Preparation method of self-repairing composite insulator

A composite insulator, self-healing technology, used in household components, applications, coatings, etc., can solve problems such as residual internal stress, decline in mechanical and insulating properties of insulators, and composite material damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

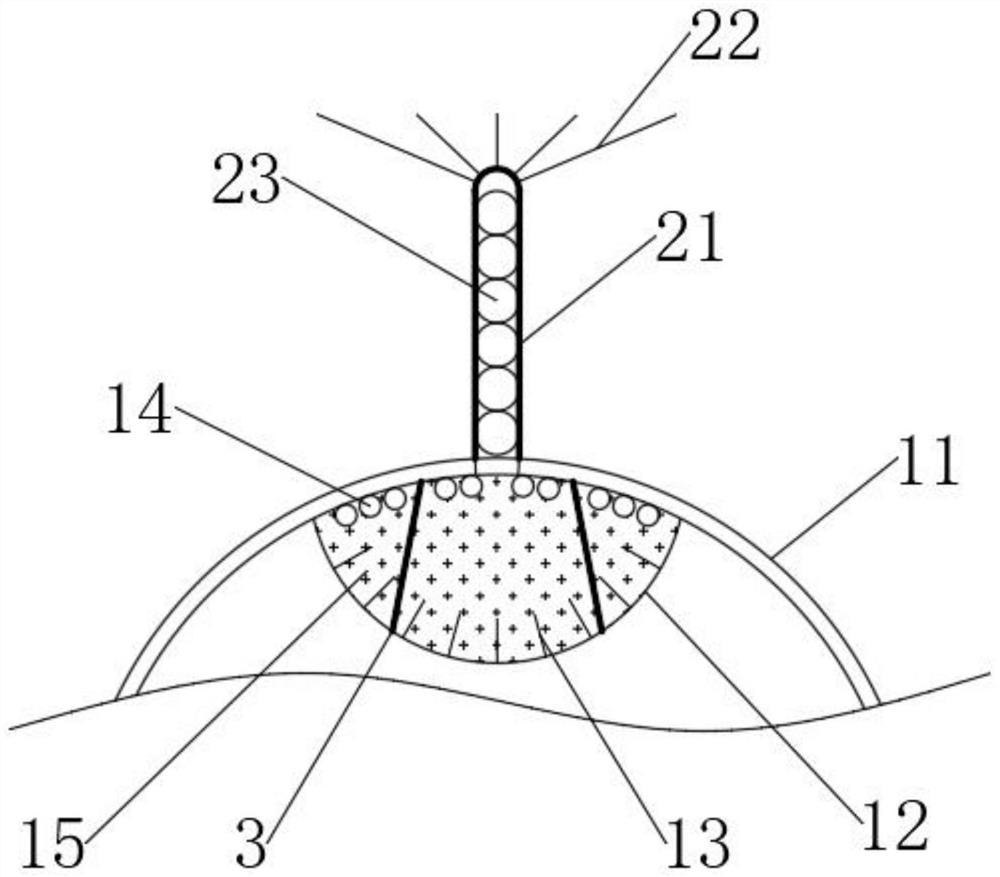

[0048] see figure 1 , a method for preparing a self-repairing composite insulator, comprising the following steps:

