Electrolysis equipment for ammonium persulfate production

A technology of electrolysis equipment and ammonium persulfate, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of reducing the scope of application of the device, reducing the efficiency of electrolysis, and poor stability of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

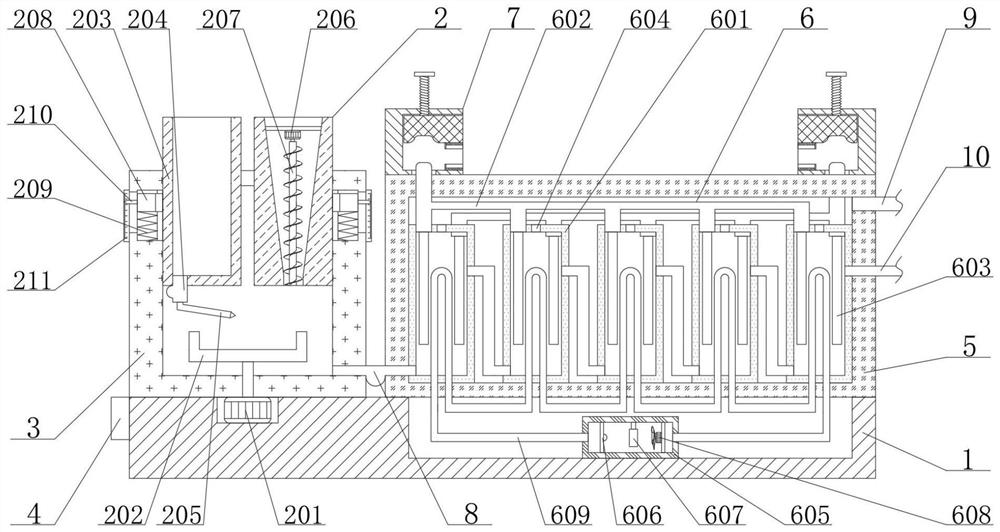

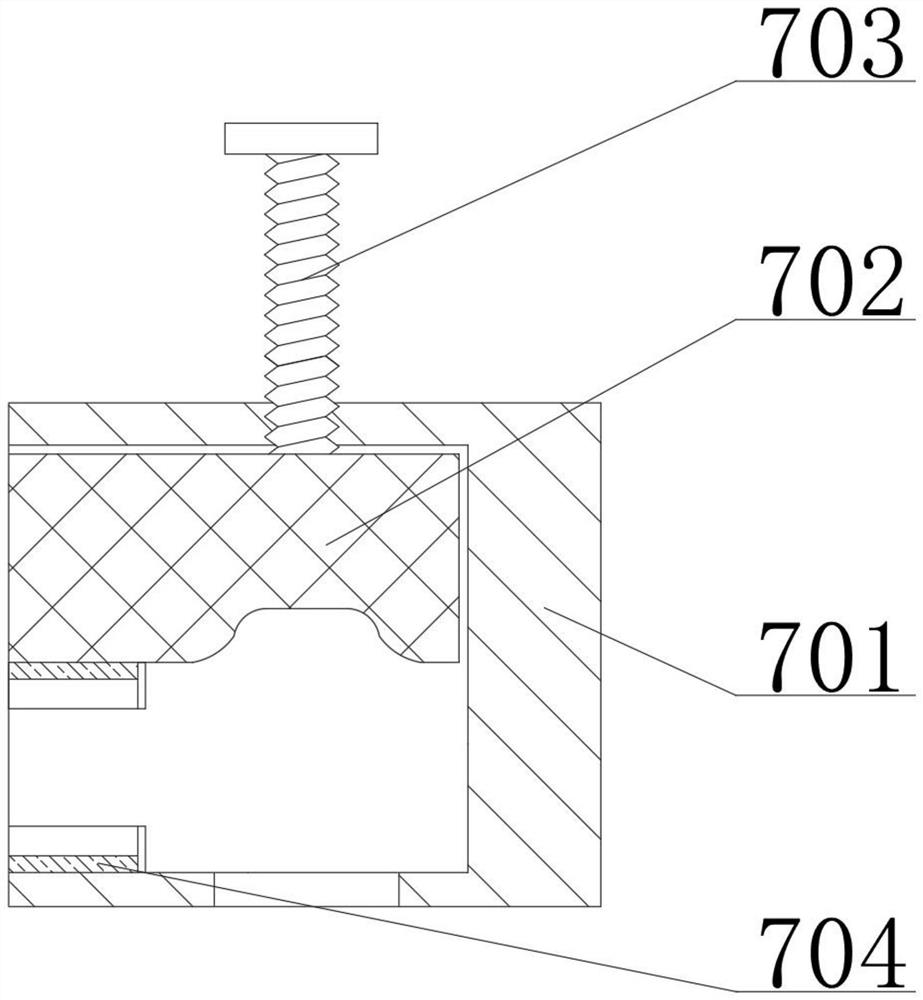

[0025] see figure 1 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0026]An electrolysis device for the production of ammonium persulfate, comprising a fixed seat 1, a proportioning device 2, an electrolysis device 6 and a wiring device 7, the left side of the top of the fixed seat 1 is fixedly connected with a fixed box 3, and the inner side of the fixed box 3 is provided with a proportioning device 2. The proportioning device 2 includes a first motor 201, and the center position of the bottom end of the fixed box 3 is fixedly connected with the first motor 201, and the main shaft of the first motor 201 runs through the fixed box 3, and the main shaft of the first motor 201 rotates with the fixed box 3 connection, the end of the main shaft of the first motor 201 is fixedly connected with the stirring rod 202, the inner top of the fixed box 3 is slidably connected with the placement box 203, and the bottom end of the placement...

