3D printing raw material based on PLA reclaimed material, 3D printing material and preparation method thereof

A technology of 3D printing and recycled materials, applied in the field of 3D printing, can solve the problems of difficult secondary utilization of PLA waste, achieve the effects of saving social and natural resources, simple and easy preparation methods, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

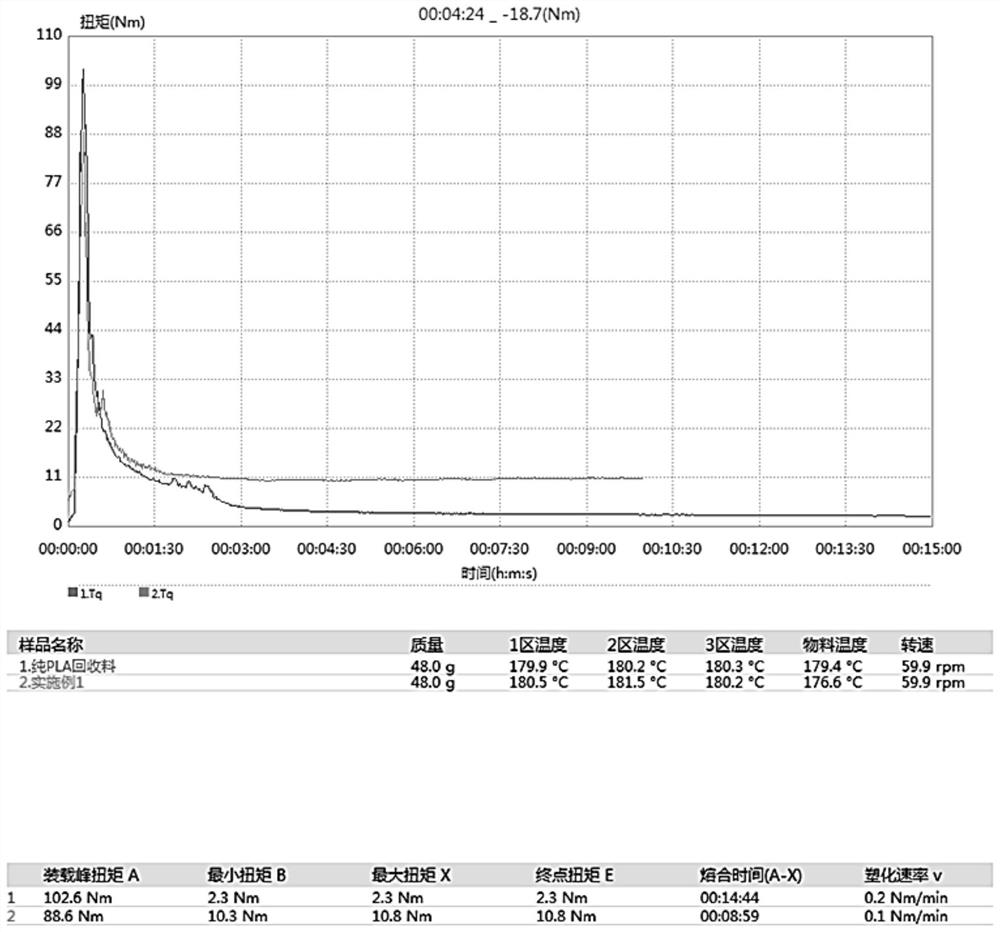

Embodiment 1

[0048]Take 85 parts of pre-dried PLA recycled material, 0.5 part of plasticizer PCL, 0.5 part of crosslinking agent BPO, 5 parts of chain extender ADR, 3 parts of toughening agent PLA-TPU, lubricant stearic acid 1840 and polyethylene wax 0.25 parts each of 3316, 0.25 parts each of antioxidants 1010 and 168, 5 parts of talc powder SD-4000 treated with silane coupling agent, put into a high-speed mixer and mix for 15 minutes, after mixing evenly, melt and blend through a twin-screw extruder Extruded, water-cooled and pelletized, the working temperature is 175°C, and the working pressure is 4.2MPa. The obtained blended modified particles were dried in a vacuum oven at 65°C for 4 hours, and the moisture content was measured to be less than 0.2%, taken out, poured into the hopper of a single-screw extruder, and melted and extruded to form filaments with a diameter of 1.75mm , the working temperature is 210°C, the working pressure is 3.8MPa, the filament is wound up with a special 3...

