A kind of preparation method of antioxidant modified carbon nanotube/hydrogenated nitrile rubber

A technology of hydrogenated nitrile rubber and carbon nanotubes, which is applied in the field of preparation of heat-resistant oxygen aging hydrogenated nitrile rubber, antioxidant modified carbon nanotubes/hydrogenated nitrile rubber, and can solve the problem of few reports and inconvenience of large-scale promotion , many environmental protection issues and other issues, to achieve the effect of simple preparation process, good thermal and oxidative aging resistance, and reduced self-polymerization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the antioxidant modified carbon nanotube / hydrogenated nitrile rubber of the present invention specifically comprises the following steps:

[0032] (1) Mix concentrated sulfuric acid and concentrated nitric acid, add multi-walled carbon nanotubes (MWCNTS) to the mixed acid, and carry out a high temperature reaction. The high temperature reaction temperature is 70-150°C, and the reaction time is 1-6h. The carbon nanotubes are washed with water until neutral and dried; wherein the volume ratio of concentrated sulfuric acid and concentrated nitric acid is one of 1:1, 2:1, 3:1 or 4:1. The washing method is one or more of centrifugal washing, suction filtration washing or vacuum distillation.

[0033](2), the carbon nanotubes and antioxidant obtained in step (1) are 1:0.3-1 by mass ratio, above the melting point of the antioxidant, use a mechanical force field to mix, and react for 30-50min, Taking out the product, washing off the unreacted antioxid...

