Adapter

An adapter and connector technology, which is applied in the directions of instruments, connections, and components of connecting devices, can solve problems such as increased cost and inability to test the electrical performance of adapters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

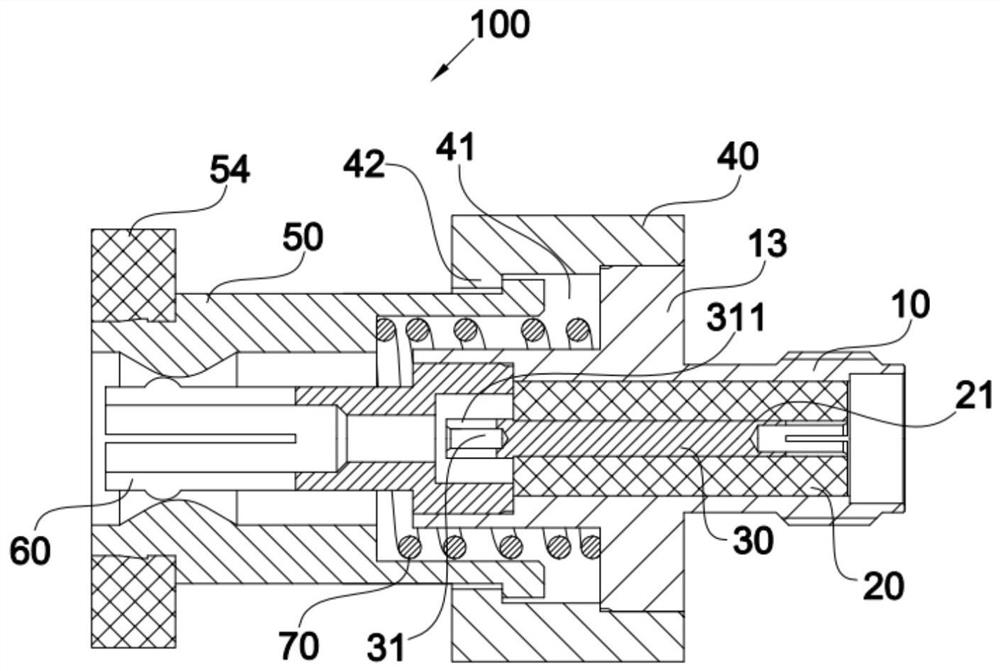

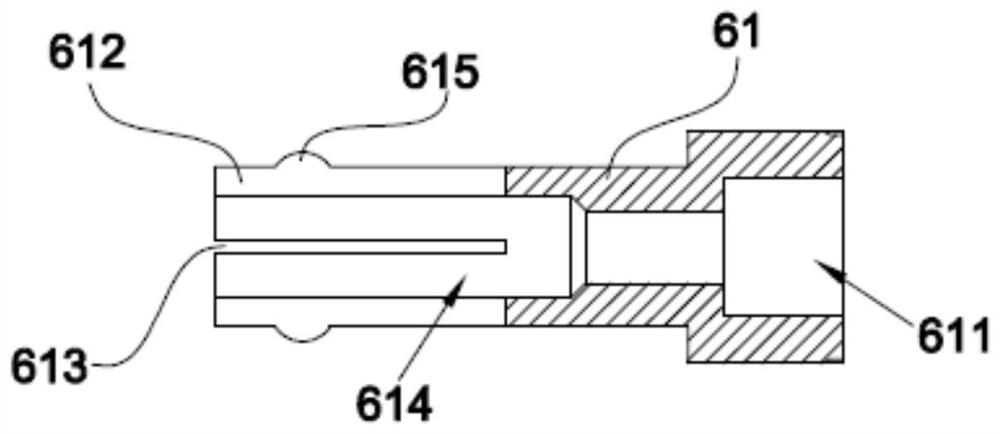

[0056] Such as Figure 5 As shown, a single-ended cable assembly consists of a cable and a connector attached to one end of the cable. Before mating the single-ended cable assembly with the adapter 100, it is necessary to process the butt end of the cable, that is, the end not connected to the connector, so that the cable core a, the cable outer conductor c, and the cable outer conductor c Insulation medium b between cable core wire a. When connecting the adapter 100, press the pressing part 54 on the outside of the locking part 50 to move the locking part 50 in the axial direction, the locking part 50 squeezes the elastic part 70, and the elastic part 70 is compressed. 55 no longer acts on the resisting portion 615 of the plurality of elastic clamping portions 612, and the plurality of elastic clamping portions 612 are in a state of expansion; further inserting the cable, during the insertion of the cable into the adapter 100, the cable core wire a passes through Insert the...

Embodiment 2

[0058] Such as Figure 6 As shown, after the two ends of the cable are processed, the cable core wire a, the cable outer conductor c and the insulating medium b between the cable outer conductor and the cable core wire appear. After processing, the process of connecting the cable to the adapter 100 is detailed in Embodiment 1, and will not be repeated here. For some larger cables, such as 141 cables, 250 cables, or 1 / 2 feeders, etc., it is only necessary to adjust the size of the inner conductor 30 and the elastic clamping piece 60 of the adapter to suit the above cables. The structure and working principle of the adapter remain unchanged.

Embodiment 3

[0060] combine Figure 8 and Figure 9 As shown, the cable assembly with parts at the tail includes a cable, a first part and a second part d, wherein the tail of the cable is provided with the second part d, and the outer diameter of the second part d is larger than the outer diameter of the cable The outer diameter of the conductor c, the second part d is a conductor, which can be installed at the tail of the cable by welding. Before the adapter 100 is connected, the inner conductor 30 and the elastic clip 60 in the adapter 100 are replaced, and the elastic clip 60 is replaced with an elastic clip with a receiving space. When connecting the adapter 100, press the pressing part 54 on the outside of the locking part 50 to move the locking part 50 in the axial direction. No longer acting on the multiple elastic clamping parts 612, the multiple elastic clamping parts 612 are in a state of expansion; further inserting the cable assembly with parts, during the insertion of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com