Hard alloy composite side tooth for high-pressure roller mill and preparation method of hard alloy composite side tooth

A high-pressure roller mill and cemented carbide technology, which is applied in grain processing and other fields, can solve the problems of low overall efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

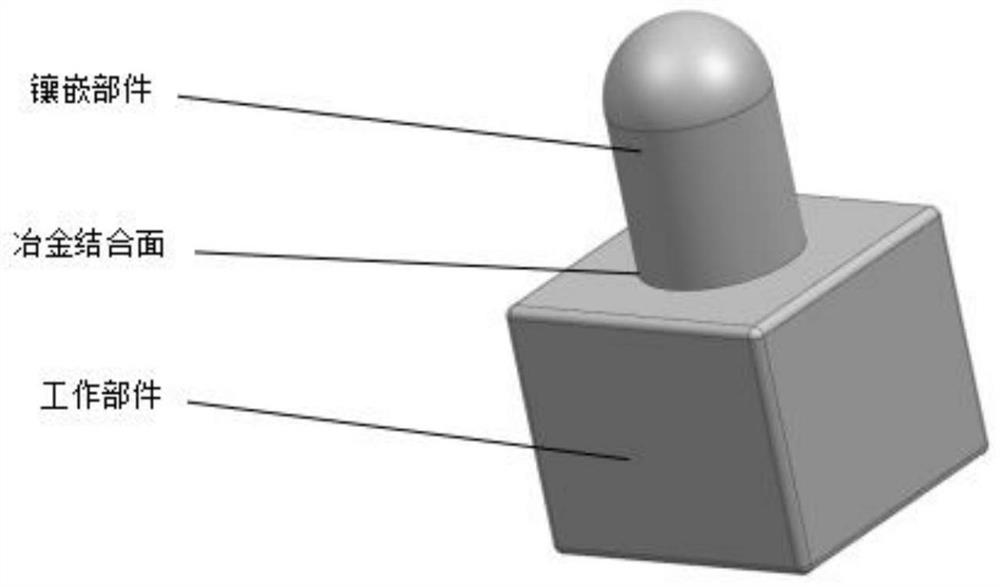

[0026] A cemented carbide composite side tooth, the product is used for anti-abrasion on the edge of the roll surface of a high-pressure roller mill. The weight percentage of the alloy formula of this composition: ①Working parts: Co powder 15%, Fsss particle size 2-3μm; WC85%, Fsss Particle size 3 ~ 4μm. ② Mosaic parts: Co powder 11%, Fsss particle size 2-3μm; WC: 89%, Fsss particle size 3-4μm. The shape of the product is as figure 1 shown.

[0027] The preparation method of the above-mentioned cemented carbide composite side teeth: ① working parts: take the above-mentioned raw materials in proportion, with a total weight of 600kg, put them into a 600L tiltable ball mill, use alcohol as the wet grinding medium, and the ball-to-material ratio is 4.3:1, The liquid-solid ratio is 300ml / kg, and the paraffin molding agent is added according to 2% of the total weight of the raw materials. The ball milling time is 36 hours. After the wet-milled slurry is spray-dried and pressed, it...

Embodiment 2

[0030] A cemented carbide composite edge tooth, which is used for anti-abrasion on the edge of the roll surface of a high-pressure roller mill. The weight percentage of the alloy formula of this composition: ①Working parts: Co powder: 14.5%, Fsss particle size 2-3μm, Cr 3 C 4 content of 0.5%, Fsss particle size 1 ~ 2μm, WC: 85%, Fsss particle size 2 ~ 3μm; ② mosaic parts: Co powder: 18%, Fsss particle size 2 ~ 3μm, WC: 80%, Fsss particle size 3 ~ 4μm ;Product shape such as figure 1 shown.

[0031] The preparation method of the above-mentioned cemented carbide composite side teeth: ① Working parts: Take the above-mentioned raw materials in proportion, with a total weight of 600kg, put them into a 600L tiltable ball mill, use alcohol as the wet grinding medium, and the ball-to-material ratio is 4.5:1. The solid ratio is 330ml / kg, and the paraffin molding agent is added according to 2% of the total weight of the raw materials. The ball milling time is selected to be 37h. After ...

Embodiment 3

[0034] A cemented carbide composite edge tooth, which is used for anti-abrasion on the edge of the roll surface of a high-pressure roller mill. The weight percentage of the alloy formula of this composition: ①Working parts: Co powder 18%, Fsss particle size 2-3μm; WC82%, Fsss particle size 2~3μm. ② Mosaic parts: weight ratio TiC35%, Fe 59%, Mo 2%, Cr2%, its hardness is 84. The shape of the product is as figure 1 shown.

[0035]The preparation method of the above-mentioned cemented carbide composite side teeth: ① working parts: take the above-mentioned raw materials in proportion, with a total weight of 600kg, put them into a 600L tiltable ball mill, use alcohol as the wet grinding medium, and the ball-to-material ratio is 5.5:1, The liquid-solid ratio is 300ml / kg, and the paraffin molding agent is added according to 2% of the total weight of the raw materials. The ball milling time is 38 hours. After the wet-milled slurry is spray-dried and pressed, it is sintered under a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com