Thermo-oxidative aging resistant regenerated polyethylene material as well as preparation method and application thereof

A technology of recycled polyethylene and polyethylene, which is applied in the field of recycling of renewable resources, can solve the problems of limiting the use range of optical cable sheaths, affecting the service life of optical cable sheaths, and large changes in elongation at break and tensile strength. Achieve excellent thermal and oxidative aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

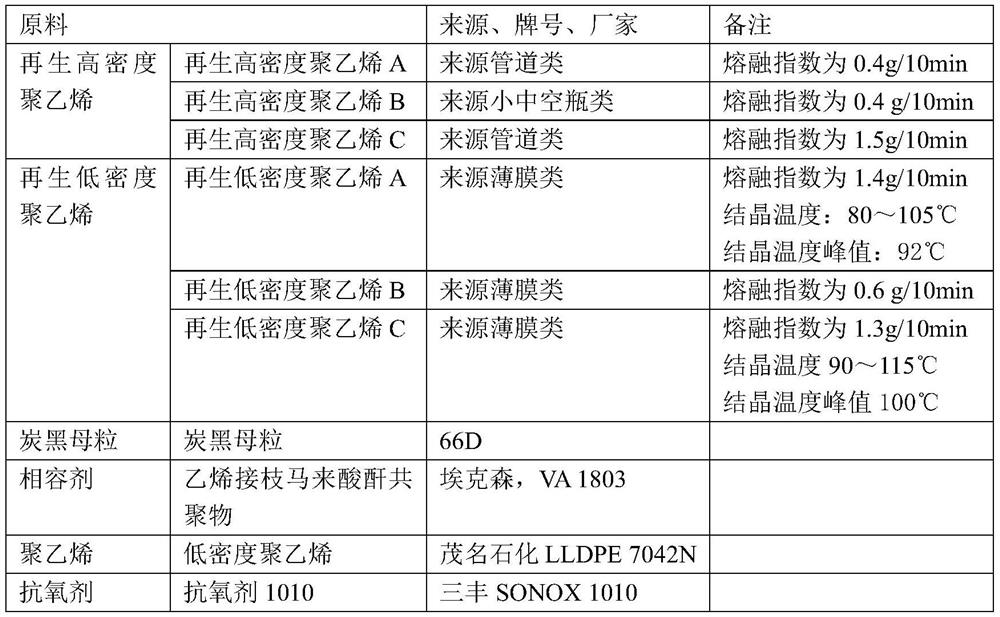

[0055] The contents of each component in the composite antioxidant masterbatches of Examples 1-5 are shown in Table 1.

[0056] Its preparation method is:

[0057] After mixing polyethylene, antioxidant, metal deactivator, nucleating agent and second lubricant according to Table 1, add them to the extruder, melt and mix, extrude and granulate to obtain the composite antioxidant Masterbatch.

[0058] The component content (parts by weight) of the composite antioxidant masterbatch of table 1 embodiment 1~5

[0059]

Embodiment 6~15

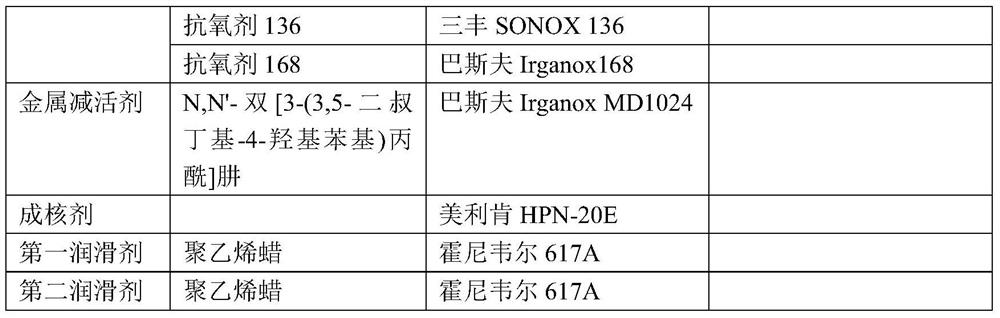

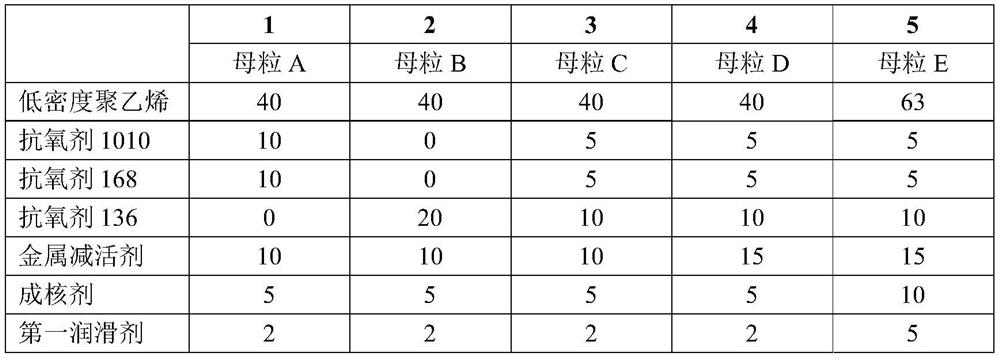

[0061] The content of each component in the recycled polyethylene materials of Examples 6-15 is shown in Table 1.

[0062] Its preparation method is:

[0063] According to Table 2, after mixing regenerated high-density polyethylene particles, regenerated low-density polyethylene particles, carbon black masterbatches, compatibilizers, composite antioxidant masterbatches, and the first lubricant, add them to the extruder, and melt Mixing, extruding and granulating to obtain the regenerated polyethylene material resistant to thermal and oxidative aging.

[0064] Among them, the extruder is a twin-screw extruder 75D, equipped with a dual-channel non-stop screen changer, the filter screen is 80-120 mesh; the extrusion temperature is 190-210°C, the screw speed is 450-550HZ, and the feeding amount is 350~400kg / h.

[0065] The component content (weight part) of the regenerated polyethylene material of table 2 embodiment 6~15

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com