Embodiment 2

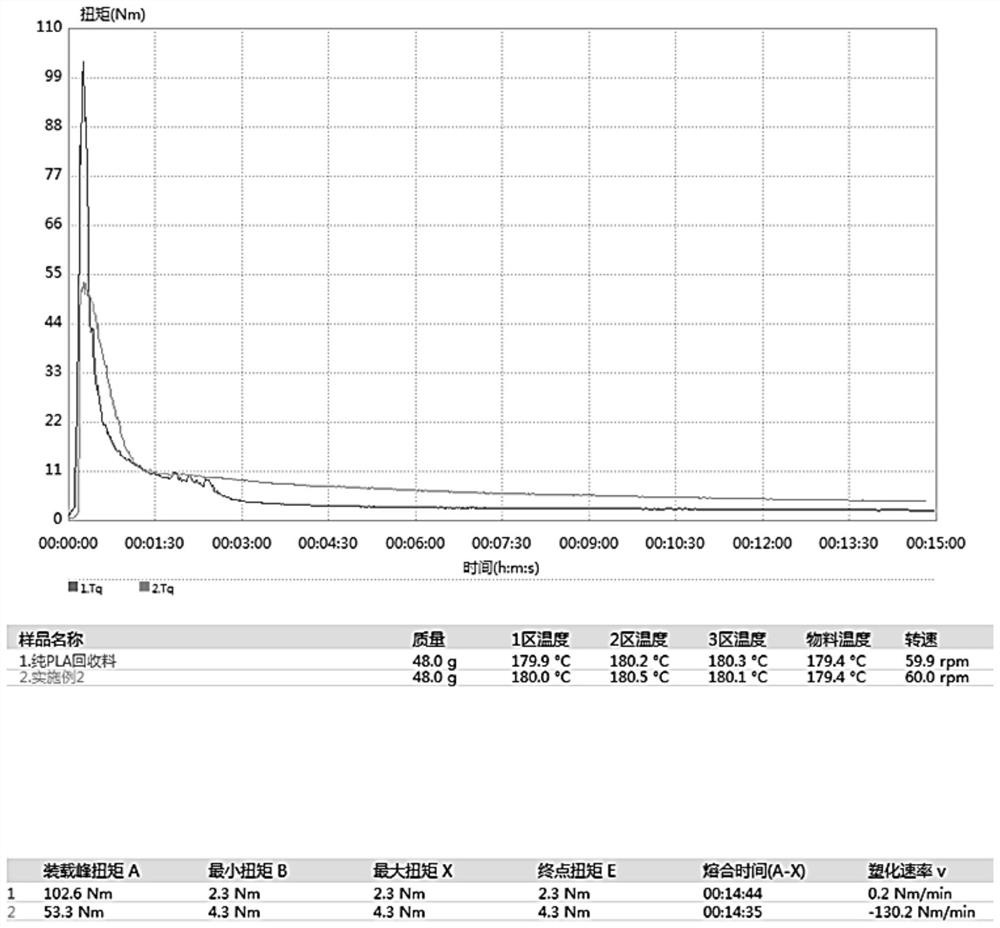

[0051] Take 90 parts of pre-dried PLA recycled material, 1 part of plasticizer ATBC, 0.5 part of crosslinking agent DCP, 2 parts of chain extender HDI, 2.5 parts of toughening agent FM40, lubricant silicone powder KJ-B118 and polyethylene wax 0.25 parts of 3316, 0.25 parts of antioxidant 1010 and AS4500, 0.25 parts of calcium carbonate HX-8164 treated with silane coupling agent, put into high-speed mixer and mix for 15 minutes, after mixing evenly, melt and blend through twin-screw extruder Extruded, water-cooled and pelletized, the working temperature is about 180°C, and the working pressure is 3.25MPa. The obtained blended modified particles were dried in a vacuum oven at 65°C for 4 hours, and the moisture content was measured to be less than 0.2%, taken out, poured into the hopper of a single-screw extruder, and melted and extruded to form filaments with a diameter of 1.75mm , the working temperature is 210°C, the working pressure is 3.0MPa, the filament is wound up with a ...

