Antiseptic and hydrophilic coating

A coating and hydrophilic technology, applied in the field of coatings and chemistry, to achieve the effect of simple operation process, low cost and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

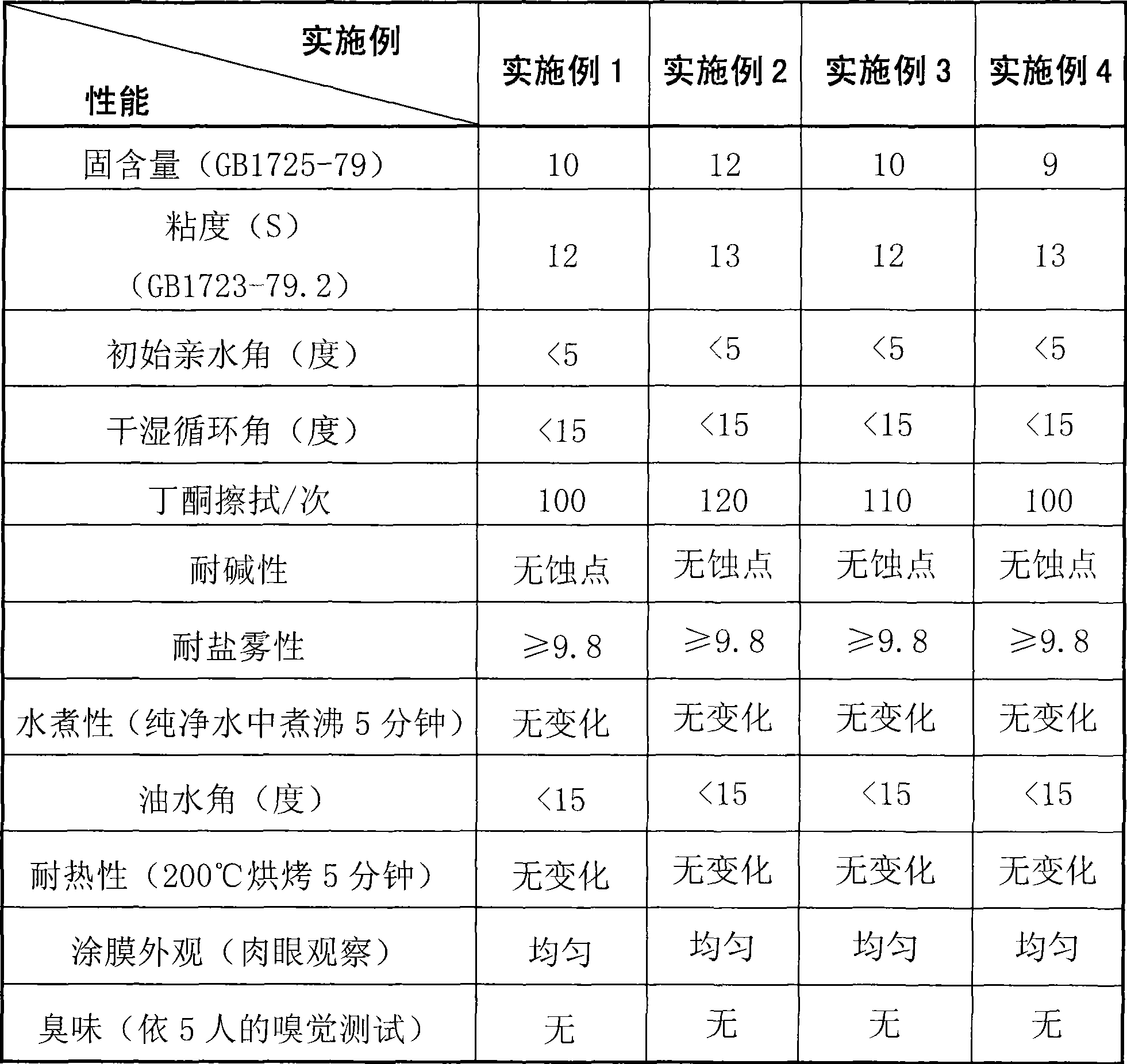

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments, but it is not meant to limit the protection scope of the present invention.

[0030] (1) Preparation of primer A

[0031] Weigh various raw materials according to the formula ratio, weigh appropriate amount of modified epoxy resin, modified acrylic resin, amino resin, ethylene glycol butyl ether, put them into the reaction kettle, start the stirrer, mix evenly, and add PH regulator Adjust the pH value of the system to 7-8, add metered distilled water to keep the solid content of the system at 25%, and prepare component A.

[0032] (2) Preparation of surface coating B

[0033] Weigh various raw materials according to the formula ratio, weigh an appropriate amount of functional monomers, methacrylic acid, and hydroxy acrylate, put them into the reaction kettle, start the stirrer, mix well, and then slowly add an appropriate amount of initiator and an appropriate amount of The composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com