Special material for plastic glass fiber reinforced plastic septic tank and preparation method thereof

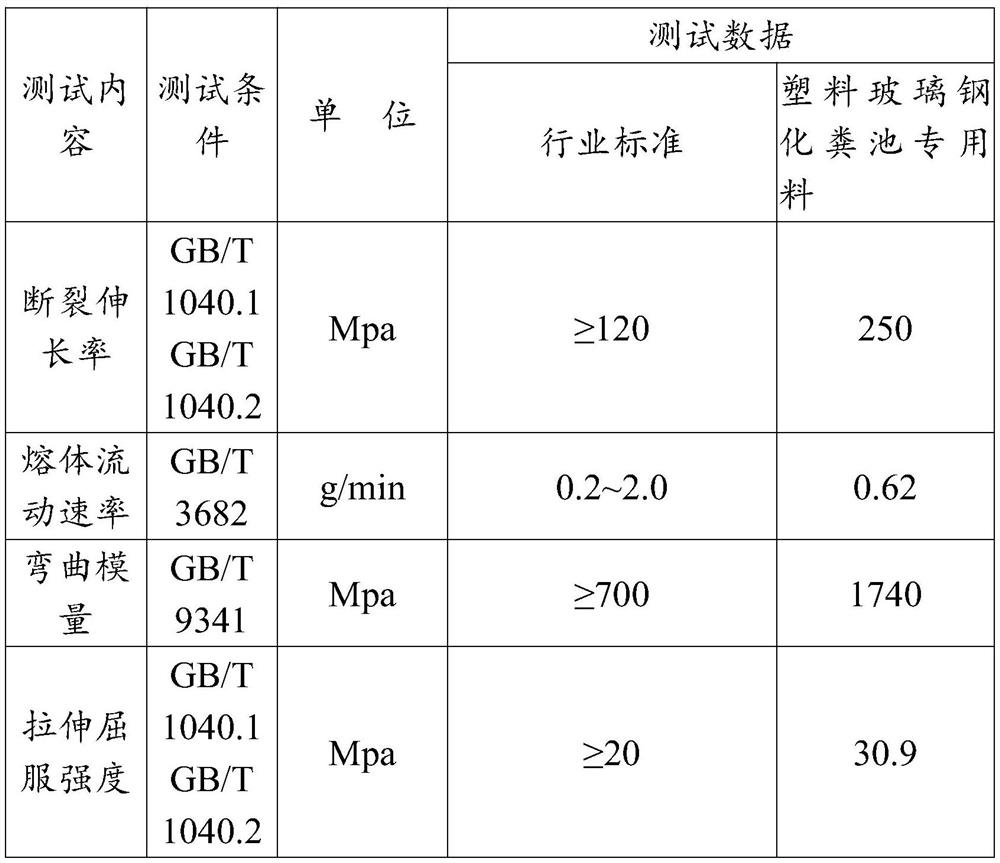

A glass tempering and special material technology, applied in the field of material processing, can solve the problems of easy breakage, low hardness and strength, easy deformation, etc., and achieve the effects of good weather resistance and high temperature resistance, good use safety, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, the present invention provides a special material for plastic glass reinforced plastic septic tanks, including the following raw materials in parts by weight: 40-60 parts of high-density polyethylene, 10-20 parts of acrylonitrile-butadiene-styrene, 5 parts of polyoxymethylene -15 parts, 8-12 parts of glass fiber, 2-8 parts of glass beads, 1-10 parts of compatibilizer, 0.1-0.5 parts of antioxidant, 0.1-1 part of ultraviolet absorber, 0.1-0.5 part of antimicrobial agent , and 1-2 parts of anti-glass fiber leakage agent.

Embodiment 2

[0016] Embodiment 2, the present invention provides a special material for plastic glass reinforced plastic septic tanks, including the following raw materials in parts by weight: 40 parts of high-density polyethylene, 10 parts of acrylonitrile-butadiene-styrene, 5 parts of polyoxymethylene, glass fiber 8 parts, 2 parts of glass beads, 1 part of compatibilizer, 0.1 part of antioxidant, 0.1 part of ultraviolet absorber, 0.1 part of antimicrobial agent, and 1 part of anti-glass fiber leakage agent.

Embodiment 3

[0017] Embodiment three, the present invention provides a special material for plastic glass reinforced plastic septic tanks, including the following raw materials in parts by weight: 60 parts of high-density polyethylene, 20 parts of acrylonitrile-butadiene-styrene, 15 parts of polyoxymethylene, glass fiber 12 parts, 8 parts of glass beads, 10 parts of compatibilizer, 0.5 part of antioxidant, 1 part of ultraviolet absorber, 0.5 part of antimicrobial agent, and 2 parts of anti-glass fiber leakage agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com