Preparation method of special coke for ceramic fiber vertical melting furnace, special coke for ceramic fiber vertical melting furnace and application thereof

A ceramic fiber and vertical technology, which is applied in the field of special coke for ceramic fiber vertical melting furnaces. Simplicity, increased productivity, and reduced coal blending costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] According to a preferred embodiment of the present invention, the preparation method of the special coke for the ceramic fiber vertical melting furnace includes: mixing the blended coal and the binder and then performing dry distillation; the dry distillation process includes: first heating up to the Require dry distillation temperature, then carry out constant temperature dry distillation; The weight ratio of described mixed coal and binder is 100:2-12;

[0044] The blended coal includes coking coal, fat coal, 1 / 3 coking coal and lean coal; based on the total amount of the blended coal, the coking coal content is 40-85% by weight, and the fat coal content is 10-15% by weight %, the 1 / 3 coking coal content is 0-30% by weight, and the lean coal content is 5-15% by weight;

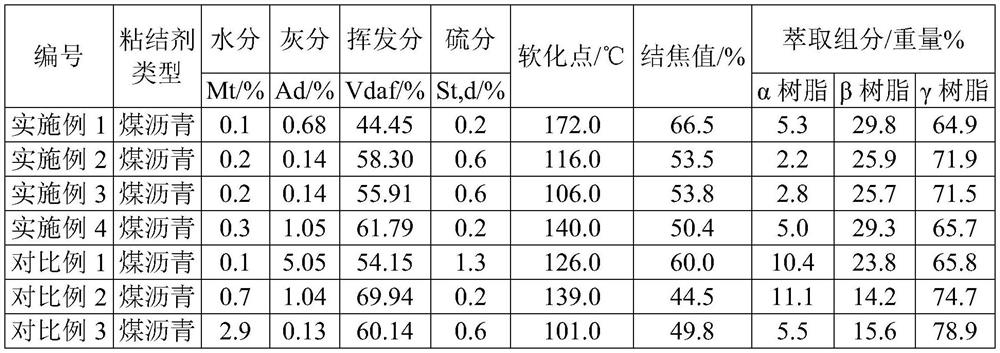

[0045] Wherein, the binder satisfies: the content of β resin is 25-30% by weight, the content of γ resin is 64-75% by weight, and the content of α resin is 0-6% by weight; the binder has the following...

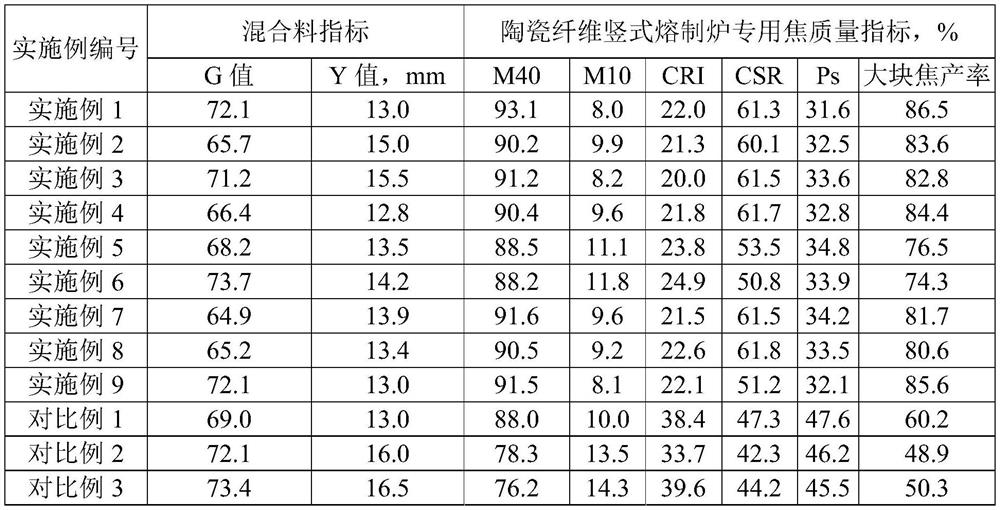

Embodiment 1

[0062] After mixing the blended coal and binder, carry out dry distillation to obtain special coke for ceramic fiber vertical melting furnace; the dry distillation process is as follows: firstly, heat up from room temperature at 1°C / min to 1050°C (i.e. dry distillation temperature), and then carry out constant temperature Dry distillation 170h. The weight ratio of the blended coal to the binder is 100:4.9. The indicators of the mixed material of the blended coal and binder are shown in Table 2.

[0063] Among them, the composition of blended coal is: 45.5% by weight of Xinjing (i.e. coking coal), 36.5% by weight of Xinyuan (i.e. 1 / 3 coking coal), 12% by weight of Xinsheng 2# (i.e. fat coal), 6% by weight of New promotion 9+10# (that is, lean coal). The blended coal has a particle size distribution: based on the total amount of blended coal, the part with a particle size of ≤0.5mm accounts for 8% by weight, the part with a particle size of 0.5-1mm accounts for 57% by weight, ...

Embodiment 2-4

[0068] According to the method of Example 1, the difference is that the binders are different, specifically the binders shown in Table 1 are used. The test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com