Indentation mechanism of partition-plate-free air filter, paper folding machine and use method

An air filter, no partition technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of improper installation of indentation knives, high indentation damage rate of filter paper, and high vertical degree of origami , to achieve the effect of ensuring uprightness, low rejection rate and uniform flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

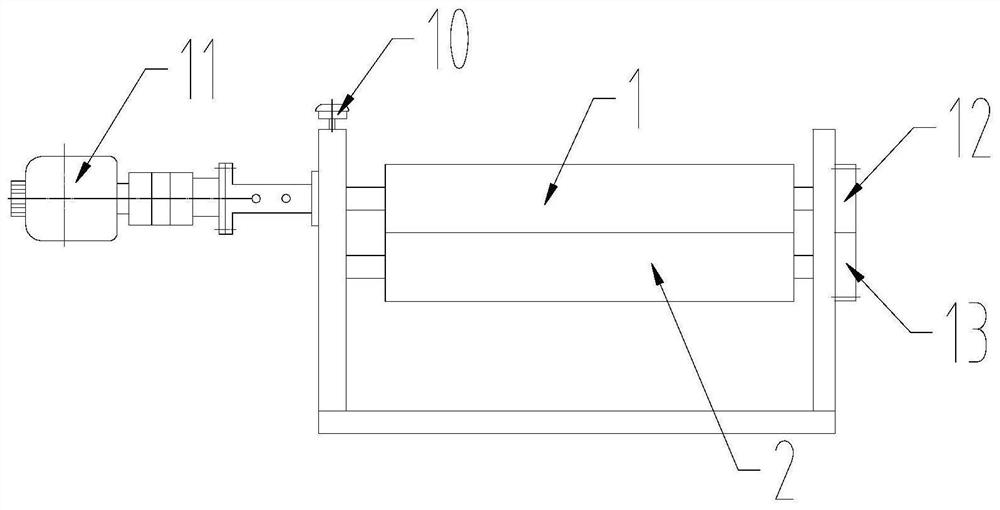

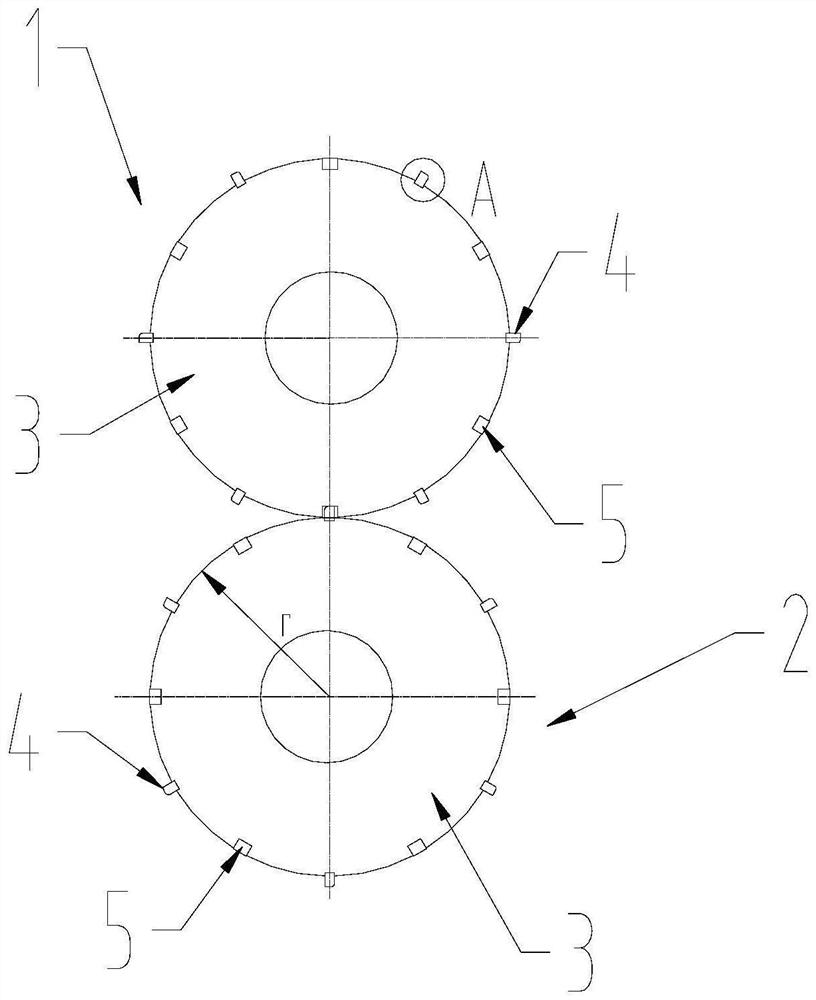

[0040] Such as figure 1 and 2 As shown, an indentation mechanism for an air filter without a partition includes a driving hob 1 and a driven hob 2 cooperating with the driving hob 1 , both of the driving hob 1 and the driven hob 2 include a drum 3 , On the side wall of the drum 3, hard cutter heads 4 are evenly distributed along the circumferential interval, and soft cutter heads 5 are arranged between adjacent hard cutter heads 4. The hard cutter heads 4 of the active hob 1 and the driven The soft cutter head 5 of the hob 2 is correspondingly matched, and the soft cutter head 5 of the active hob 1 is matched with the hard cutter head 4 of the driven hob 2 .

