Busbar terminal and IGBT power module

A busbar terminal and busbar technology, applied in the field of power semiconductor devices, can solve the problems of metal fatigue in non-welded parts, inability to cope with the reliability problems of strong thermoelectric stress and high electromagnetic torque, uneven residual stress, etc., to enhance the electromagnetic torque resistance. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

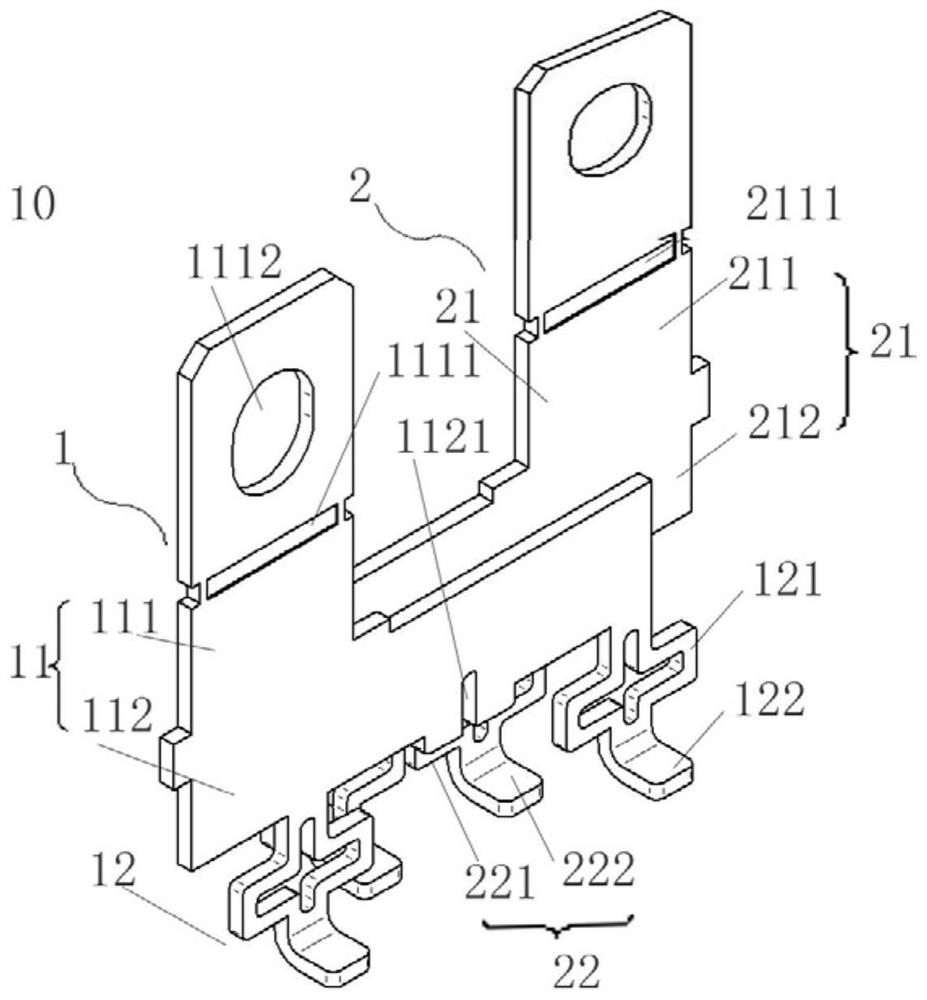

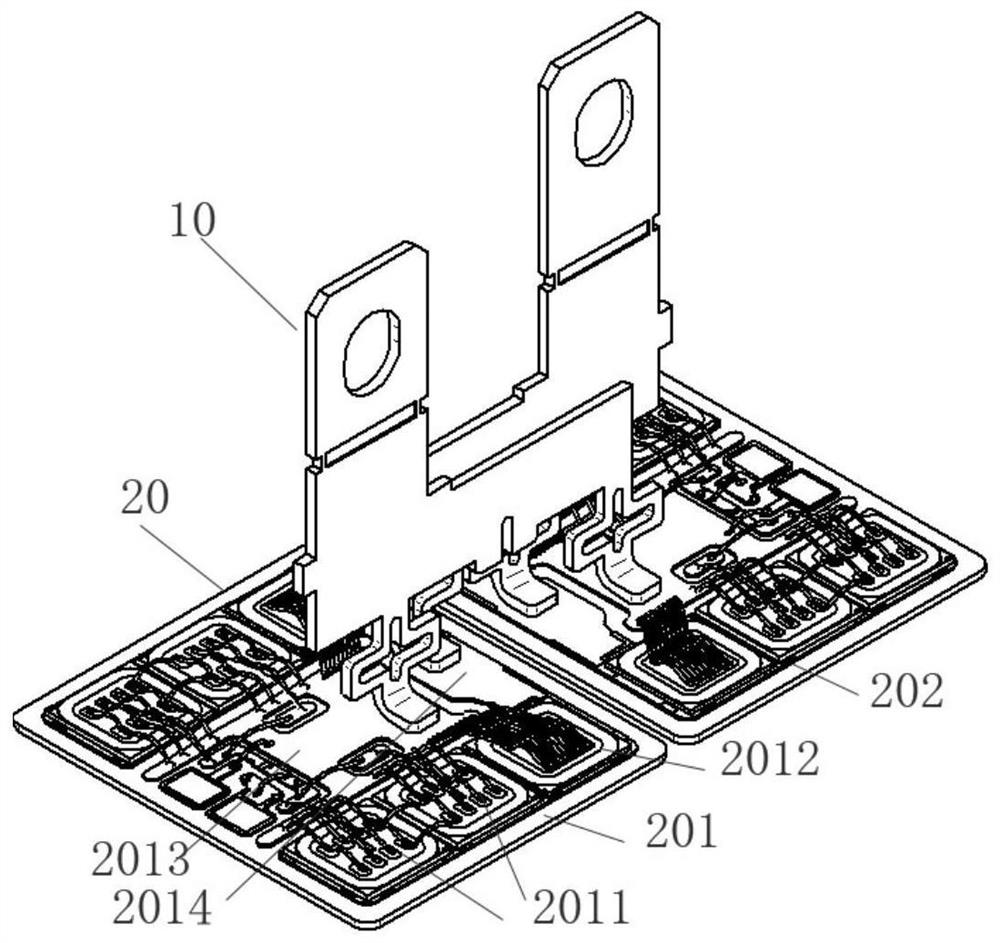

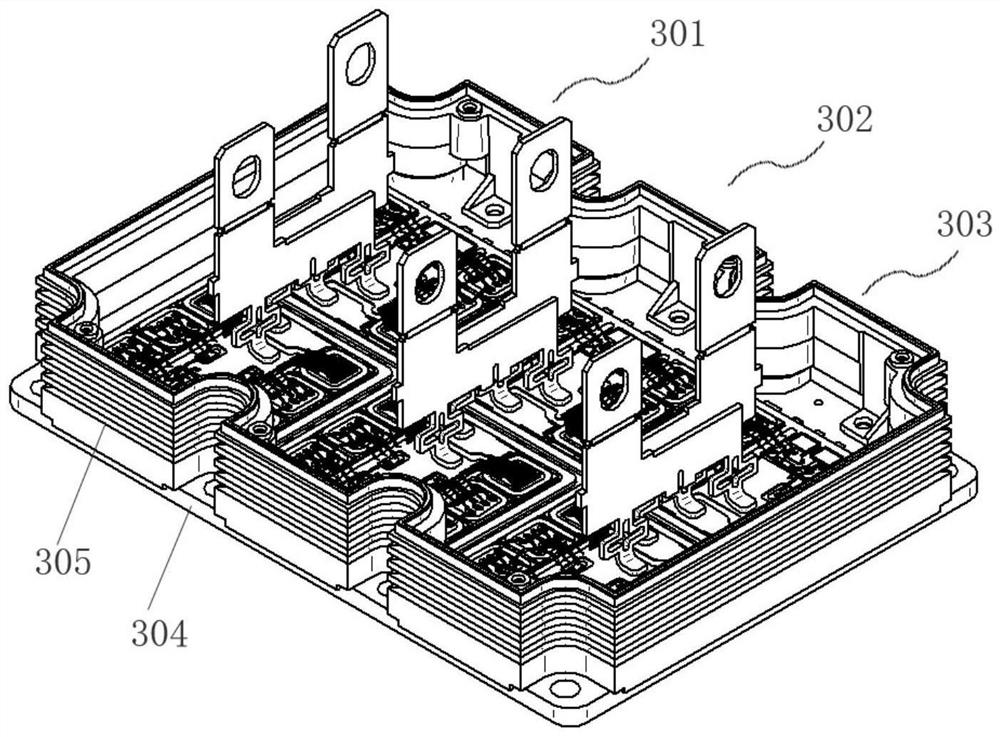

[0033] like figure 1 As shown, a busbar terminal 10 according to the present application is shown. like figure 1 As shown, the busbar terminal 10 includes an emitter busbar 1 and a collector busbar 2. Both the emitter busbar 1 and the collector busbar 2 include a main body part 11, 21 and a Pins 12,22. Wherein, the pin 12,22 includes the tube ankle portion 121,221 connected with the main body portion 11,21, and the end portion 122,222 connected with the tube ankle portion 121,221, the tube ankle portion 121,221 and the end portion 122,222 are located in different planes, that is, the tube ankle portion There is an angle between 121, 221 and tip 122, 222 which is not 180 degrees. Preferably, the tube ankle portion 121, 221 and end portion 122, 222 are at 90 degrees.

[0034] exist figure 1 In the illustrated embodiment, the longitudinal section of the tube ankle portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com