Noise reduction type recovery device for plastic waste based on PBAT raw materials

A recycling equipment and noise-reducing technology, applied in the field of noise-reducing recycling equipment, can solve problems such as staff injury, unfavorable plastic waste crushing work, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

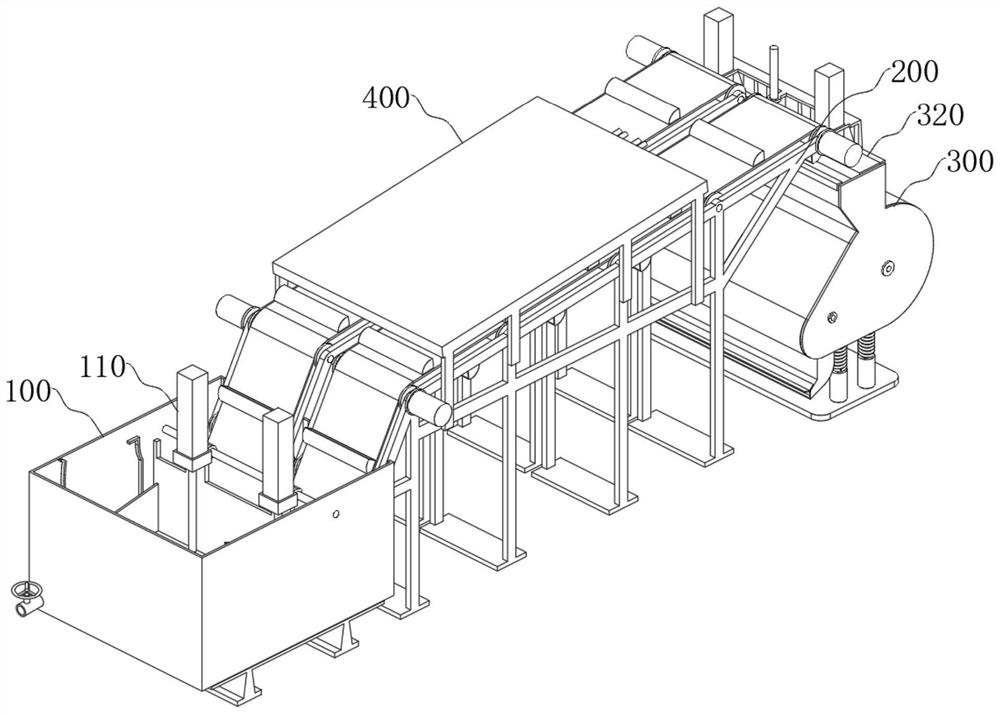

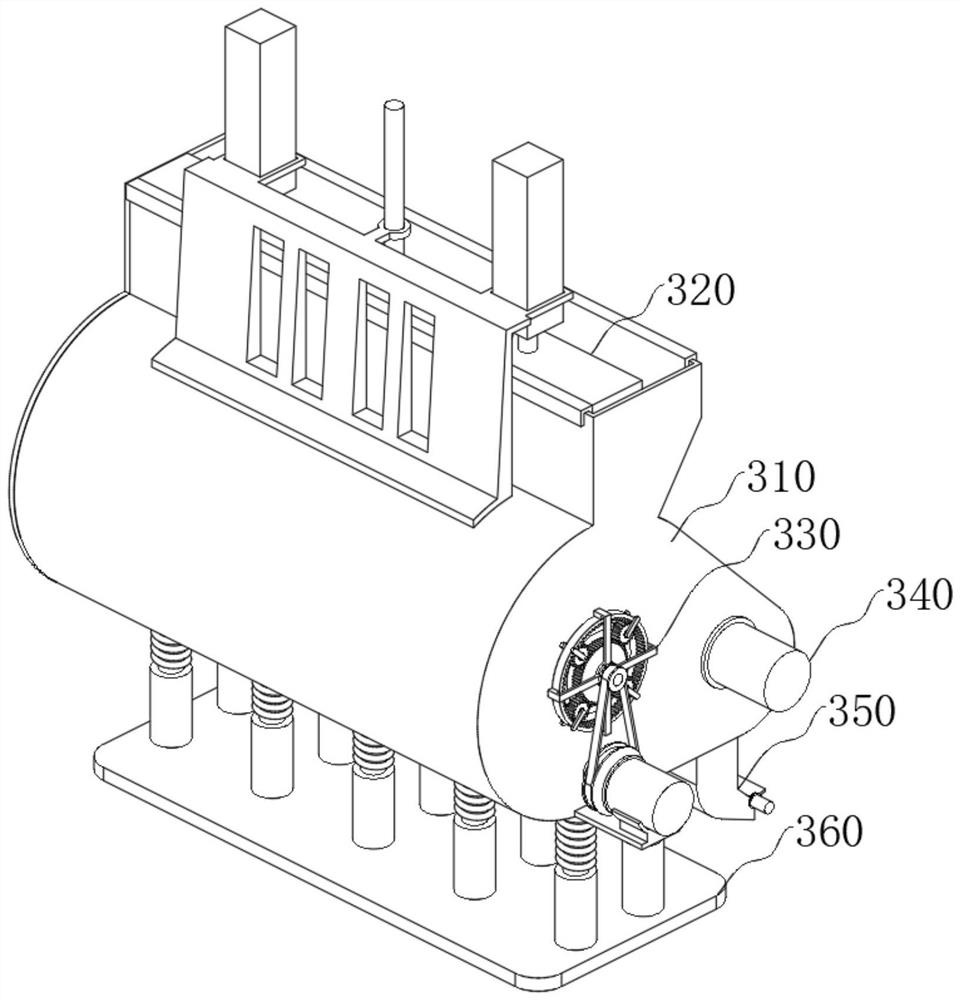

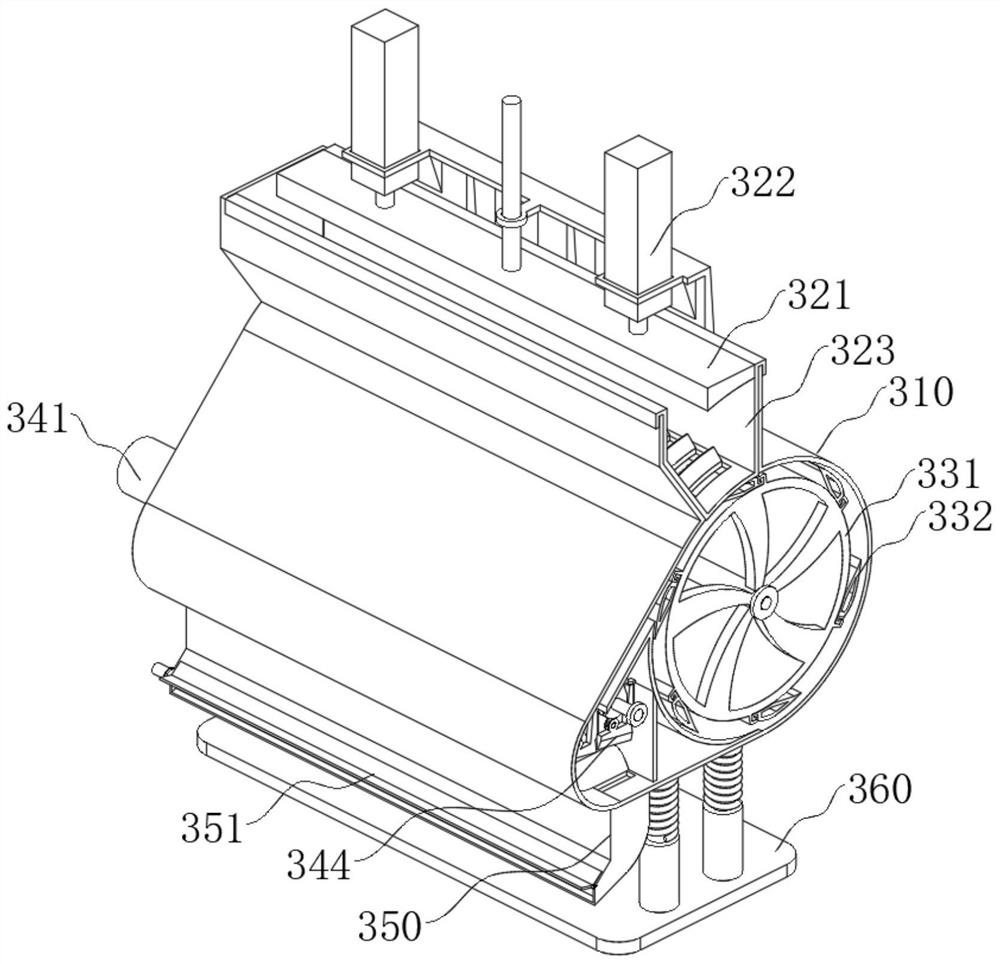

[0063] see Figure 1 to Figure 25 As shown, the present invention provides a noise-reducing recycling equipment for plastic waste products based on PBAT raw materials, including a cleaning stock tank 100, a number of transport racks 200 placed side by side, a heating cover 400 for heating and softening plastics, and an electric heating cover 400. A heating pipe 410 and a cutting machine 300 for slicing the softened plastic. This recycling equipment mainly cleans and decontaminates the recycled plastic waste by cleaning the material preparation pool 100, and then transports them through the transport rack 200, and bakes them to a softened state through the electric heating tube 410 in the heating cover 400 above it, and then falls into the cutting machine. The material is sliced and discharged in the feeder 300, thereby greatly eliminating the noise generated by head-to-head crushing of plastics.

[0064] In this embodiment, the material cutting machine 300 includes a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com