Distributed braking system with brake pedal travel simulation and failure manual braking functions

A technology of pedal stroke and human braking, applied in the direction of brake safety system, brake transmission device, brake action activation device, etc., can solve the problems of unreliable failure protection ability and slow brake response, etc., and achieve excellent pedal feel , fast dynamic response and small pressure fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

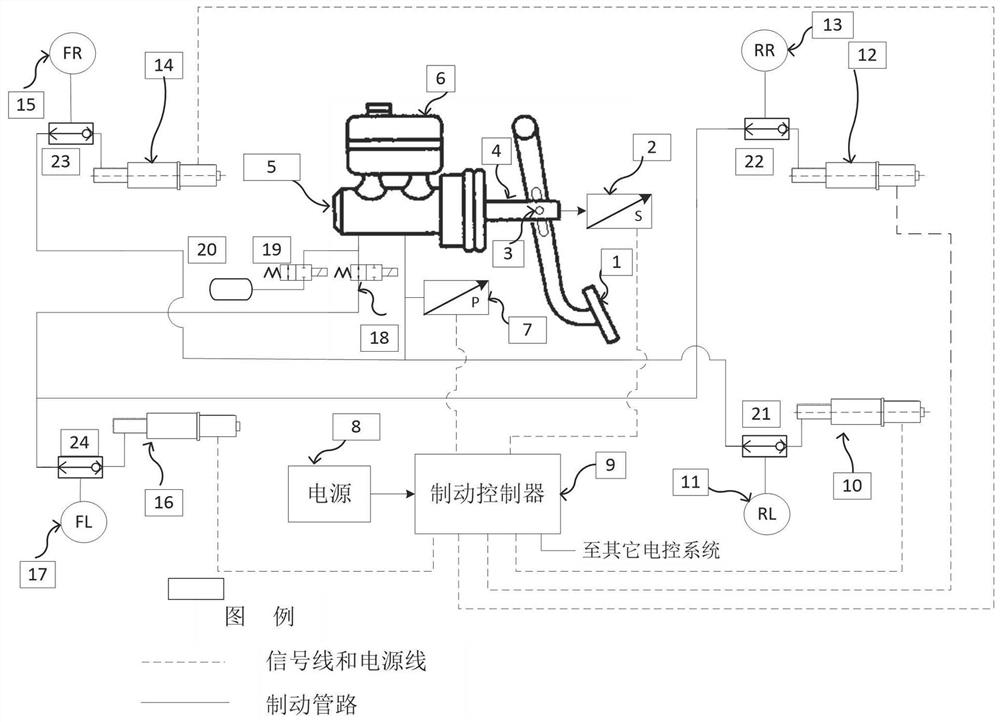

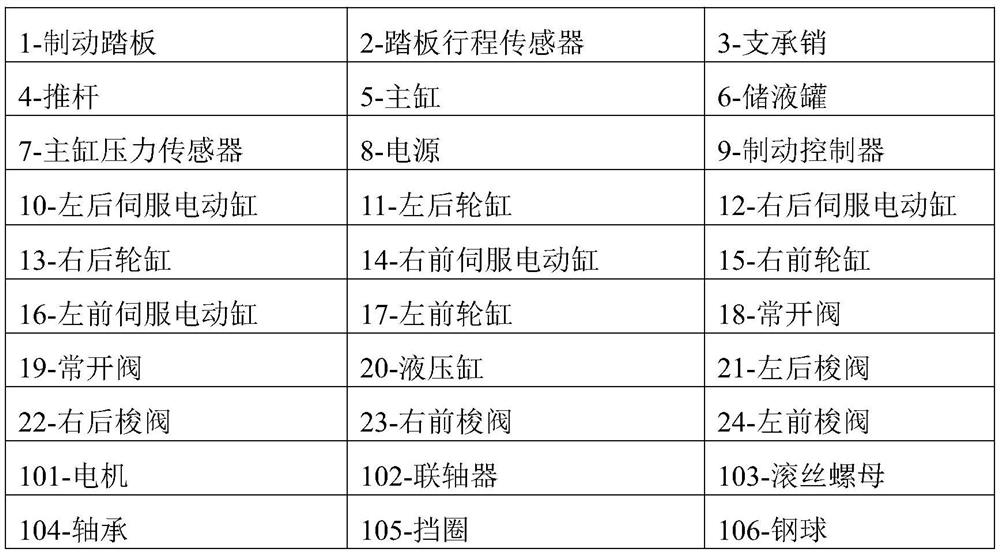

[0043] Such as figure 1 As shown, this embodiment provides a distributed braking system with pedal stroke simulation and failure manpower backup braking function, including a brake pedal 1, a pedal stroke sensor 2, a support pin 3, a push rod 4, a master cylinder 5, Liquid storage tank 6, master cylinder pressure sensor 7, power supply 8, brake controller 9, left rear servo electric cylinder 10, left rear wheel cylinder 11, right rear servo electric cylinder 12, right rear wheel cylinder 13, right front servo electric cylinder 14. Right front wheel cylinder 15, left front servo electric cylinder 16, left front wheel cylinder 17, normally open valve 18, normally closed valve 19, hydraulic cylinder 20, four shuttle valves 21, 22, 23, 24 and brake lines , signal lines and power lines.