Embodiment 1

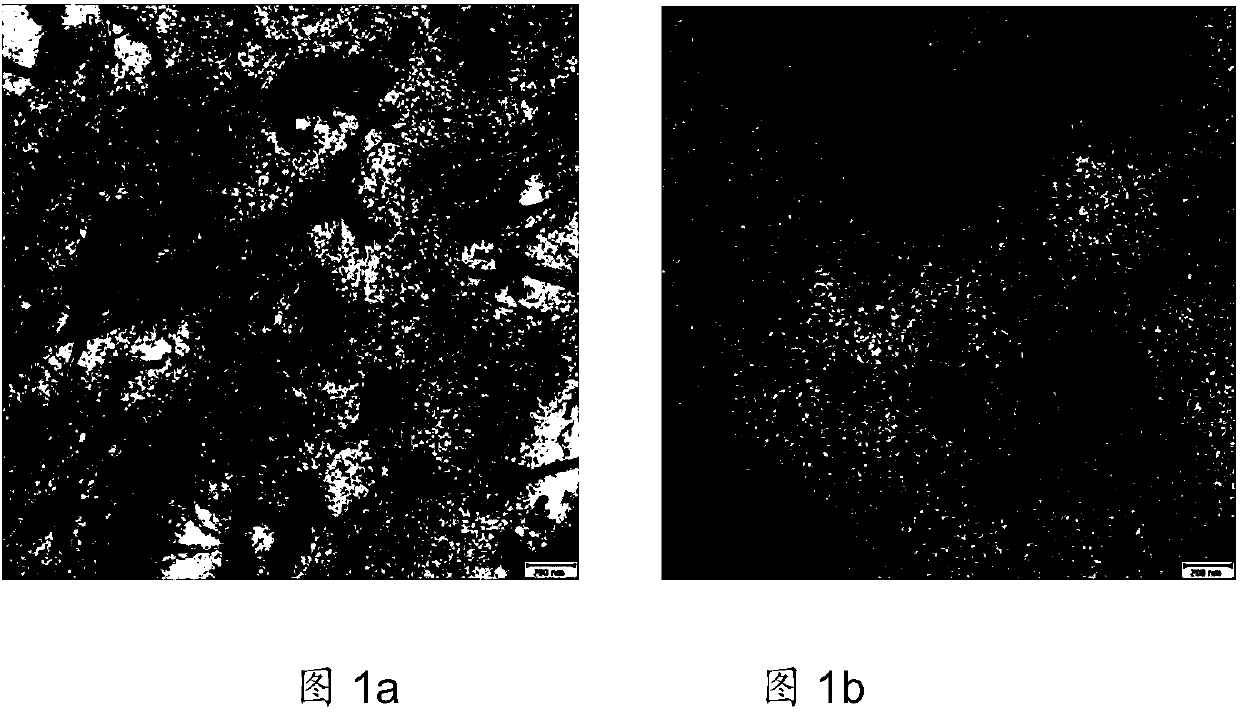

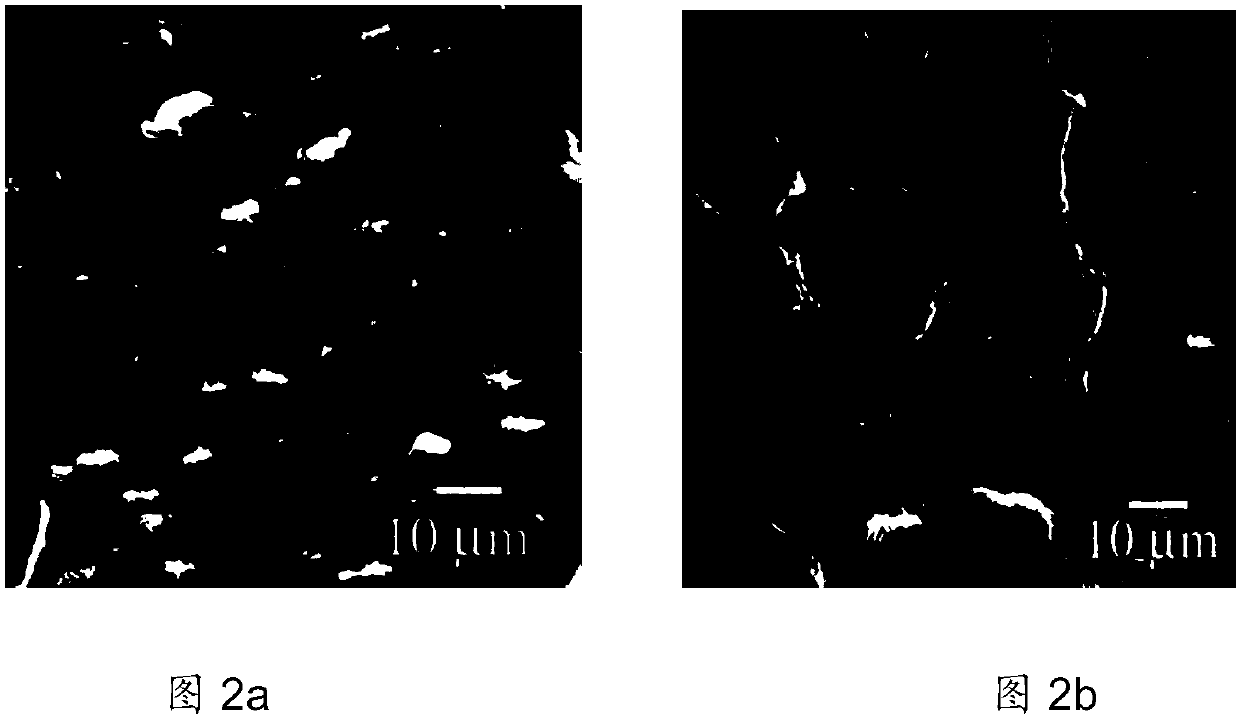

[0043] (1) Preparation of functional carbon nanotubes

[0044] Weigh 120 g of multi-walled carbon nanotubes, and at the same time weigh 4500 mL of concentrated sulfuric acid and 1500 mL of concentrated nitric acid into a 10L beaker, stir mechanically for 30min, transfer the mixture to a 10L three-necked flask, and condense and reflux at 120°C for 3h. After the temperature in the flask was lowered to room temperature, the activated carbon nanotubes were centrifuged and washed with a large amount of distilled water until neutral, and then placed in a vacuum drying oven and dried at 80° C. for 24 hours. The mass concentrations of concentrated sulfuric acid and concentrated nitric acid were 98% and 68%, respectively.

[0045] 100 g of activated carbon nanotubes and 50 g of hindered phenol AO-80 were weighed and pre-mixed, and then mechanically mixed at 140 °C for 30 min in a Hack rheometer, and the product was taken out and cooled to room temperature. The cooled product was centr...

Embodiment 2

[0054] (1) Preparation of functional carbon nanotubes

[0055] 120 g of multi-walled carbon nanotubes were weighed, and 4500 mL of concentrated sulfuric acid and 1500 mL of concentrated nitric acid were placed in a 10L beaker, and the mixture was mechanically stirred for 30min. After the temperature in the flask was lowered to room temperature, the activated carbon nanotubes were centrifuged and washed with a large amount of distilled water until neutral, and then placed in a vacuum drying oven and dried at 80° C. for 24 hours. The mass concentrations of concentrated sulfuric acid and concentrated nitric acid were 98% and 68%, respectively.

[0056] 100 g of activated carbon nanotubes and 50 g of hindered phenolic AO-80 were weighed and pre-mixed, and then mechanically mixed at 150 °C for 50 min in a Hack rheometer, and the product was taken out and cooled to room temperature. The cooled product was centrifuged and washed with a large amount of DMF, and then continued to be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com