Flexible gantry type robot welding system for steel formwork

A robot welding and gantry technology, applied in the field of steel formwork manufacturing, can solve the problems of flexible production operations that cannot meet non-standard orders, unstable quality of manual welding products, single welding products, etc., so as to improve flexible welding capabilities and improve welding quality. , the effect of production beat control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

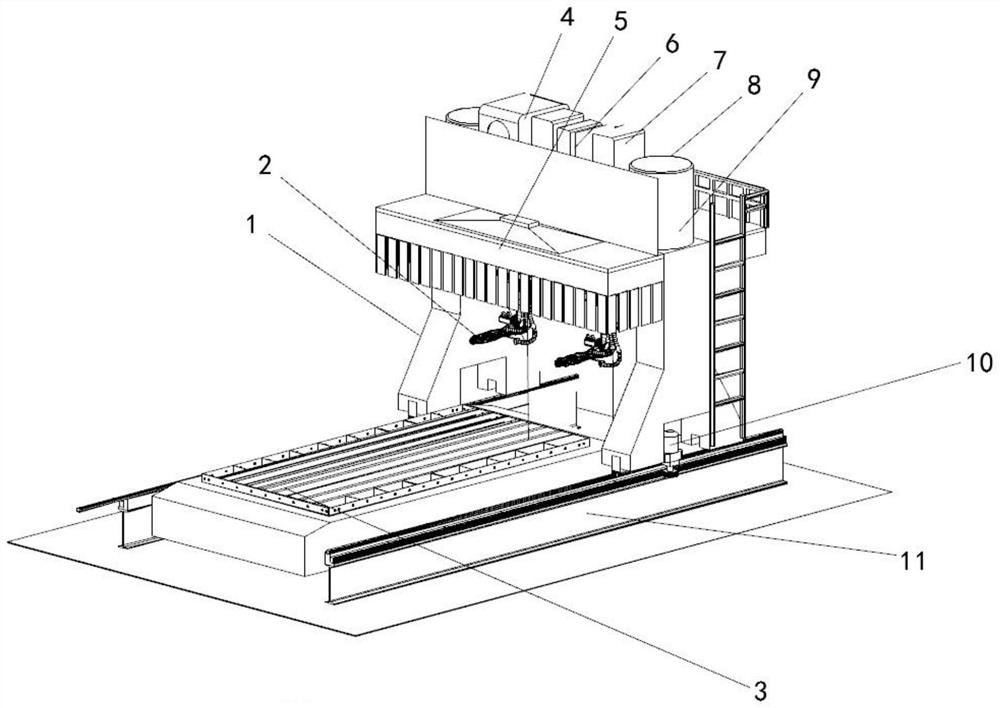

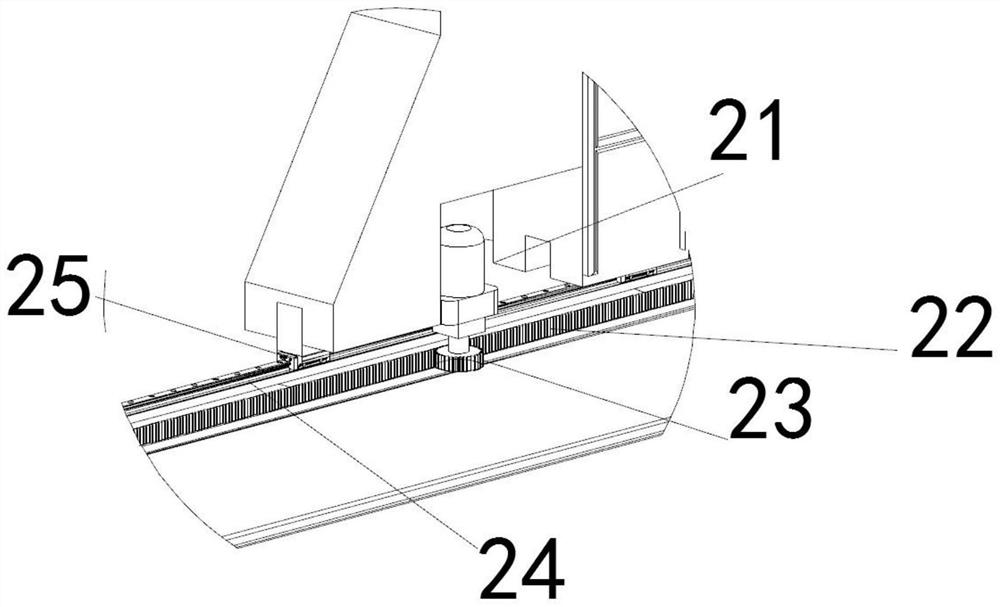

[0023] combine Figure 1-3 As shown, a steel formwork flexible gantry robot welding system includes a welding robot 2 and parallel and symmetrically arranged walking tracks 11, a welding platform 3 is arranged between the walking tracks 11, and a walking device 10 passes through the walking track 11. A gantry 1 is connected, and the top of the gantry 1 is connected with a dust removal device 4, a control electric box 6, a water cooling device 7, a welding power source 8 and a welding wire bucket 9, and the welding robot 2 is connected to the gantry 1 upside down. One side of the gantry 1 is located above the welding robot 2 and is provided with a dust removal cover 5 matched with the dust removal device 4 .

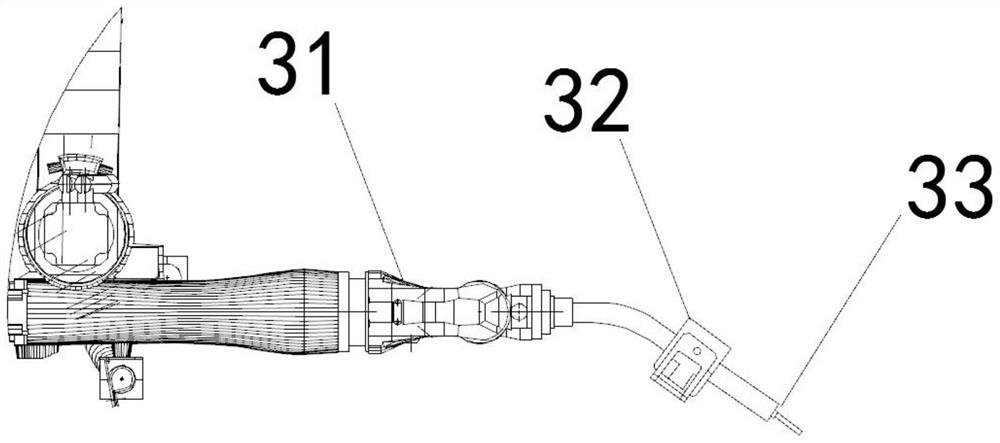

[0024] The end of the welding robot 2 is connected with a welding torch head 33 through a connecting piece 31. The welding torch head 33 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com