Tunnel hard rock micro-damage cutting device, system and method

A cutting device and cutting system technology, applied in tunnels, mining devices, earth-moving drilling, etc., can solve the problems of dust pollution, affecting the safety of construction workers, affecting construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

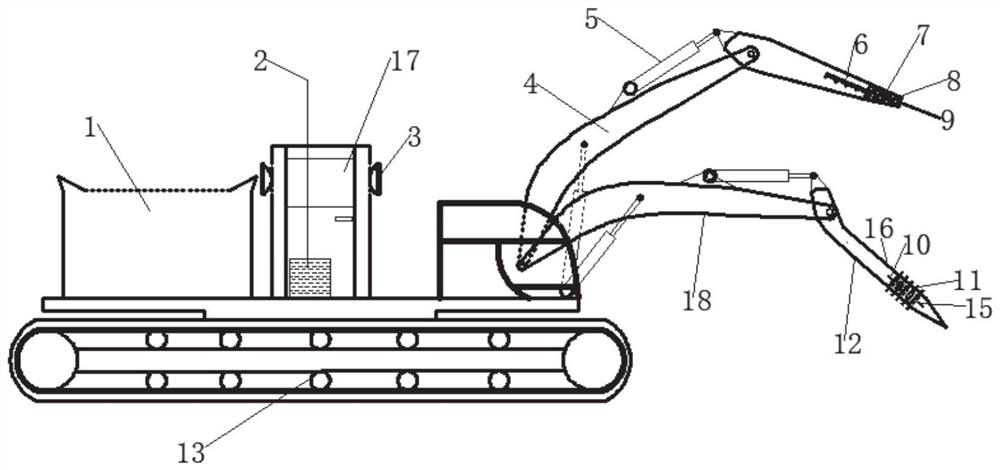

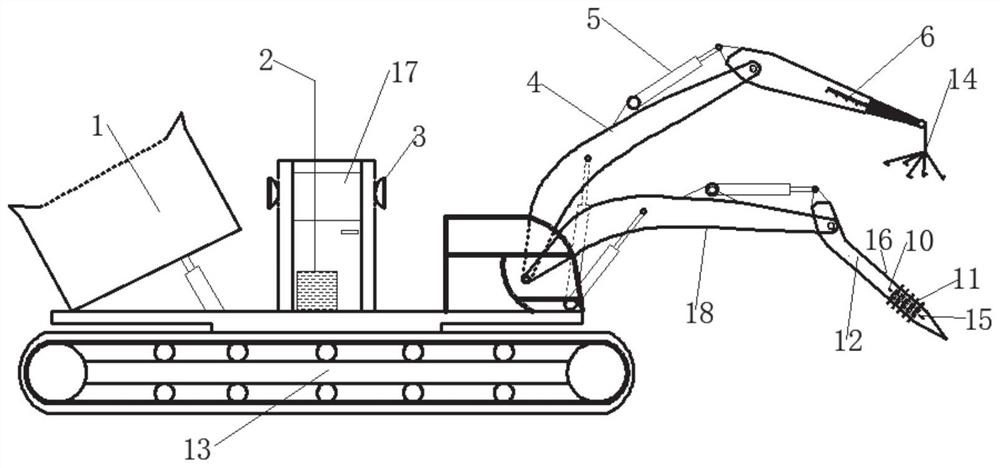

[0037] In a typical implementation of the present invention, this embodiment discloses a tunnel hard rock micro-damage cutting device 12, which includes a columnar body and multiple reciprocating mechanisms, and the multiple reciprocating mechanisms are connected to the side of the columnar body. Each reciprocating mechanism can reciprocate along the radial direction of the columnar body. During this process, the reciprocating mechanism can protrude beyond the side of the columnar body when it moves outward. When the columnar body moves, the outer surface of the reciprocating mechanism The end just can touch the hard rock around, thereby completes cutting action; The front end of columnar main body is spike-like, so that enter drilling hole; The front end of cylindrical main body is also equipped with image sensor 15.

[0038] In this embodiment, the reciprocating mechanism uses a hydraulic cylinder 11, and the hydraulic cylinder 11 is also connected to other components in the ...

Embodiment 2

[0043]In a typical implementation of the present invention, this embodiment discloses a tunnel hard rock micro-damage cutting system, including a car body 13, a hard rock drilling construction unit, a hard rock cutting construction unit, a self-unloading tipping bucket 1, and a visual operation The terminal, wherein, the hard rock drilling construction unit, the hard rock cutting construction unit, the dump bucket 1 and the visual operation terminal are all installed on the vehicle body 13 .

[0044] The hard rock drilling construction unit in this embodiment uses the tunnel hard rock micro-damage cutting device 12 in Embodiment 1. Other mechanisms capable of expanding the borehole can also be used, and details will not be repeated here.

[0045] Further, the hard rock drilling construction unit includes a first power arm 4 and a drilling device 7, the first power arm 4 is installed on a crawler trolley, and the front end of the first power arm 4 is detachably connected to the...

Embodiment 3

[0063] In a typical implementation of the present invention, this embodiment discloses a method for micro-damage cutting of hard rock in tunnels. Using the system in Embodiment 2, the four columns of hydraulic cylinders 11 are respectively named as the first hydraulic cylinder 11, The second hydraulic cylinder 11, the third hydraulic cylinder 11 and the fourth hydraulic cylinder 11, wherein the first hydraulic cylinder 11 and the third hydraulic cylinder 11 are vertically arranged, and the second hydraulic cylinder 11 and the fourth hydraulic cylinder 11 are horizontally arranged, so the first hydraulic cylinder 11 and the third hydraulic cylinder 11 are arranged horizontally. One hydraulic cylinder 11 and the third hydraulic cylinder 11 can be called longitudinal hydraulic cylinder 11, and the second hydraulic cylinder 11 and the fourth hydraulic cylinder 11 can be called horizontal hydraulic cylinder 11, including the following steps:

[0064] Step 1: Preliminary preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com