Polyolefin film with layered structure and application thereof

A technology of polyolefin film and layered structure, which is applied in the field of agricultural film, can solve the problems of limited anti-fog performance, lack of anti-fog ability, and only 3 to 4 months, so as to promote morning market, improve crop quality, and transparent The effect of low light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

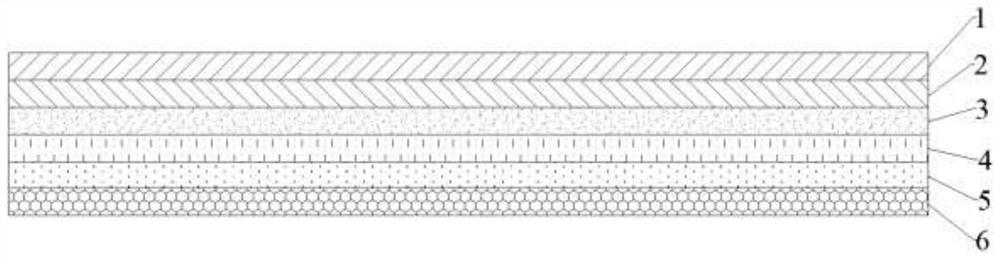

[0037] refer to figure 1 , a polyolefin film with a layered structure, including a coating 1, an outer film 2, a sub-outer film 3, a middle film 4, a sub-inner film 5 and an inner film 6 from outside to inside. By mass percentage:

[0038] The raw material composition of the outer film 2 includes: 10% PE, 86% metallocene, 3.9% 944 polymerized hindered amine light stabilizer, 0.05% antioxidant 1010, 0.05% antioxidant 168.

[0039] The raw material composition of the secondary outer layer film 3 includes: 10% PE, 85% metallocene, 4.9% 944 polymerized hindered amine light stabilizer, 0.05% antioxidant 1010, 0.05% antioxidant 168.

[0040] The raw material composition of the middle film 4 includes: 30% PE, 55% metallocene, 10% brucite, 4.9% 944 polymeric hindered amine light stabilizer, 0.05% antioxidant 1010, 0.05% antioxidant 168.

[0041] The raw material composition of the sub-inner layer film 5 includes: 20% PE, 75% metallocene, 4.9% 944 polymerized hindered amine light sta...

no. 2 example

[0045] refer to figure 1 , a polyolefin film with a layered structure, including a coating 1, an outer film 2, a sub-outer film 3, a middle film 4, a sub-inner film 5 and an inner film 6 from outside to inside. By mass percentage:

[0046] The raw material composition of the outer film 2 includes: 8% PE, 88% metallocene, 3.86% 944 polymerized hindered amine light stabilizer, 0.07% antioxidant 1010, and 0.07% antioxidant 168.

[0047] The raw material composition of the secondary outer film 3 includes: 7.3% PE, 87.5% metallocene, 5.0% 944 polymerized hindered amine light stabilizer, 0.2% antioxidant 1010, 0.3% antioxidant 168.

[0048] The raw material composition of the middle film 4 includes: 25% PE, 60% metallocene, 10% brucite, 4.85% 944 polymerized hindered amine light stabilizer, 0.1% antioxidant 1010, 0.05% antioxidant 168.

[0049] The raw material composition of the sub-inner layer film 5 includes: 15% PE, 80% metallocene, 4.8% 944 polymerized hindered amine light st...

no. 3 example

[0053] refer to figure 1 , a polyolefin film with a layered structure, including a coating 1, an outer film 2, a sub-outer film 3, a middle film 4, a sub-inner film 5 and an inner film 6 from outside to inside. By mass percentage:

[0054] The raw material composition of the outer film 2 includes: 11% PE, 85% metallocene, 3.9% 944 polymerized hindered amine light stabilizer, 0.05% antioxidant 1010, and 0.05% antioxidant 168.

[0055] The raw material composition of the secondary outer film 3 includes: 11.8% PE, 83% metallocene, 5.0% 944 polymerized hindered amine light stabilizer, 0.1% antioxidant 1010, 0.1% antioxidant 168. .

[0056] The raw material composition of the middle film 4 includes: 35% PE, 50% metallocene, 9.7% brucite, 5.2% 944 polymerized hindered amine light stabilizer, 0.05% antioxidant 1010, 0.05% antioxidant 168.

[0057] The raw material composition of the sub-inner layer film 5 includes: 25% PE, 70% metallocene, 4.95% 944 polymerized hindered amine ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com