Multilayer composite structure three-dimensional fabric and preparation method thereof

A technology of three-dimensional fabrics and combined structures, which is applied in the direction of fabrics, textiles, layered products, etc., and can solve the problems of poor connection performance between layers, long production cycle, and high preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

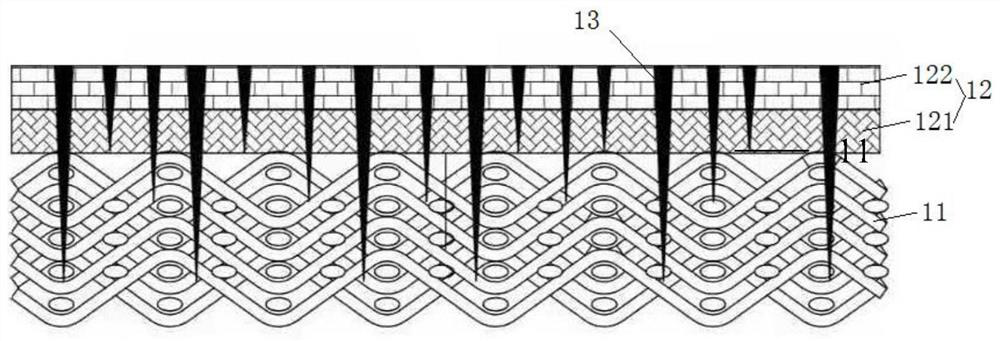

[0029] refer to figure 1 and figure 2 , the present embodiment provides a double-layer plate-shaped composite structure three-dimensional fabric comprising one structural unit, the three-dimensional fabric is a quartz fiber composite fabric, and its shape and size are 150*150*(15+20) mm. The structural unit is composed of a 2.5D structural layer 11 and a needle-punched structural layer; the 2.5D structural layer 11 is the bottom layer of the fabric, its thickness is 15 mm, and its bulk density is 0.9 g / cm 3 The needle-punched structure layer includes some needle-punched units 12 made up of five pieces of satin weave cloth 122 of one layer of quartz fiber and one layer of quartz fiber mesh tire 121, the thickness of the needle-punched structure layer is 20mm, and the bulk density is 0.4g / cm 3 .

[0030] The preparation method of the double-layer combined structure three-dimensional fabric of implementing 1 is:

[0031] (1) Preparation of 2.5D structure layer 11:

[0032] I...

Embodiment 2

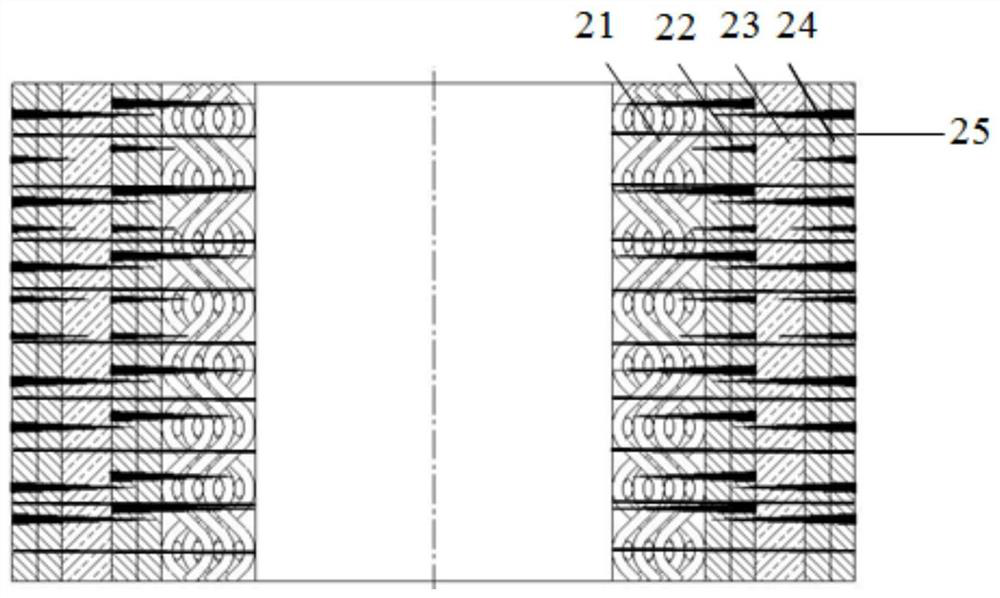

[0039] refer to figure 2 , the present embodiment provides a three-dimensional fabric with a cylindrical composite structure consisting of two structural units inside and outside. The three-dimensional fabric is a carbon fiber composite fabric, and the entire fabric is implanted with T700 12K carbon fibers in the Z direction. The shape and size of the fabric are Ф150*( 10+15+5+15)*150mm. The inner structural unit is composed of a 2.5D structural layer 21 and a first needle-punched structural layer 22. The 2.5D structural layer 21 is the inner fabric layer with a thickness of 10 mm and a bulk density of 0.8 g / cm 3 ; The first needle-punched structure layer 22 includes several layers with a layer density of 200g / m 2 Carbon fiber cloth and a layer density of 60g / m 2 An acupuncture unit composed of carbon fiber net tires, the thickness of the first acupuncture structure layer 15 is 15mm, and the bulk density is 0.5g / cm 3 The outer layer structure unit is made up of three-way o...

Embodiment 3

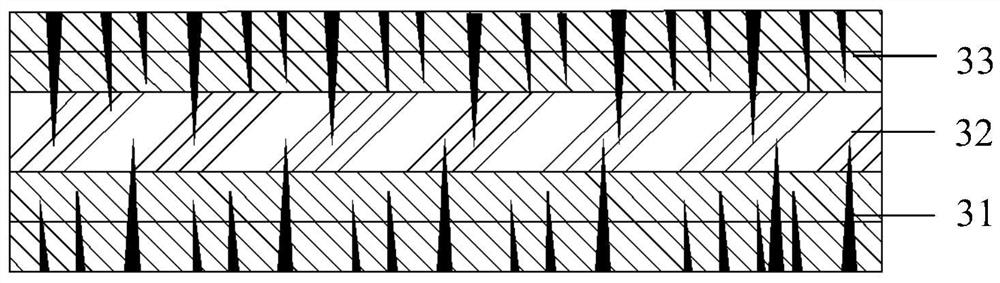

[0051] refer to image 3 , the present embodiment provides a double-layer plate-shaped combined structure three-dimensional fabric comprising a structural unit, the three-dimensional fabric is a combined fabric of mullite fiber and quartz fiber, and its shape and size are 150*150*(20+15+20) mm. The structural unit is composed of a finely punctured structure layer 32, a first needled structure layer 31 and a second needled structure layer 33; the first needled structure layer 31 is the bottom layer of the fabric, its thickness is 20 mm, and its bulk density is 0.7 g / cm 3 ; The finely punctured structure layer 32 is the middle layer of the fabric, the raw material is mullite fiber cloth, the Z direction is quartz fiber, and the surface density of the fiber cloth is 300g / m 2 , with a thickness of 15mm and a bulk density of 0.9g / cm 3 ; The second acupuncture structure layer 33 is the surface layer of the fabric, its thickness is 20mm, and the bulk density is 0.7g / cm 3 ; The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com