Bimetal composite pipe welding method and product thereof

A bimetallic composite pipe and welding method technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of complex production process of bimetallic composite pipe, insufficient welding performance accuracy and high cost, and achieve flexible process. High performance and applicability, improved performance and welding efficiency, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

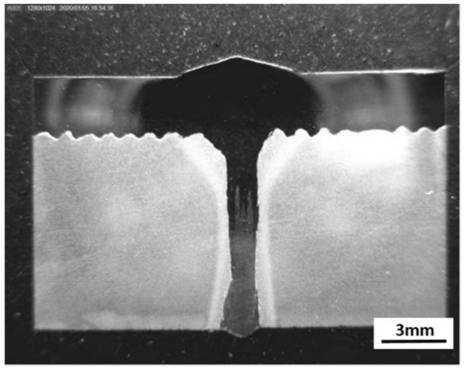

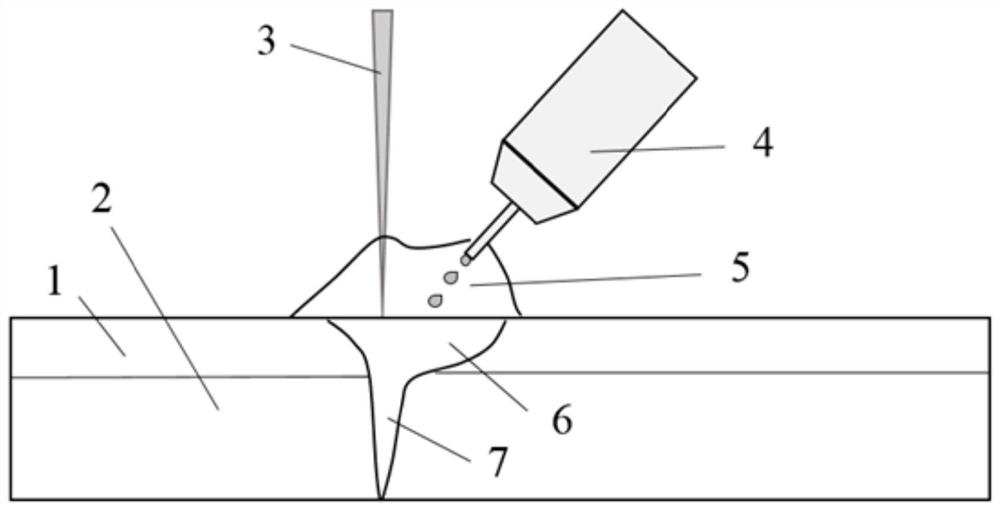

[0039] In this embodiment, the thickness of the composite plate is 6mm+2mm for the composite layer + base layer, wherein the composite plate layer 1 is 2mm 304 stainless steel, the composite plate base layer 2 is 6mm Q235 steel, and the welding groove is I-shaped, that is, no additional artificial Processing groove. Laser-arc hybrid welding adopts laser-single arc hybrid welding, and the welding wire is ER309L. The above composite sheet is processed into a composite pipe.

[0040] Specifically include the following steps:

[0041] S1: Process I-shaped grooves on the parts to be welded on both sides of the bimetallic composite plate;

[0042] S2: The bimetal composite sheet is continuously fed into the spiral tube forming unit, gradually bent into a tube shape, and forms a spiral seam, wherein the seam gap is less than 0.3mm;

[0043] S3: Use laser-arc hybrid welding to weld the stainless steel on the inner side of the spiral tube to the clad plate weld to form a laser-arc h...

Embodiment 2

[0048] In this embodiment, the thickness of the composite plate + the base layer + the layer is 8mm+2mm+2mm, wherein the first layer 1-1 and the second layer 1-2 are 2mm 304 stainless steel, and the base layer 2 is 8mm Q235 steel, the welding groove is I-shaped. Laser-single arc hybrid welding is adopted, the welding wire is ER309L, and the powder used for laser cladding of the cover layer is 308L.

