High-performance organic-inorganic composite heat-reflection waterproof coating, preparation method and application

An inorganic composite and waterproof coating technology, which is applied in the direction of reflection/signal coating, alkali metal silicate coating, coating, etc., can solve the problems of poor thermal insulation performance, poor weather resistance, insufficient adhesion and strength, etc.

Inactive Publication Date: 2021-05-04

广东龙湖科技股份有限公司

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The coating of the invention is green and environmentally friendly, with excellent physical properties; polyvinyl acetate emulsion, acrylic emulsion, fly ash, titanium dioxide and other raw materials are added, so that the coating has the advantages of good elasticity,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

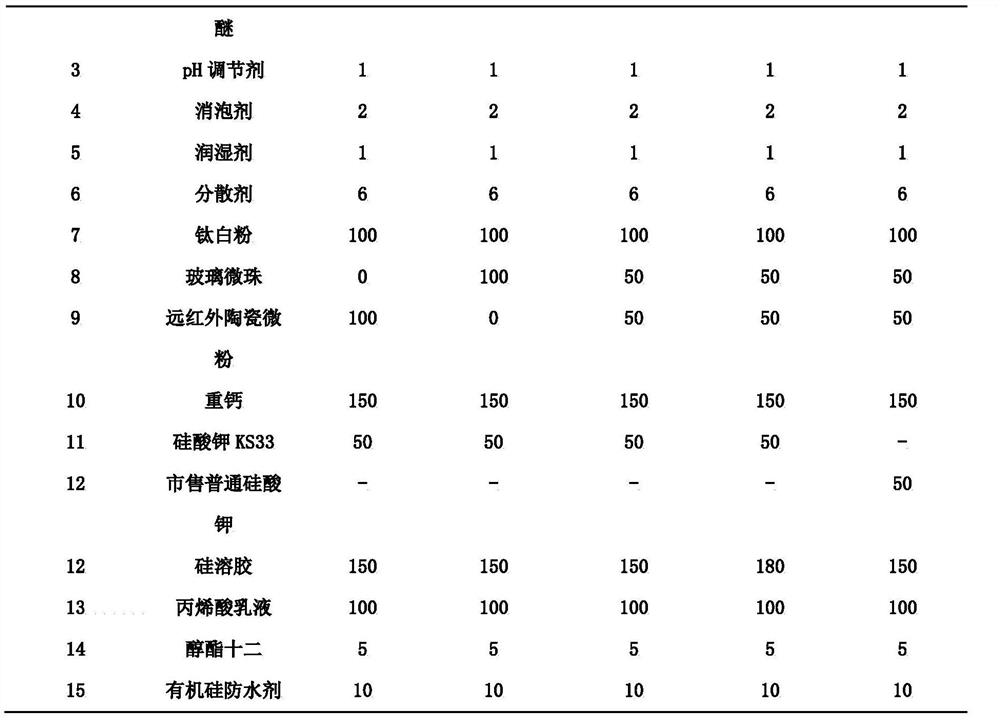

The invention relates to a high-performance organic-inorganic composite heat-reflection waterproof coating, a preparation method and application. The high-performance organic-inorganic composite heat-reflection waterproof coating is prepared from the following components in percentage by weight: 5 to 10 percent of potassium silicate, 15 to 20 percent of silica sol, 10 to 15 percent of acrylic emulsion, 3.0 to 5.0 percent of glass beads, 5.0 to 10 percent of far infrared ceramic powder, 12 to 15 percent of titanium dioxide, 15 to 20 percent of pigment filler, 0.4 to 0.6 percent of thickening agent, 0.1 to 0.2 percent of pH regulator, 0.5 to 0.7 percent of dispersing agent, 0.1 to 0.2 percent of wetting agent, 0.1 to 0.2 percent of defoaming agent, 0.5 to 0.8 percent of coalescing agent, 0.5 to 1 percent of organic silicon waterproof agent and the balance of water. The composite heat-reflection waterproof coating has relatively strong adhesive force and relatively strong water resistance, provides an effective and lasting protection effect for a wall body, and expands the application of the composite heat-reflection waterproof coating in the field of external wall heat insulation.

