Coal mine underground solid-liquid separation and purification device

A solid-liquid separation and purification device technology, applied in separation methods, sedimentation separation, filtration separation, etc., can solve problems such as hidden dangers in mines, high manpower and financial resources, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

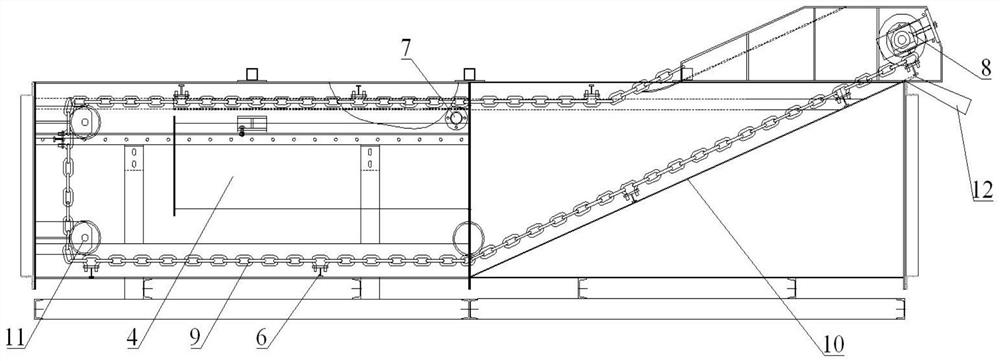

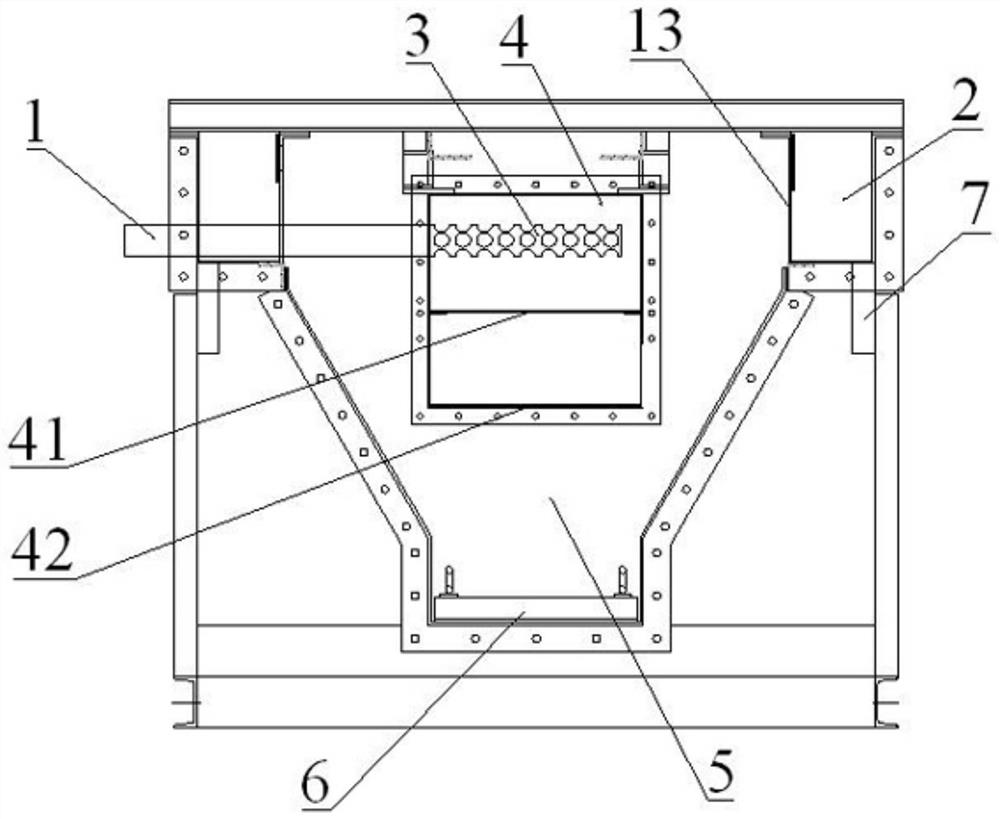

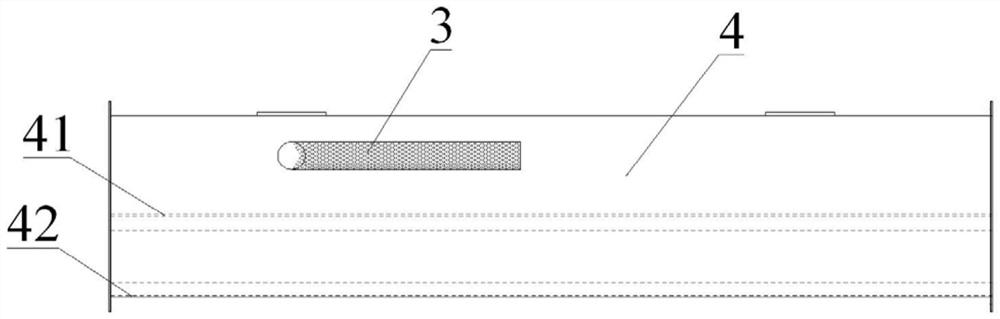

[0022] see figure 1 with figure 2 , a solid-liquid separation and purification device for underground coal mines provided by the present invention is composed of a collection pipeline 1, a diffuser 4, a settling box 5, and a discharge mechanism. The other end of the pipeline 1 communicates with the side wall of the diffuser 4, and through holes are evenly distributed on the side wall of the outlet section 3 of the collection pipeline extending into the diffuser 4. The collection pipeline 1 is arranged horizontally, and the coal gangue water mixture passes through the The pores change the direction of flow, depositing downward.

[0023] see image 3 , the diffuser 4 is arranged in the middle and upper part of the sedimentation tank 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com