Ocean engineering concrete corrosion-resistant coating and preparation method thereof

A corrosion-resistant coating and marine engineering technology, applied in the direction of coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of reducing the durability of concrete structures, cracking and cracking of concrete, and achieve extended service life and self-healing properties Effects of blocking, excellent adhesion and corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

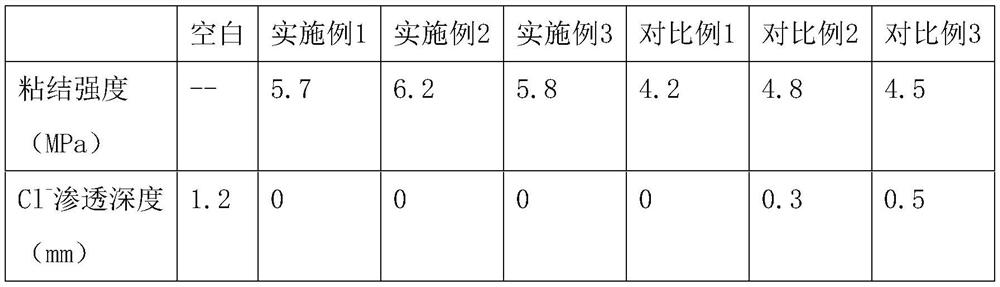

Embodiment 1

[0037] A marine engineering concrete corrosion-resistant coating, the corrosion-resistant coating is sprayed or brushed on the concrete surface after the A component and the B component are uniformly mixed,

[0038] Among them, component A includes by weight: 80 parts of water-based non-ionic epoxy resin, 5 parts of C10 alkyl glycidyl ether, 1 part of tridecafluorooctylpropyl cage silsesquioxane, and 2 parts of zinc powder , 1 part of magnesium aluminum hydrotalcite powder, 0.1 part of dispersant polyoxyethylene isodecyl ether, 0.1 part of silicone defoamer;

[0039] Among them, component B includes by weight: 50 parts of modified aromatic amine curing agent, 5 parts of C10 alkyl glycidyl ether, 5 parts of self-repairing microcapsules, 1 part of leveling agent silicone polyether copolymer, 1 part of oxidant 4-tert-butylcatechol, 0.1 part of adhesion promoter BYK-4511, 1 part of UV absorber 2-hydroxy-4-methoxybenzophenone.

[0040]The self-healing microcapsules are prepared by...

Embodiment 2

[0042] A marine engineering concrete corrosion-resistant coating, the corrosion-resistant coating is sprayed or brushed on the concrete surface after the A component and the B component are uniformly mixed,

[0043] Among them, component A includes by weight: 90 parts of water-based non-ionic epoxy resin, 8 parts of C11 alkyl glycidyl ether, 3 parts of dodecafluoroheptylpropyl cage silsesquioxane, and 2.5 parts of zinc powder , 1.5 parts of magnesium aluminum hydrotalcite powder, 0.3 parts of dispersant polyoxyethylene styryl phenyl ether, 0.3 parts of silicone defoamer;

[0044] Among them, component B includes by weight: 60 parts of modified aromatic amine curing agent, 8 parts of C11 alkyl glycidyl ether, 7 parts of self-repairing microcapsules, 1.5 parts of leveling agent silicone polyether copolymer, anti- Oxidant 2,2-methylene-bis(4-methyl-6-tert-butylphenol) 5 parts, adhesion promoter AP-507 0.7 parts, thickener carboxymethyl cellulose 2 parts.

[0045] The self-healin...

Embodiment 3

[0048] A marine engineering concrete corrosion-resistant coating, the corrosion-resistant coating is sprayed or brushed on the concrete surface after the A component and the B component are uniformly mixed,

[0049] Among them, component A includes by weight: 100 parts of water-based non-ionic epoxy resin, 10 parts of C12 alkyl glycidyl ether, 5 parts of dodecafluoroheptylpropyl cage silsesquioxane, and 3 parts of magnesium powder , 2 parts of magnesium aluminum hydrotalcite powder, 0.5 part of dispersant polyoxyethylene styryl phenyl ether, 0.5 part of silicone defoamer;

[0050] Among them, component B includes by weight: 50 parts of modified aromatic amine curing agent, 10 parts of C12 alkyl glycidyl ether, 10 parts of self-repairing microcapsules, 3 parts of leveling agent silicone polyether copolymer, anti- 5 parts of oxidizing agent 2,6-di-tert-butyl-p-cresol, 0.5 parts of adhesion promoter AP-507, and 3 parts of ultraviolet absorber 2-hydroxy-4-methoxybenzophenone.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com