High-strength paper tray and preparation technology thereof

A high-strength, pallet technology, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of low impact resistance and supporting strength, and achieve the effects of shortened production time, good impact resistance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

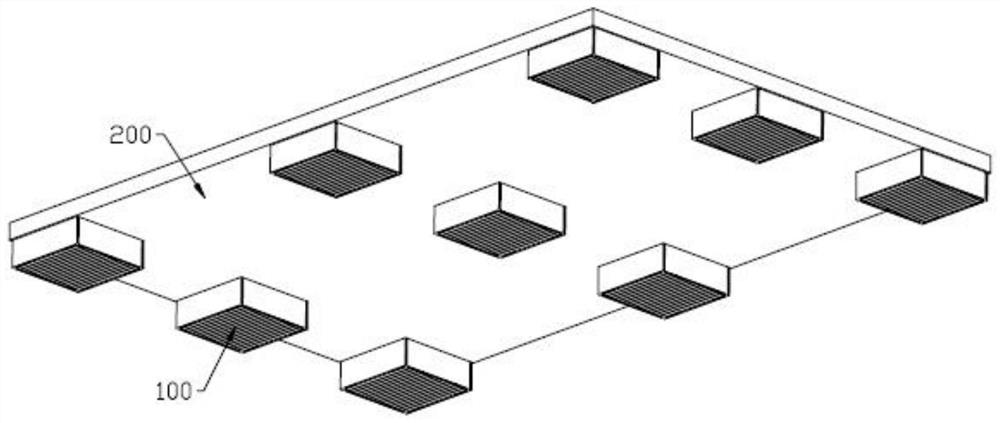

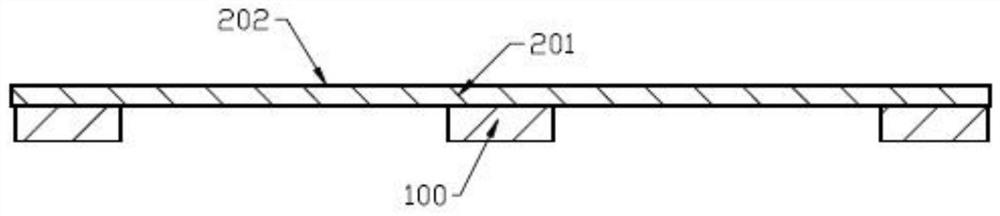

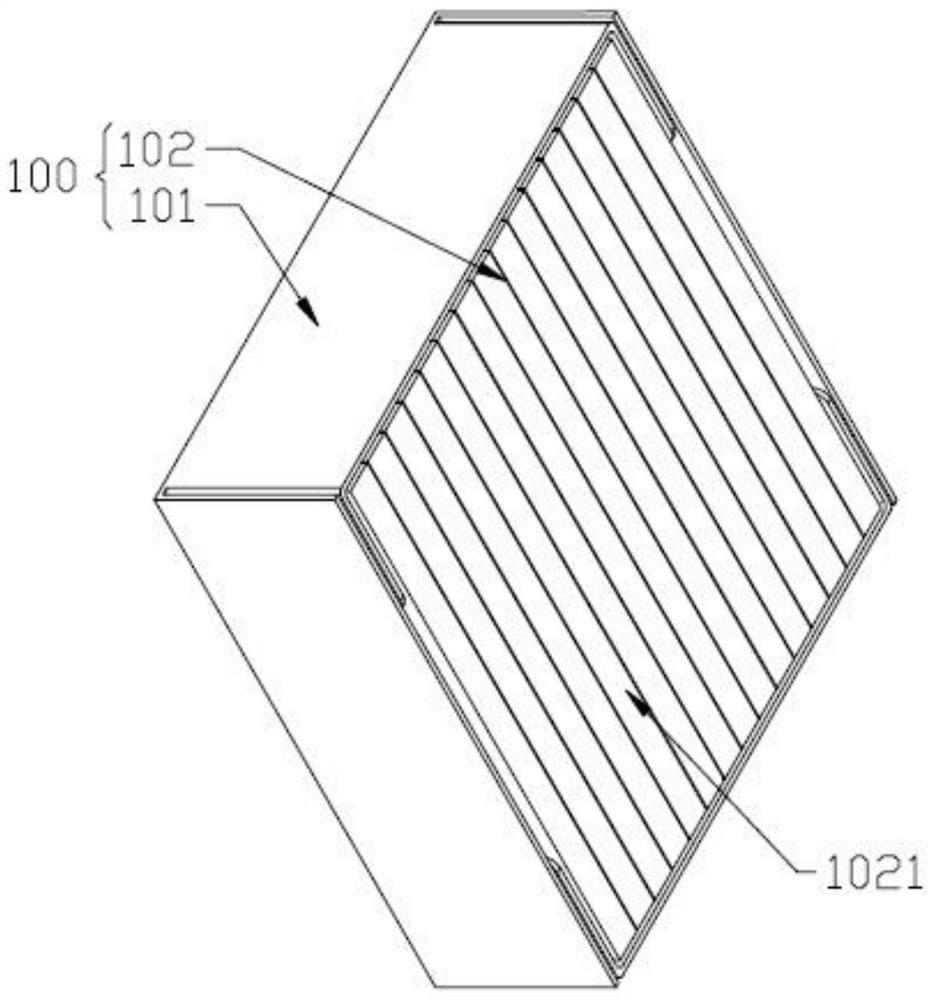

[0034] Such as Figures 1 to 5 As shown, the high-strength paper pallet includes: a pallet 200 and a number of corner columns 100 evenly arranged in a matrix at the bottom of the pallet 200; The layer 201 is used as the main support of the pallet 200 to improve the impact resistance and support strength of the surface of the pallet 200. The protective layer 202 is used to protect the internal support layer 201 from the influence of external water and moisture; the corner post 100 has an open top. The corner post cover 101 of the rectangular parallelepiped cavity structure at the mouth and the inner support plate group 102 fixed inside the corner post cover 101; the corner post cover 101 has a corner post base plate 1011, and a corner post first formed by bending 90° along a set of opposite sides of the corner post b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com