Perforated current collector foil preparation method and device based on staggered texturing rolling

A current collector and foil technology, applied in the field of electrochemical energy storage, can solve the problems of complex etching process, burrs on the foil surface, and high cost of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

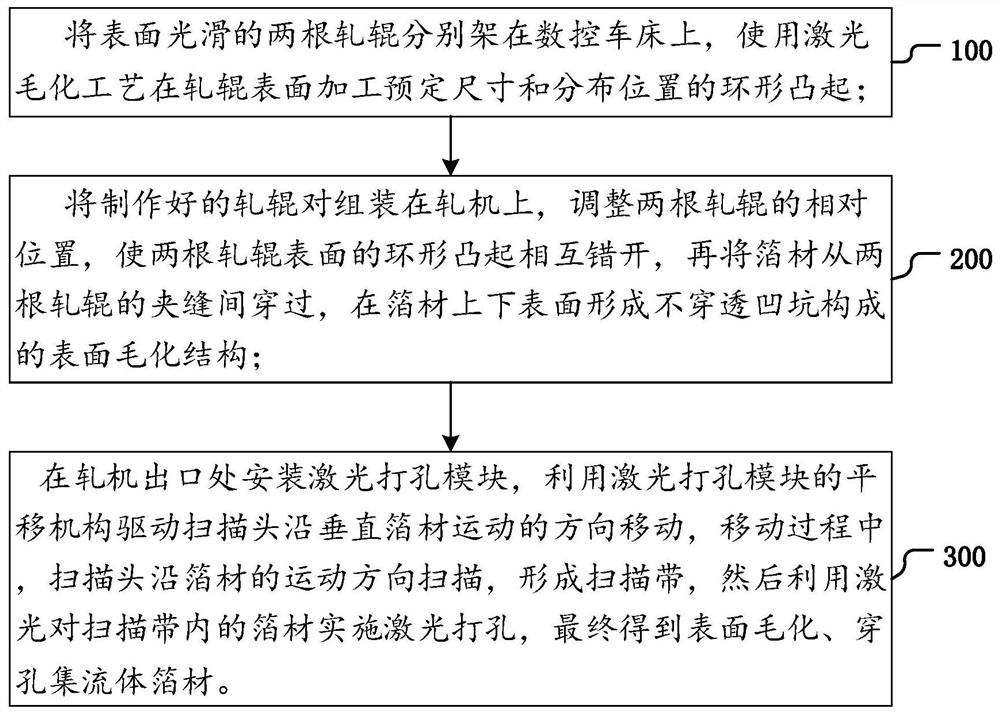

[0022] Such as figure 1 As shown, in one embodiment of the present invention, a method and device for preparing a perforated current collector foil based on dislocation texture rolling are disclosed. The preparation method includes the following steps:

[0023] Step 100, placing two rolls with smooth surfaces on a CNC lathe respectively, and processing ring-shaped protrusions of predetermined size and distribution position on the surface of the rolls using a laser texturing process;

