Waterproof asphalt pavement structure and construction method thereof

An asphalt pavement and bitumen technology, which is applied in the field of waterproof asphalt pavement structure and its construction, can solve problems such as adverse effects on the base layer, frost heave damage of the pavement structure, frost heave of the cushion layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

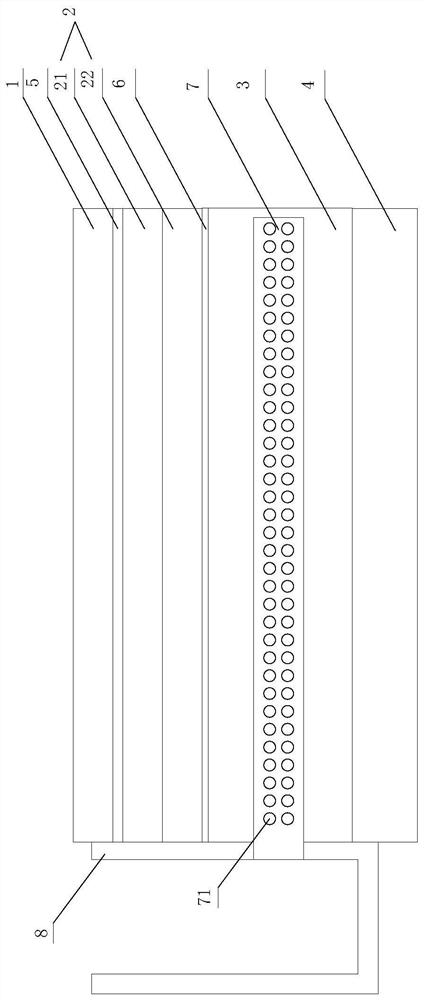

[0031] see figure 1, a waterproof asphalt pavement structure, comprising an asphalt wear surface layer 1, an asphalt middle and lower layer 2, a roadbed surface layer 3, and a roadbed 4, and a waterproof adhesive is arranged between the asphalt wear surface layer 1 and the asphalt middle and lower layer 2 Layer 5, an impermeable see-through seal layer 6 is set between the lower layer 2 of the asphalt and the roadbed surface layer 3, and the roadbed surface layer 3 is provided with drainage pipes 7 arranged at intervals along the length direction of the road surface, and the drainage pipe 7 is provided with drainage holes 71 in the circumferential direction , the length direction of the drainage pipe 7 is consistent with the width direction of the road surface, a drainage ditch 8 is arranged on one side of the road surface width direction, the drainage ditch 8 is arranged along the length direction of the road surface, the lower side of the drainage ditch 8 extends to the subgra...

Embodiment 2

[0041] see figure 1 , a waterproof asphalt pavement structure, comprising an asphalt wear surface layer 1, an asphalt middle and lower layer 2, a roadbed surface layer 3, and a roadbed 4, and a waterproof adhesive is arranged between the asphalt wear surface layer 1 and the asphalt middle and lower layer 2 Layer 5, an impermeable see-through seal layer 6 is set between the lower layer 2 of the asphalt and the roadbed surface layer 3, and the roadbed surface layer 3 is provided with drainage pipes 7 arranged at intervals along the length direction of the road surface, and the drainage pipe 7 is provided with drainage holes 71 in the circumferential direction , the length direction of the drainage pipe 7 is consistent with the width direction of the road surface, a drainage ditch 8 is arranged on one side of the road surface width direction, the drainage ditch 8 is arranged along the length direction of the road surface, the lower side of the drainage ditch 8 extends to the subgr...

Embodiment 3

[0057] A construction method for a waterproof asphalt pavement structure, comprising the following steps:

[0058] (1) First build the subgrade 4, then pave the pavement base layer evenly and evenly on the upper surface of the subgrade 4, the pavement base layer is laid layer by layer, and the pavement base layer is laid by artificially burying the drainage pipe 7, and ensuring that the drainage pipe 7 is on one side in the length direction low altitude;

[0059] (2) After the pavement base layer is laid, clean up the waste material in the drain pipe 7, and lay the asphalt middle and lower layer 2 and the see-through seal layer 6;

[0060] (3) After the asphalt middle and lower layer 2 is laid, the waterproof adhesive layer 5 is evenly sprayed on the asphalt middle and lower layer 2, and wait for the demulsification and evaporation of the emulsified asphalt;

[0061] (4) After the emulsified asphalt demulsification and evaporation are completed, lay the asphalt abrasive surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com