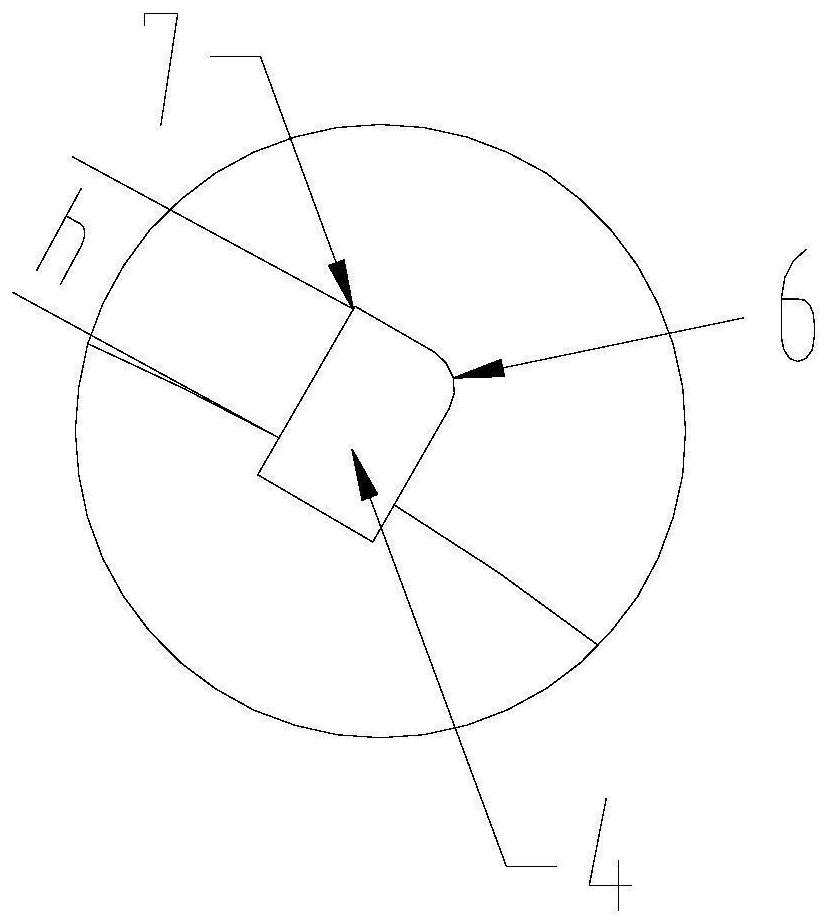

[0041] The paper feed edge 6 of the hard cutter head 4 is an arc surface, and the paper output edge 7 is a right-angled edge. The paper feeding edge 6 is a circular arc surface to prevent the hard cutter head 4 from cutting the filter paper, and the paper outlet edge 7 is a right-angled edge or a circular arc surface. ...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference is: as figure 2 As shown, the hard cutter head 4 and the soft cutter head 5 are all higher than the sidewall of the cylinder 3 in the radial direction, the radial height of the hard cutter head 4 is greater than the soft cutter head 5, and the circumferential direction of the hard cutter head 4 Width is less than soft cutter head 5.

[0045] The circumferential width of the soft cutter head 5 is 5-6mm, the radial cutter height is 0.08-0.15mm, the circumferential width of the hard cutter head 4 is 1.2-1.5mm, and the radial cutter height is 0.6-1.0mm. The arc of the paper feeding edge 6 of the hard cutter head 4 is 0.3 mm.

[0046] The design of the above structure makes the hob suitable for the processing of various filter papers, such as the H8-H10 filter material processing of high-efficiency air filters, which can not only reduce the breakage rate, but also make it easier to form indentations and ...

Embodiment 3

[0048] This embodiment is basically the same as embodiment one or two, the difference is: as Figure 3-5 As shown, the side wall of the drum 3 is evenly distributed along the circumferential direction with first installation grooves 8, and the drum 3 between adjacent first installation grooves 8 is provided with second installation grooves 9, first installation grooves 8 and second installation grooves 9 All along the axial direction of the drum 3, the root of the hard cutter head 4 is embedded in the first installation groove 8, and the extrusion groove 14 is formed by squeezing the roller 3 on both sides of the end of the hard cutter head 4, and the hard cutter head The cutter head 4 is fixed in the first installation groove 8 , and the soft cutter head 5 is detachably embedded in the second installation groove 9 . The soft cutter head 5 is a rubber cutter head, and the hard cutter head 4 is a metal cutter head.

[0049] The processing precision of the active hob 1 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com