Simple testing device for electric control oil injector

A test device and lubricator technology, applied in the direction of lubricating parts, adding/discharging lubricant, engine flow, etc., can solve the problems of large test area, complex control principle, power waste, etc., to ensure test accuracy and simple system structure , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiments of the present invention, and will be described, and the embodiments described in the embodiments of the present invention will be described. It is a part of the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are the scope of the present invention.

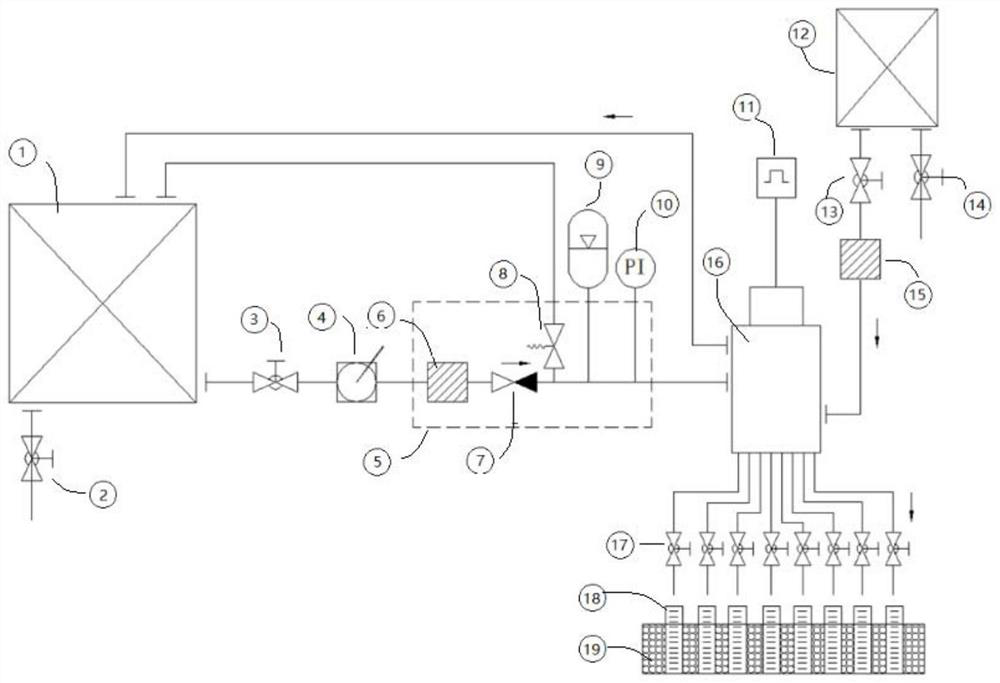

[0018]Seefigure 1, A simple test device for electronically controlled injection, simple testing device includes a hydraulic oil tank 1, a hydraulic oil oil supply valve 3, a hydraulic pump 4, a storage block assembly 5, a pulse signal generator 11, a lubricant gravity fuel tank 12, lubricating oil The oil supply valve 13, the oil filter 15, the drain va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com