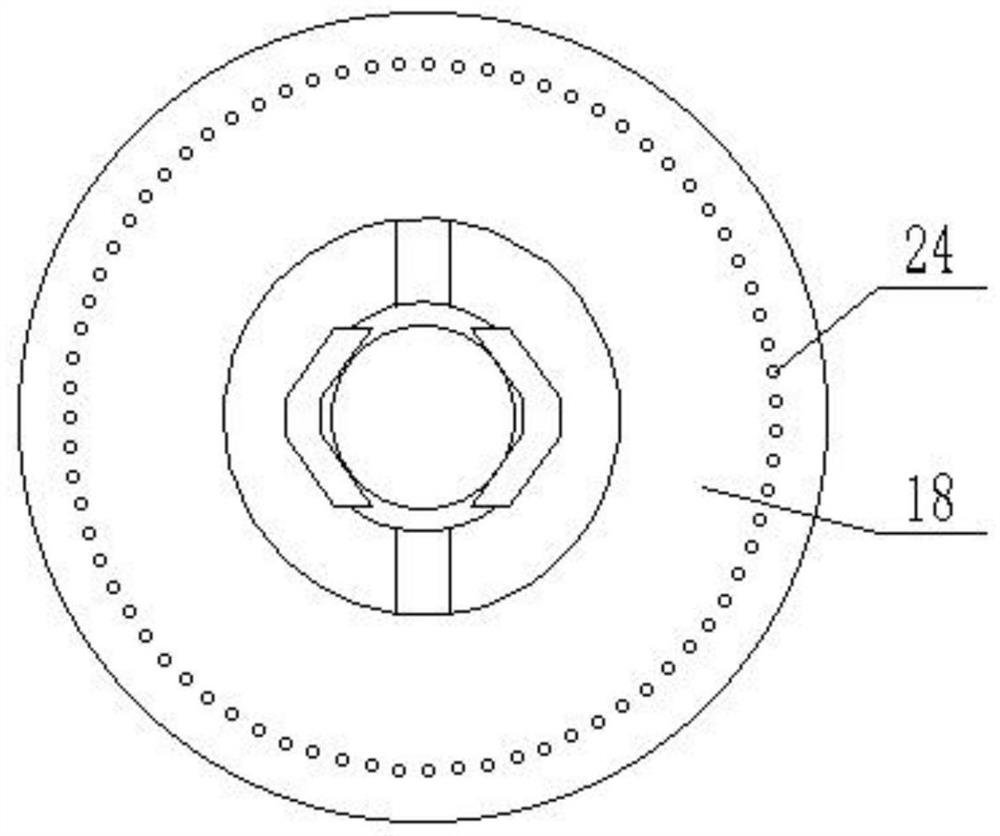

[0039] Such as Figures 1 to 8 As shown, a tank bottom welding gap grinder with pressing plate 10 pressed and top interlocked includes a rotating disc 5 bracket 1, a rotatable rotating disc 5 is arranged on the rotating disc 5 bracket 1, and the rotating disc 5 is connected with The main rotating shaft 4 is connected with the belt pulley pair 3 and the main driving motor 2 on the main rotating shaft 4, the main driving motor 2 preferably uses a servo motor, and the main driving motor 2 drives the main rotating shaft 4 and the rotating disk 5 to rotate through the belt pulley pair 3, and the rotation A rotatable clamping station is provided on the disk 5, and the rotatable clamping station is a certain distance away from the rotation center of the rotary disk, and the tank body 7 to be ground is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com