[0049] Specifically include the following steps:

[0050] S1: Process I-shaped grooves on the parts to be welded on both sides of the bimetallic composite plate;

[0051] S2: The bimetallic composite sheet is continuously fed into the spiral tube forming unit and gradually bent into a tube shape, forming a spiral seam, where the seam gap is less than 0.3mm;

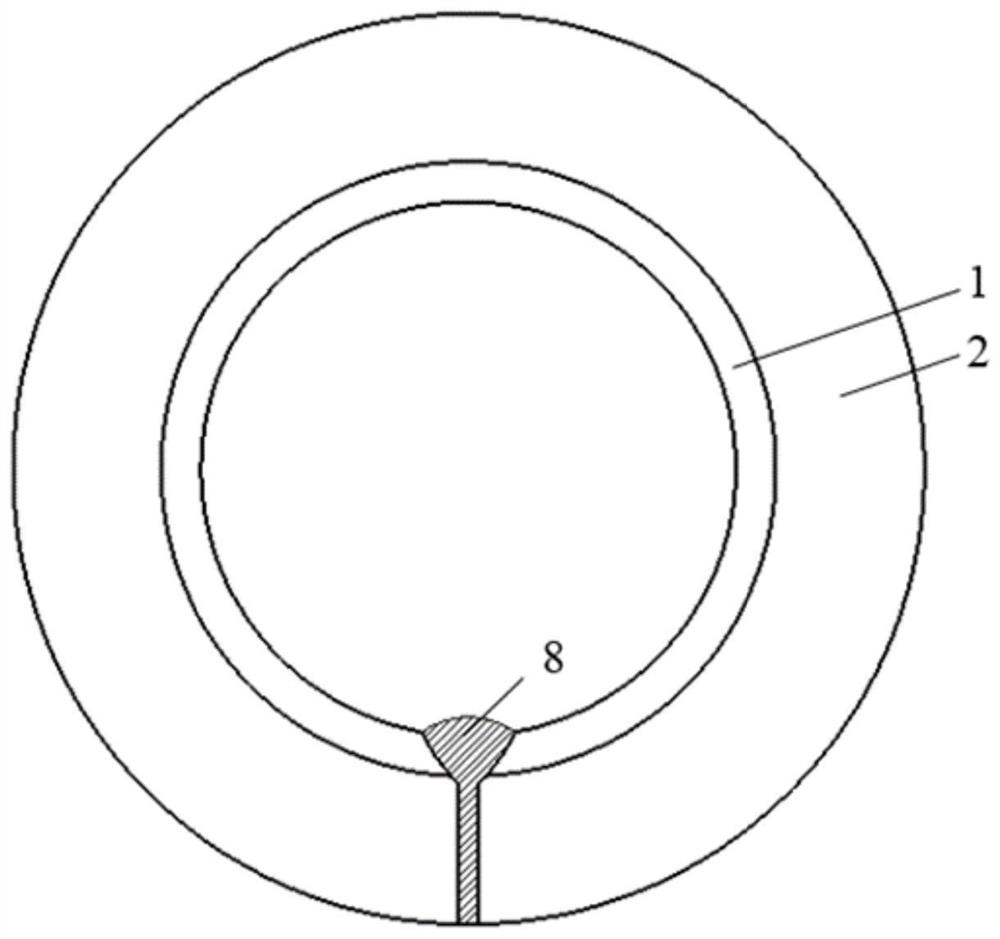

[0052] S3: Use laser-arc hybrid welding to weld the weld seam of the composite plate on the stainless steel surface inside the spiral tube to form a laser-arc hybrid weld seam 8 . Figure 4 It is a schematic diagram of las...

Embodiment 3

[0060] In this embodiment, the thickness of the composite plate is (10+2) mm, wherein the cladding layer 1 of the composite plate is 2 mm 304 stainless steel, the base layer 2 of the composite plate is 6 mm Q235 steel, and the welding groove is I-shaped. Laser-arc hybrid welding adopts laser-single arc hybrid welding device, welding wire is ER309L,

[0061] Specifically include the following steps:

[0062] S1: Process I-shaped grooves on the parts to be welded on both sides of the bimetallic composite plate;

[0063] S2: The bimetallic composite sheet is formed into a straight seam tubular shape and a spiral seam through the JCOE forming process, and the seam gap is less than 0.4mm;

[0064] S3: Laser-arc hybrid welding is used to weld the stainless steel on the inner side of the spiral tube to the weld of the composite plate to form a laser-arc hybrid welding weld 8, and complete the welding of the entire bimetallic composite spiral tube. Among them, the laser-arc hybrid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com