Embodiment 3

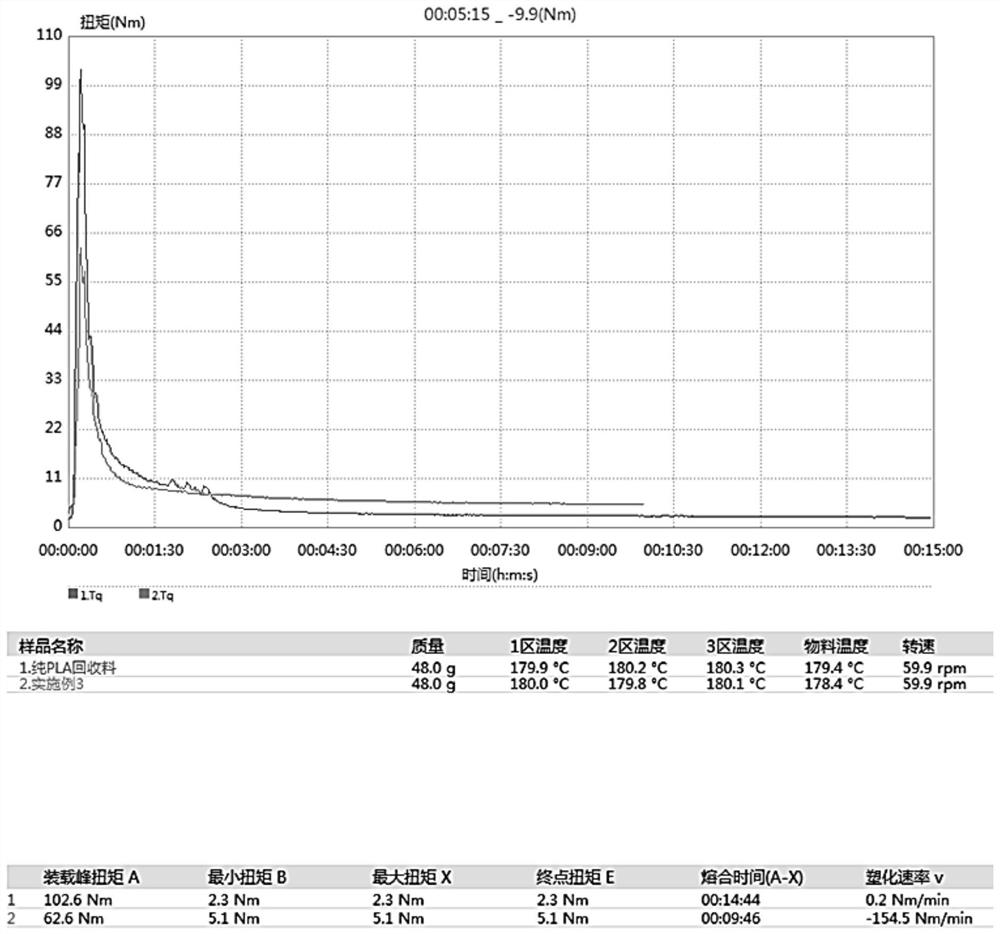

[0054] Take 85 parts of pre-dried PLA recycled materials, 0.5 parts of plasticizer PPG, 0.2 parts of crosslinking agent BIPB, 4.5 parts of chain extender phosphite, 3 parts of toughening agent POE, lubricant silicone powder KJ-B118 and paraffin wax 0.5 parts of 56# each, 0.4 parts of each of antioxidant 168 and AS4500, 5 parts of TH106 wollastonite treated with silane coupling agent, put into a high-speed mixer and mix for 15 minutes. Mixed extrusion, water-cooled pelletizing, working temperature is 170°C, working pressure is 2.8MPa. The obtained blended modified particles were dried in a vacuum oven at 65°C for 4 hours, and the moisture content was measured to be less than 0.2%, taken out, poured into the hopper of a single-screw extruder, and melted and extruded to form filaments with a diameter of 1.75mm , the working temperature is 220°C, the working pressure is 2.5MP, the filament is wound up with a special 3D printing reel, and the FDM 3D printing test is carried out on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com