Watering paraffin control method for prefabricated small oil pipe in rodless lifting oil well shaft

An in-well, small tubing technology, applied in wellbore/well components, earthwork drilling, isolation devices, etc., can solve the problems of operation and maintenance costs, insufficient crude oil production in the formation with operating strength, oil well wax deposition, and small displacement, etc. Achieve the effect of less wellhead structure modification, increased temperature and flow rate, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

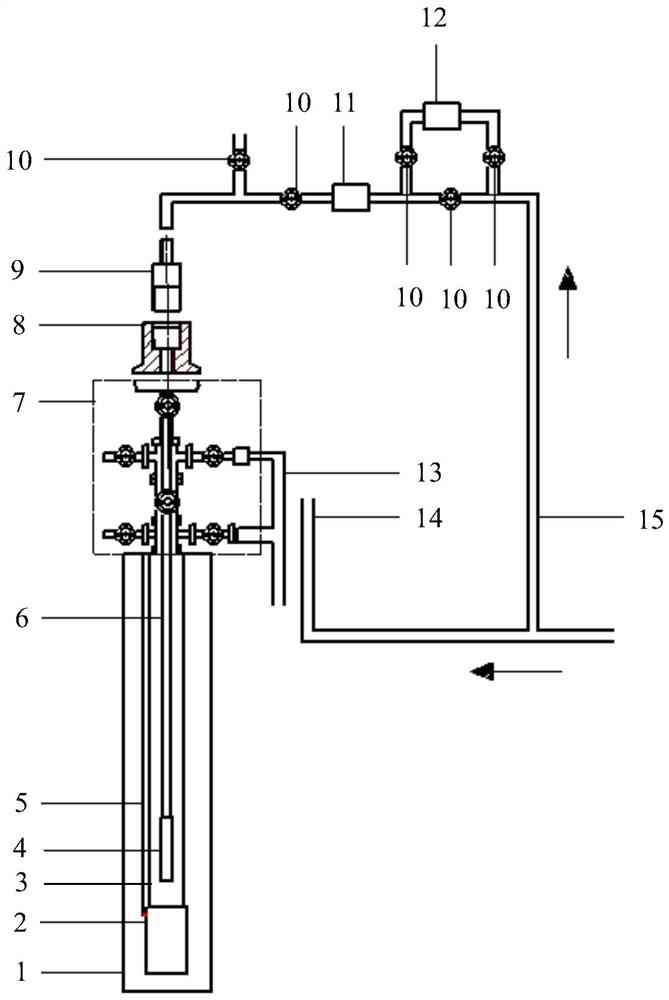

[0016] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. The present invention is realized by the following devices: it consists of casing 1, lifting equipment 2, tubing 3, check valve 4, cable 5, small-diameter tubing 6, Christmas tree 7, wellhead sealing suspension device 8, and tubing variable buckle 9 , valve 10, measuring instrument 11, booster pump 12, oil pipeline 13, water mixing pipeline 14 and water injection pipeline 15;

[0017] Using the above device, a prefabricated small oil pipe mixed with water and wax prevention method in the wellbore of a rodless lift oil well, the specific steps are as follows:

[0018] a. First connect the lifting equipment 2, the cable 5, and the tubing 3 from bottom to top and lower them into the well;

[0019] b. Sitting on the Christmas tree 7 at the wellhead, lower the check valve 4 and the small-diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com