High-entropy nitride coating for aviation bearing surface protection and preparation method thereof

A technology of bearing surface and nitride, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of single element and inability to fully exert the synergistic effect of multiple elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A high-entropy nitride coating for aircraft bearing surface protection, the high-entropy nitride coating is (CrAlTiNbV)N x , x=0.3; the elements contained in it are calculated by atomic percentage: Cr is 30 at. %, Al is 15 at. %, Ti is 3 at. %, Nb is 7 at. %, V is 15 at. %, N 30 at. %.

[0036] Its preparation method:

[0037] ⑴Use absolute ethanol and acetone to ultrasonically clean the steel sample for 15 minutes, dry the sample and put it in a vacuum chamber for vacuuming;

[0038] ⑵When the vacuum degree is lower than 3×10 -3 The coating work was started at Pa; argon gas was introduced, and the argon content was fixed at 18 sccm during the preparation process, and the internal pressure of the vacuum chamber was 0.24 Pa. A pulse bias power supply was added to the sample, and at a bias voltage of -450 V Use argon plasma to pre-sputter and clean the sample for 20-30 minutes to remove the oxide layer and other impurities on the surface;

[0039] (3) Keep ...

Embodiment 2

[0042] Example 2 A high-entropy nitride coating for aircraft bearing surface protection, the high-entropy nitride coating is (CrAlTiNbV)N x , x=0.35; the elements contained in it are calculated by atomic percentage: Cr is 20 at. %, Al is 15 at. %, Ti is 10 at. %, Nb is 10 at. %, V is 10 at. %, N is 35 at. %.

[0043] Its preparation method::

[0044] ⑴Use absolute ethanol and acetone to ultrasonically clean the steel sample for 15 minutes, dry the sample and put it in a vacuum chamber for vacuuming;

[0045] ⑵When the vacuum degree is lower than 3×10 -3 The coating work was started at Pa; argon gas was introduced, and the argon content was fixed at 18 sccm during the preparation process, and the internal pressure of the vacuum chamber was 0.24 Pa. A pulse bias power supply was added to the sample, and at a bias voltage of -450 V Use argon plasma to pre-sputter and clean the sample for 20-30 minutes to remove the oxide layer and other impurities on the surface;

[0046] (3...

Embodiment 3

[0049] Example 3 A high-entropy nitride coating for aircraft bearing surface protection, the high-entropy nitride coating is (CrAlTiNbV)N x , x=0.45; the elements contained in it are calculated by atomic percentage: Cr is 15 at. %, Al is 10 at. %, Ti is 10 at. %, Nb is 5 at. %, V is 15 at. %, N is 45 at. %.

[0050] Its preparation method:

[0051] ⑴Use absolute ethanol and acetone to ultrasonically clean the steel sample for 15 minutes, dry the sample and put it in a vacuum chamber for vacuuming;

[0052] ⑵When the vacuum degree is lower than 3×10 -3 The coating work was started at Pa; argon gas was introduced, and the argon content was fixed at 18 sccm during the preparation process, and the internal pressure of the vacuum chamber was 0.24 Pa. A pulse bias power supply was added to the sample, and at a bias voltage of -450 V Use argon plasma to pre-sputter and clean the sample for 20-30 minutes to remove the oxide layer and other impurities on the surface;

[0053] (3) ...

PUM

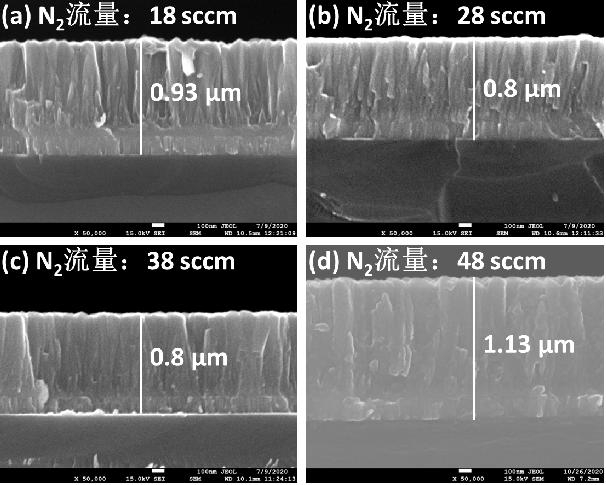

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com