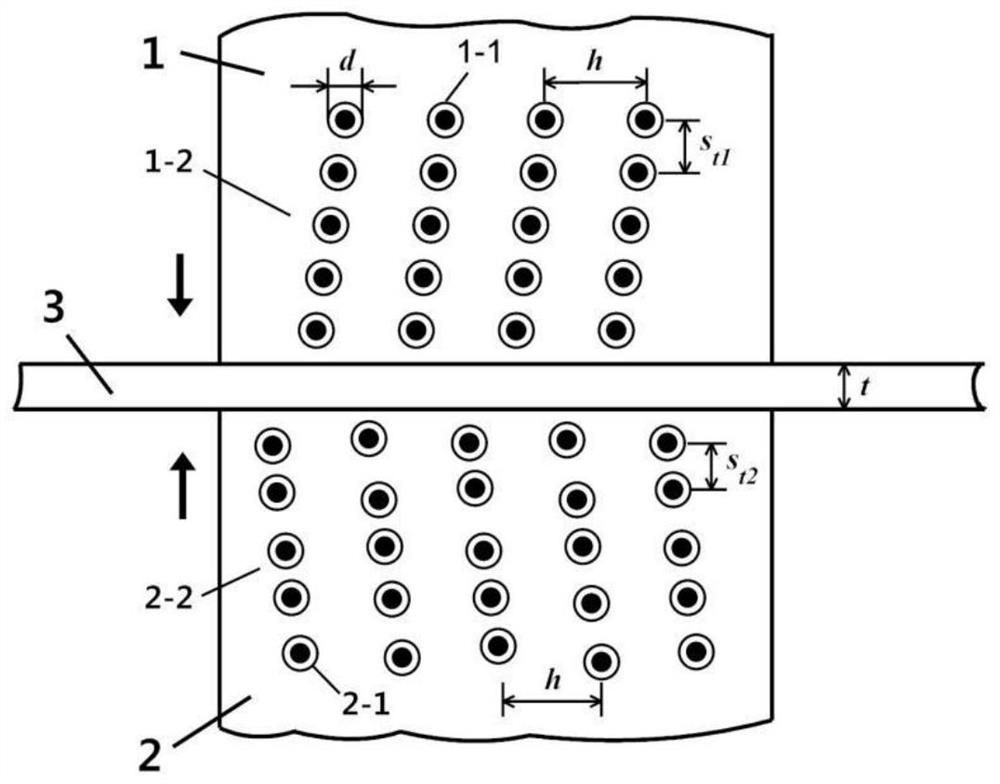

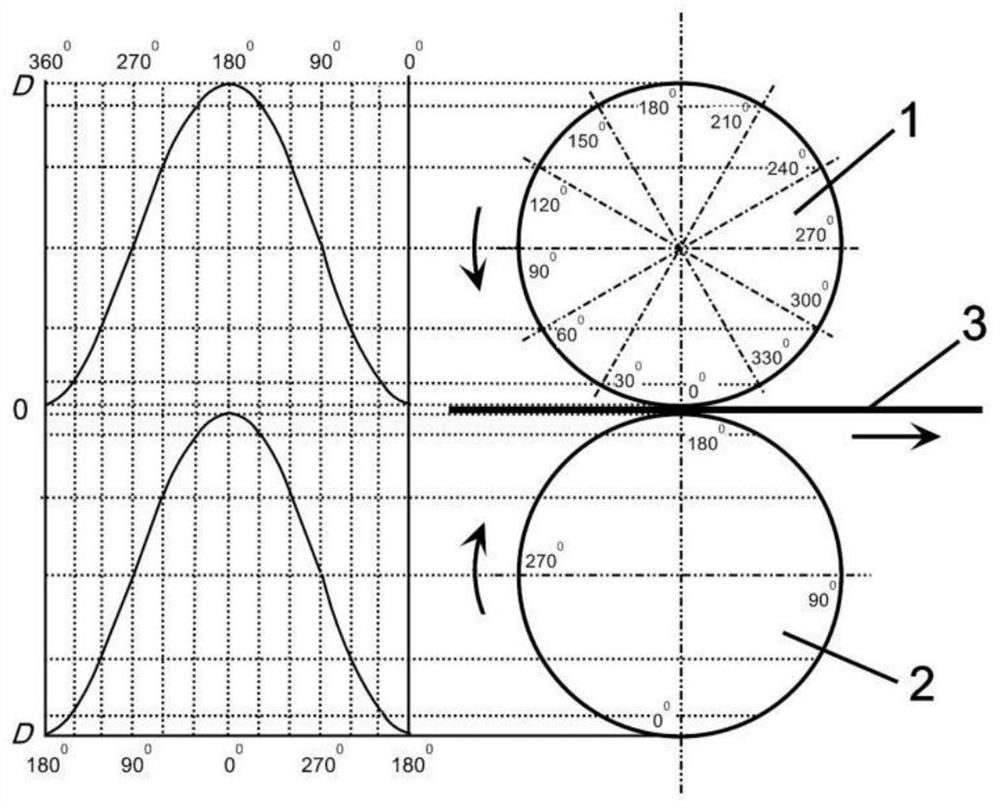

[0024] In this step, the roll pairs are respectively processed along the helical trajectory with the same laser texturing parameters, forming ring-shaped protrusions 1-1 and 2-1 with the same height and diameter on the surfaces of the two rolls 1 and 2, but the two The helical lines on the surfaces of rolls 1 and 2 rotate in opposite directions, such as figure 2 As shown, the circumferential distances between the annular protrusions 1-1 on the surface of one of the rolls 1 are fixed, and the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com