Mask manufacturing method based on fused deposition in-situ 3D printing technology

A fused deposition and 3D printing technology, used in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of poor sealing performance of masks and poor comfort of masks, and achieve good sealing performance, shortened processing cycle, and good protection. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

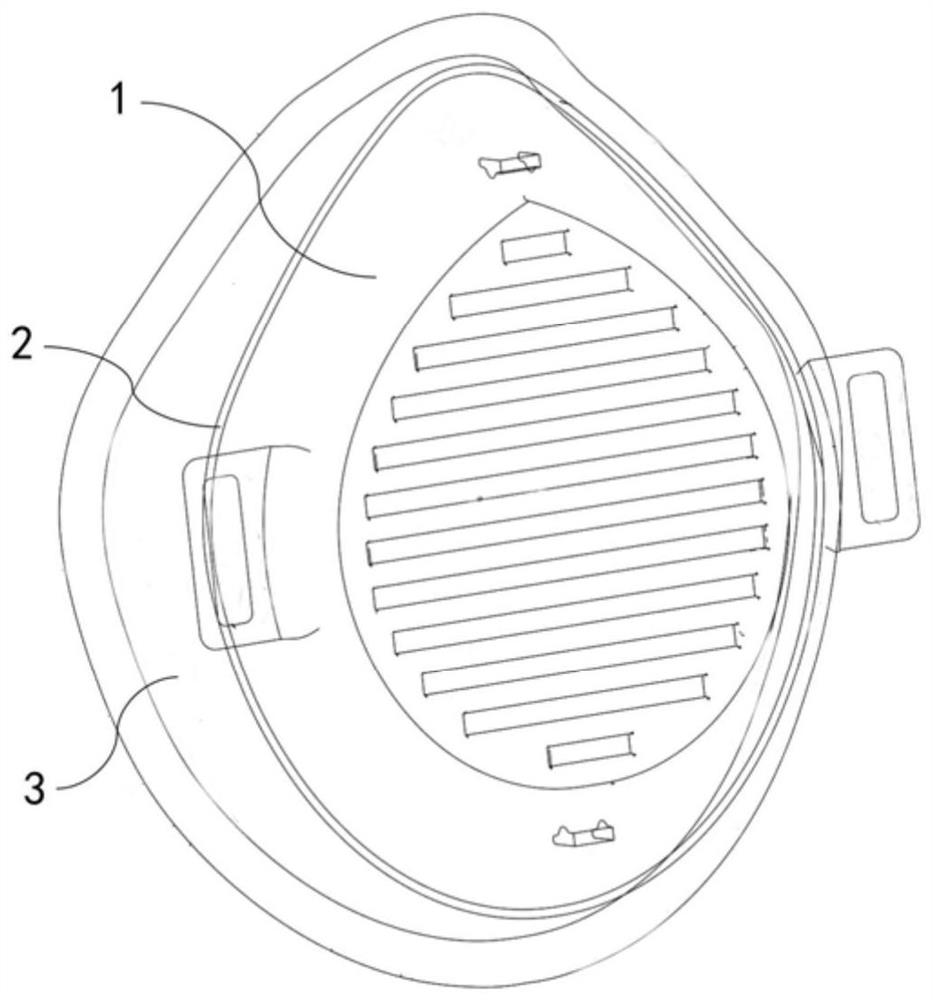

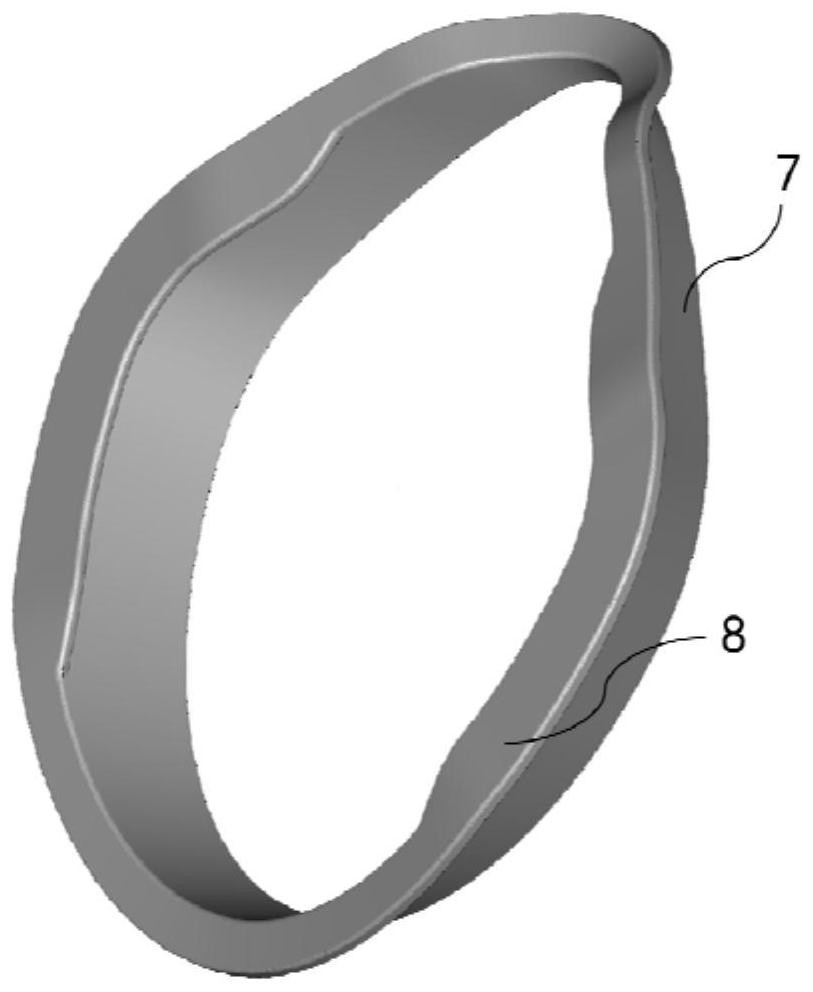

[0021] figure 1 Shown is a schematic diagram of a replaceable filter mask made based on fused deposition modeling in-situ 3D printing technology, including the main part 1 of the mask and the face fitting part 3 of the mask.

[0022] Preferably, figure 2 Shown is the concrete structure of the main body part 1 of mouth mask. First, use Solidworks software to design the CAD three-dimensional model of the main part of the mask, determine the parameters of the position, angle and size of each component, including the vent 4 used for breathing, and equip a fixed structure 5 to install the filter to play a protective filtering role. There is an ear-hook connection structure 6, which can be replaced with a head-mounted strap according to the user's wearing habits. This part uses the mode of injection mold processing to manufacture in ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com