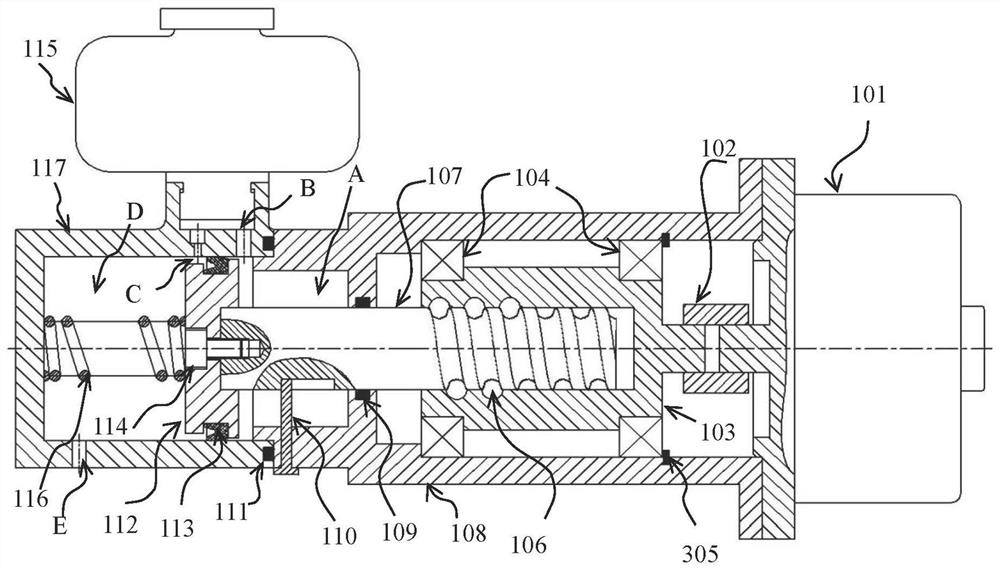

[0044] The master cylinder 5 is a tandem dual-chamber brake master cylinder. The left rear servo electric cylinder 10, the right rear servo electric cylinder 12, the right front servo electric c...

Embodiment 2

[0075] The structure of the distributed braking system in this embodiment is basically the same as in Embodiment 1, the difference is that the four brake actuators in this embodiment are arranged in an H shape, and at this time, the left front shuttle valve 24 and the right front shuttle valve 23 One of their oil inlets is connected to the first brake pipeline through parallel pipelines, and their other oil inlets are respectively connected to the left front servo electric cylinder 16 and the right front servo electric cylinder 14; the left rear shuttle valve 21 and the right One oil inlet of the rear shuttle valve 22 is connected to the second brake pipeline through a pipeline in parallel, and the other oil inlet of each of them is respectively connected to the left rear servo electric cylinder 10 and the right rear servo electric cylinder 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com