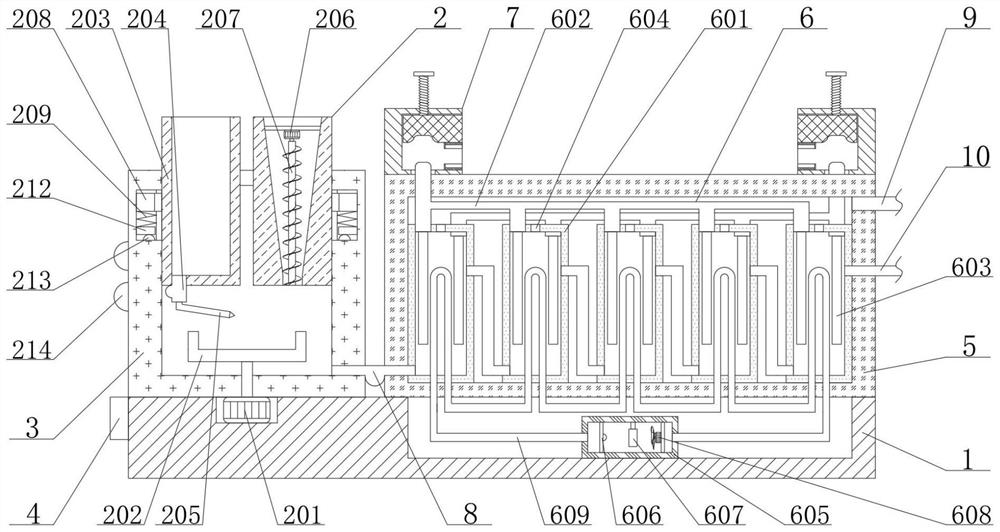

Embodiment 2

[0029] In embodiment 2, the same part as embodiment 1 will not be repeated, and the difference is: please refer to figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution: the proportioning device 2 includes a first motor 201, and the center position of the bottom end of the fixed box 3 is fixedly connected with the first motor 201, and the main shaft of the first motor 201 runs through the fixed box 3, and the first motor 201 The main shaft of the first motor 201 is rotatably connected with the fixed box 3, the end of the main shaft of the first motor 201 is fixedly connected with the stirring rod 202, the inner top of the fixed box 3 is slidably connected with the storage box 203, and the bottom of the storage box 203 on the left is connected with the second water pump 204 , the bottom end of the second water pump 204 is connected with the nozzle 205, and the inclination angle of the nozzle 205 is 30°, the inside of the storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com