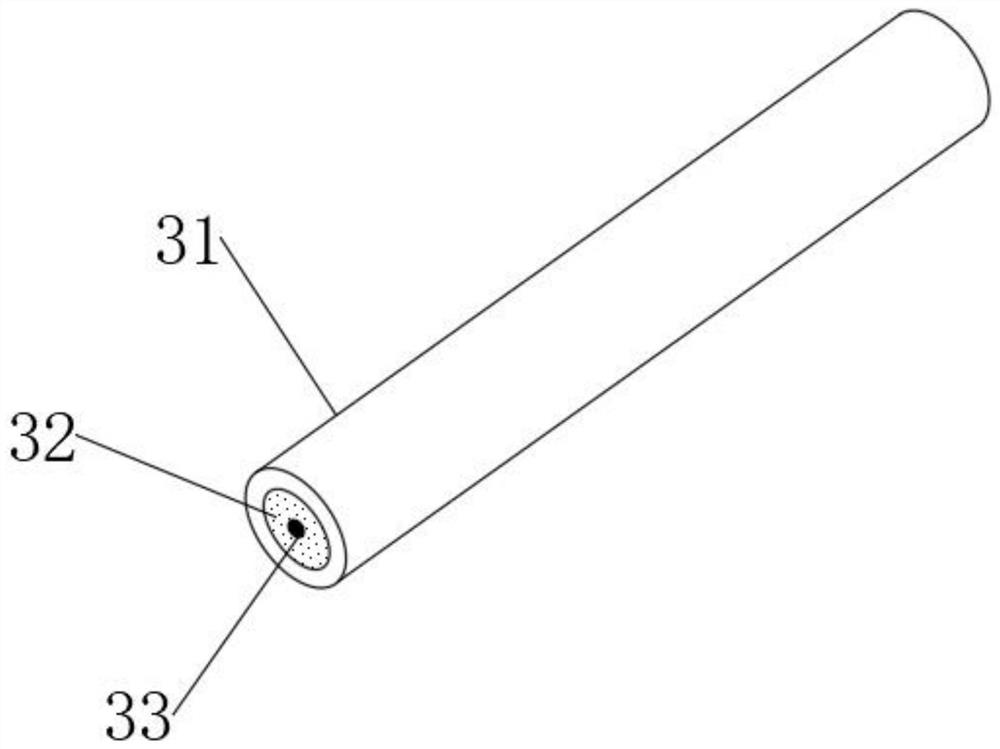

[0049] S1. Take insulating fiber bundles to make a three-dimensional skeleton that matches the shape of the insulator, and then prepare resin glue and self-repairing microspheres;

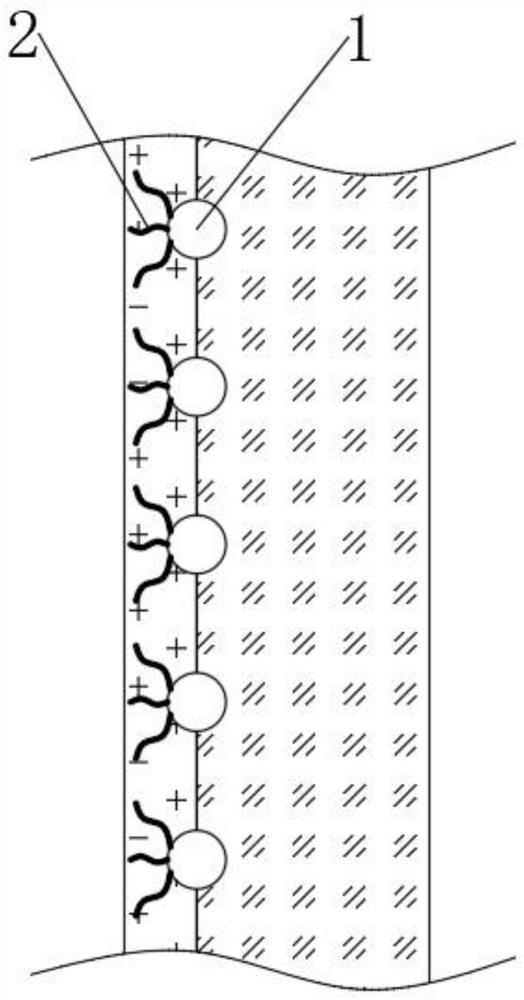

[0050] S2. The self-healing microspheres should be no less than 4 pieces / 10cm 2 The density is dispersed and wound on the surface of the three-dimensional skeleton, and the resin glue is placed in a vacuumized container, and the mixture is obtained by degassing at a vacuum degree of 0-0.5MPa for 20 minutes;

[0051] S3. Preheat the pouring mold to 60°C, heat the mixture to 40°C and store it at a constant temperature for later use, and place the three-dimensional skeleton at the center of the mold;

[0052] S4. Slowly inject the mixture into the casting mold. After completion, apply a magnetic field of appropriate strength to the three-dimensional skeleton outside the mold to guide ...

Embodiment 2

[0068] A method for preparing a self-repairing composite insulator, comprising the following steps:

[0069] S1. Take insulating fiber bundles to make a three-dimensional skeleton that matches the shape of the insulator, and then prepare resin glue and self-repairing microspheres;

[0070] S2. The self-healing microspheres should be no less than 4 pieces / 10cm 2 The density is dispersed and wound on the surface of the three-dimensional skeleton, and the resin glue is placed in a vacuumized container, and the mixture is obtained by degassing at a vacuum degree of 0-0.5MPa for 25 minutes;

[0071] S3. Preheat the pouring mold to 60°C, heat the mixture to 50°C and store it at a constant temperature for later use, and place the three-dimensional skeleton at the center of the mold;

[0072] S4. Slowly inject the mixture into the casting mold. After completion, apply a magnetic field of appropriate strength to the three-dimensional skeleton outside the mold to guide and extend the s...

Embodiment 3

[0078] A method for preparing a self-repairing composite insulator, comprising the following steps:

[0079] S1. Take insulating fiber bundles to make a three-dimensional skeleton that matches the shape of the insulator, and then prepare resin glue and self-repairing microspheres;

[0080] S2. The self-healing microspheres should be no less than 4 pieces / 10cm 2 The density is dispersed and wound on the surface of the three-dimensional skeleton, and the resin glue is placed in a vacuumized container, and the mixture is obtained by degassing at a vacuum degree of 0-0.5MPa for 30 minutes;

[0081] S3. Preheat the pouring mold to 60°C, heat the mixture to 60°C and store it at a constant temperature for later use, and place the three-dimensional skeleton at the center of the mold;

[0082] S4. Slowly pour the mixture into the casting mold. After completion, apply a magnetic field of appropriate strength to the three-dimensional skeleton outside the mold to guide and extend the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com