Description

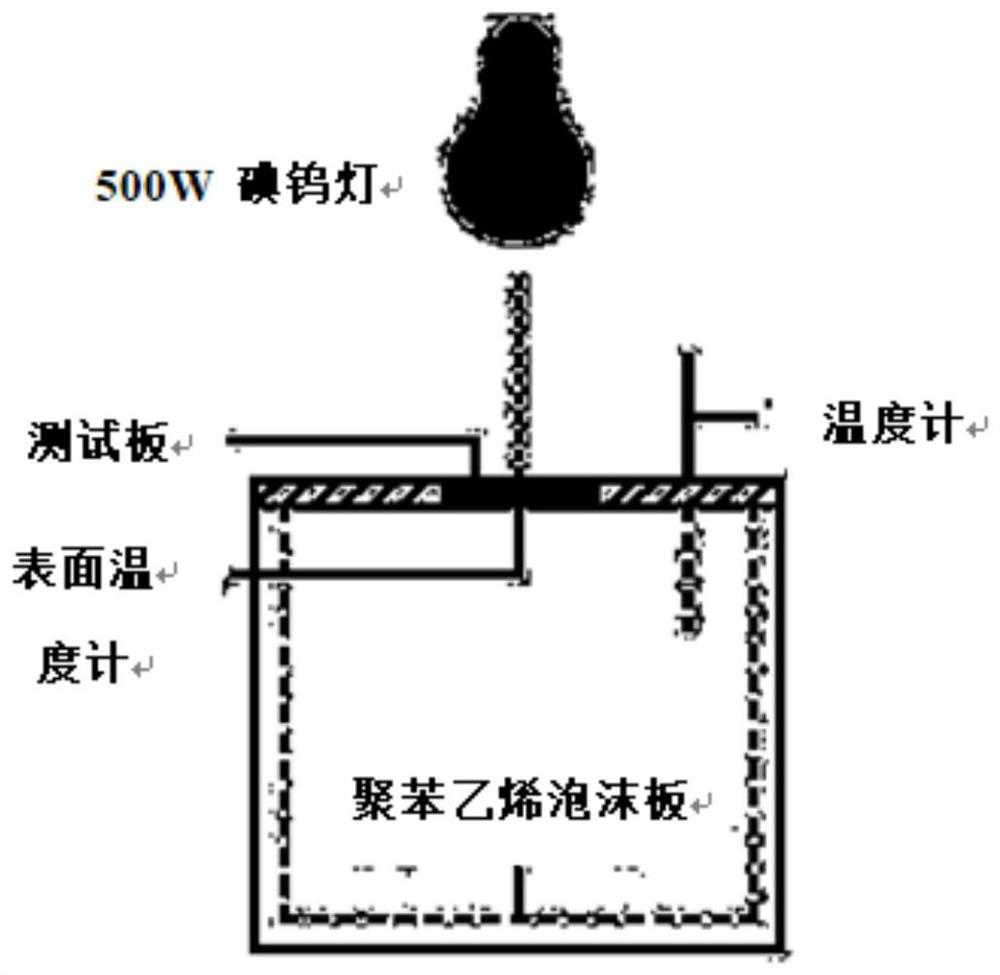

technical field [0001] The invention belongs to the field of architectural coatings, and in particular relates to a high-performance organic-inorganic composite heat-reflecting waterproof coating, a preparation method and an application. Background technique [0002] With the rapid development of my country's economy, the country's requirements for energy conservation and environmental protection are getting higher and higher. The emission reduction in the construction field can be achieved through building energy conservation. Therefore, the development and promotion of thermal insulation coatings for building exterior walls that take into account both thermal insulation and thermal insulation effects are of great significance for reducing the use of refrigeration equipment, reducing energy consumption, and saving social energy. However, there are many types of thermal insulation coatings available in China, and the quality is uneven, so it is difficult to achieve efficient...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D133/04C09D5/33C09D1/04C09D1/00C09D7/61C09D7/62

CPCC08K2003/2241C08K2003/265C08K2003/3045C09D1/00C09D1/04C09D5/004C09D133/04C09D7/61C09D7/62C09D7/70C08K9/04C08K7/20C08K3/22C08K9/02C08K3/00C08K13/06C08K3/26C08K3/34C08K3/30

Inventor 李荣毅罗慧严煌洪永顺

Owner 广东龙湖科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com