Battery replacing robot

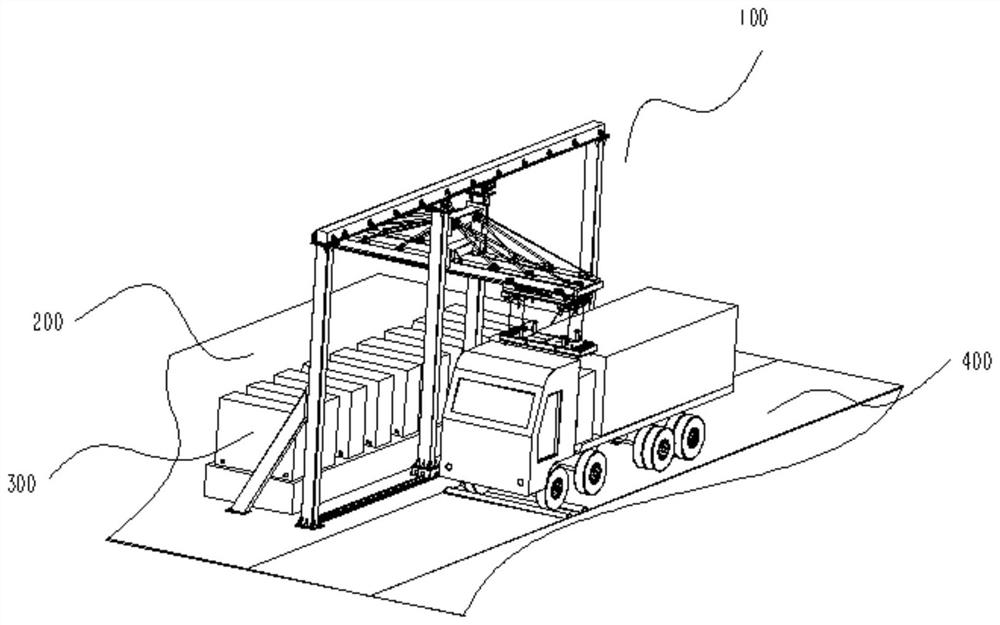

A battery swapping robot and transmission mechanism technology, which is applied in cranes, traveling mechanisms, electric power devices, etc., can solve the problem of low utilization rate of hoisting battery swapping space, and achieve good rigidity, overall height reduction, and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

