Damage monitoring method and system for fan blade protective paint based on audio signals

An audio signal and damage monitoring technology, applied in the direction of wind turbines, wind turbine monitoring, engines, etc., can solve the problem of not monitoring the damage of the protective paint on the leading edge of the blade, so as to save data processing procedures, improve data processing efficiency, and ensure high efficiency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] In this embodiment, an audio signal collected in real time by a certain wind field is used as a case for introduction.

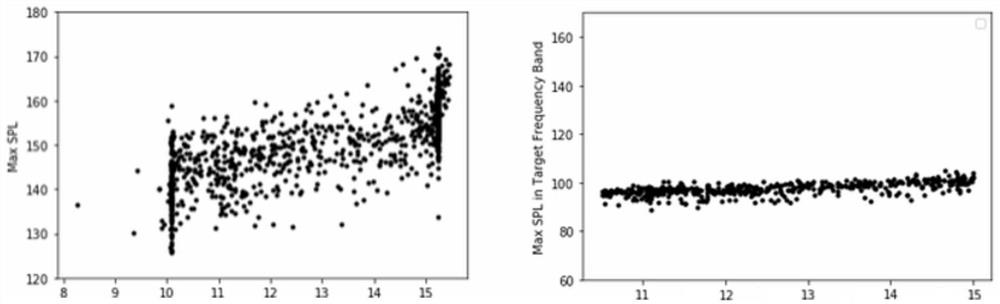

[0056] image 3 It is a comparison chart of the relationship between the original data and the rotational speed and the maximum sound pressure level after data filtering and frequency band selection. The left side is the original data, and the right side is the data after data filtering and target frequency band selection. The abscissa is the rotation speed, and the ordinate is Maximum sound pressure level (Max SPL). It can be seen that the energy level of the entire frequency band of the original data has a certain linear relationship, but the variance is large, and the difference between the rated speed and some specific speeds is significantly larger. After screening data such as speed and recalculating the energy level by selecting frequency bands with obvious sweeping sound characteristics, the linear relationship between the maximum sound press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com