Ultra-fine and ultra-thick paint film enameled wire and manufacturing method thereof

A production method and ultra-fine technology, applied in the direction of cable/conductor manufacturing, conductor, conductor/cable insulation, etc., can solve the problem of frequent disconnection in the production process, difficulty in controlling the surface quality of the finished wire and the concentricity of the paint film, and production efficiency. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] An ultra-fine and ultra-thick enameled wire of the present embodiment includes a copper rod 60 and an insulating varnish layer;

[0046] The copper rod 60 is an annealed low-oxygen copper rod 60 with an oxygen content of 180-230 ppm, and the diameter of the copper rod 60 is φ0.03 mm;

[0047] The insulating varnish layer is evenly wrapped around the copper rod 60 ; the thickness of the insulating varnish layer is 0.015-0.025 mm, preferably 0.015 mm in this embodiment.

[0048] More specifically, the insulating paint layer is a polyurethane paint layer. The polyurethane paint is grade 180 polyurethane paint, and its viscosity during painting is 20-25 mp.s, preferably 20 mp.s in this embodiment.

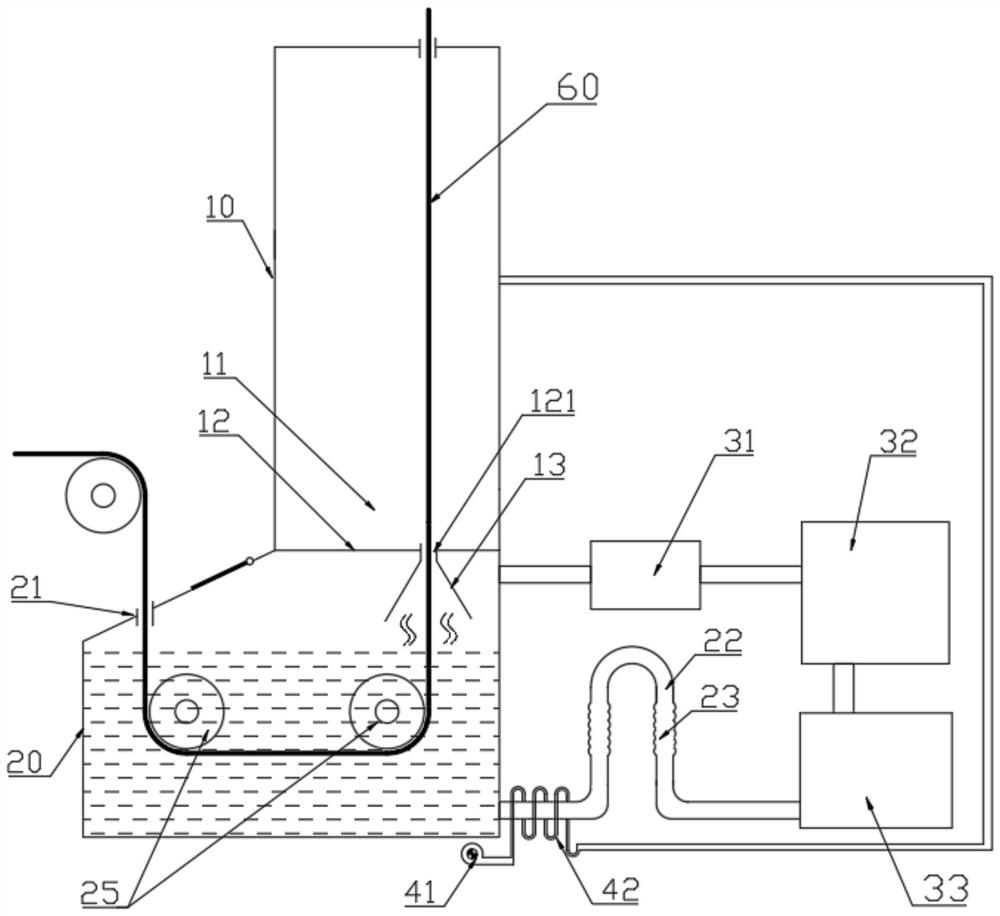

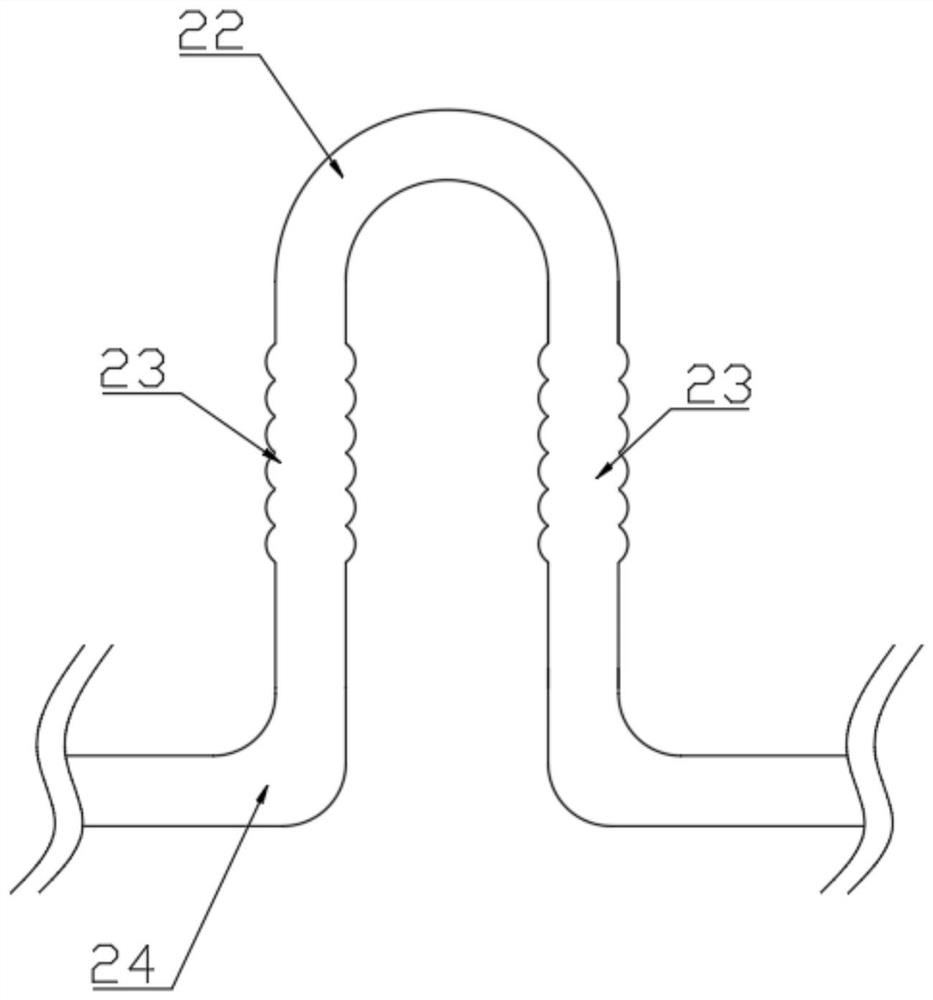

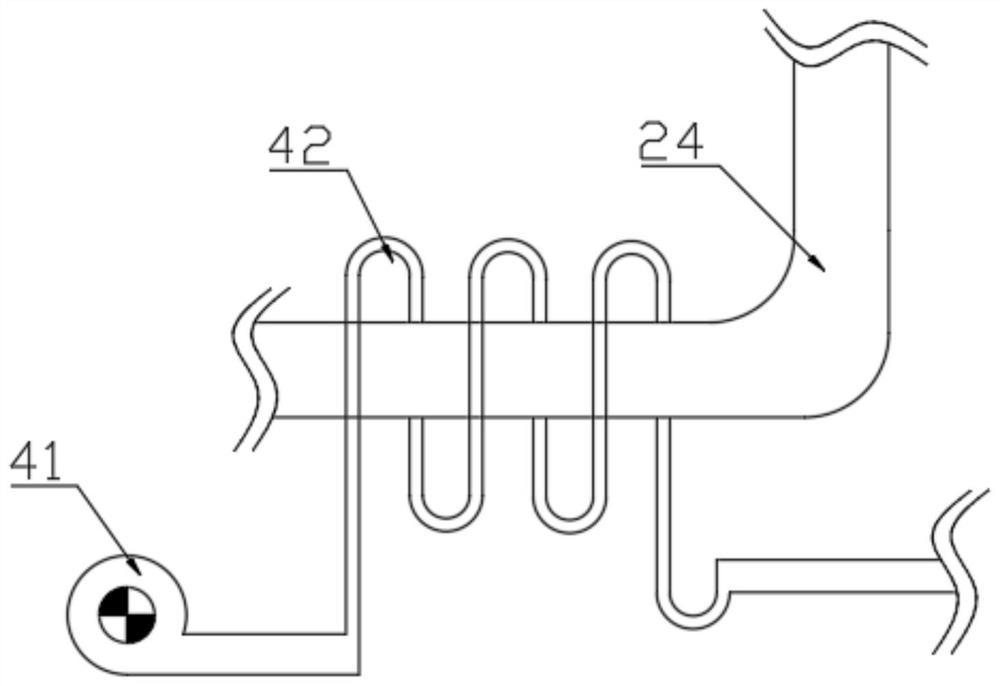

[0049] see Figure 1 to Figure 5 , the present embodiment also provides a method for manufacturing an ultra-fine ultra-thick enameled wire, comprising the following steps:

[0050] Step 1. Wire drawing: select an annealed low-oxygen copper rod 60 of φ2.6mm with an oxygen conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com