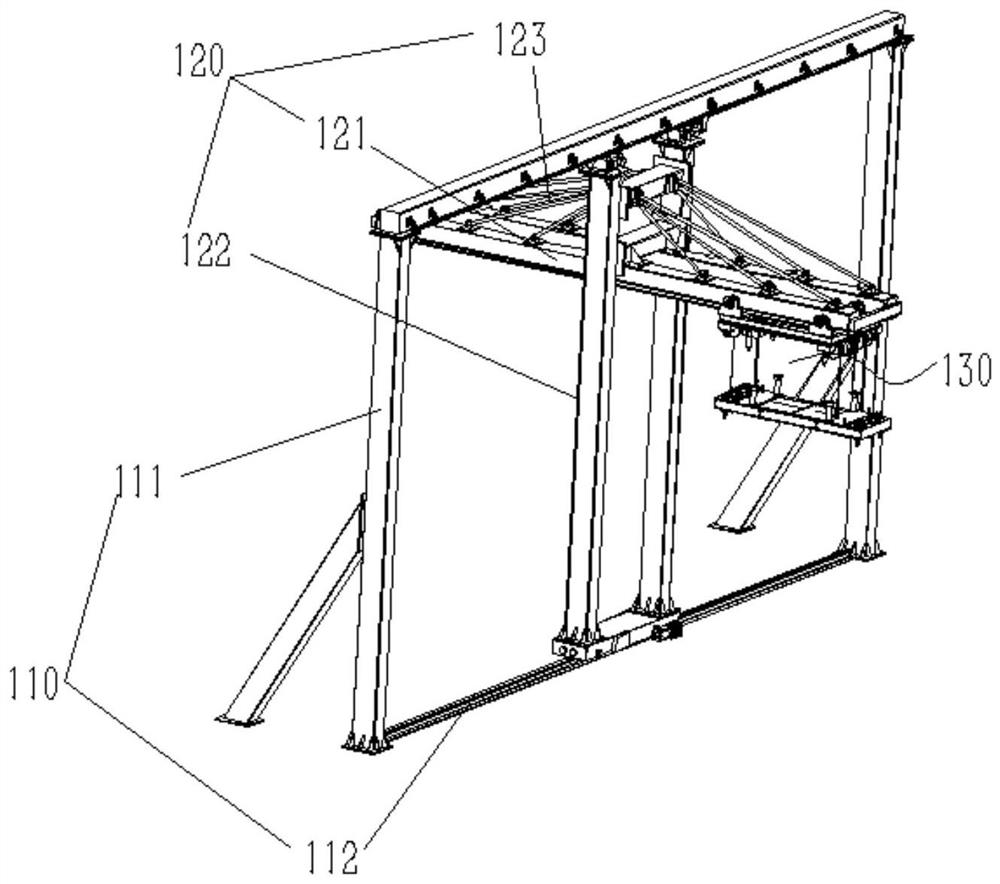

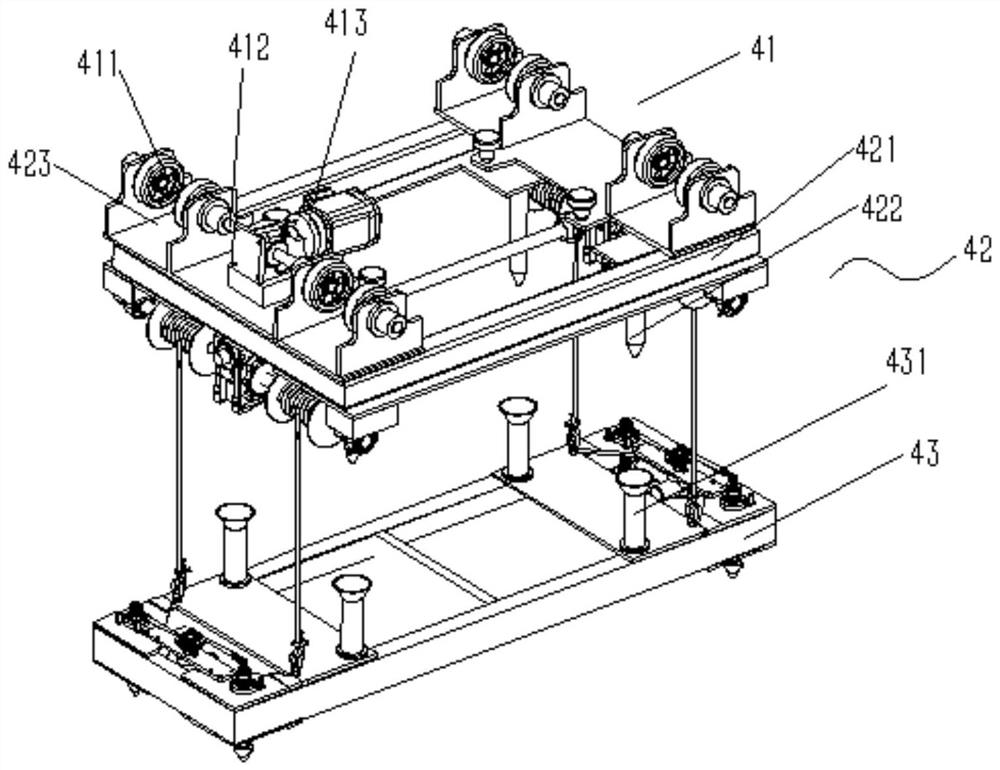

[0024] As mentioned in the background technology, for pure electric heavy-duty vehicle top-mounted battery replacement, the current cantilever beam top-mounted structure usually uses a battery grabbing mechanism arranged on the cantilever beam to remove the exhausted battery on the vehicle to be replaced. Grab the battery box from above, hoist and rotate the power-depleted battery pack at a certain angle and put it into the battery storage area, or grab the charged battery box from above the battery storage area, hoist the charged battery box at a certain angle and place it on the vehicle to be replaced . With the cantilever beam top hoisting structure, the grabbing mechanism needs to lift the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com