Kitchen and incineration integrated cooperative treatment process

A co-processing and process technology, applied in incinerators, biomass post-processing, biomass pre-processing, etc., can solve the problem of increasing investment costs and operation and management costs, difficulty in controlling odor and surrounding environment, and inability to realize resource integration. Utilize and other issues to achieve the effect of reducing cost, optimizing building layout, and improving profitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

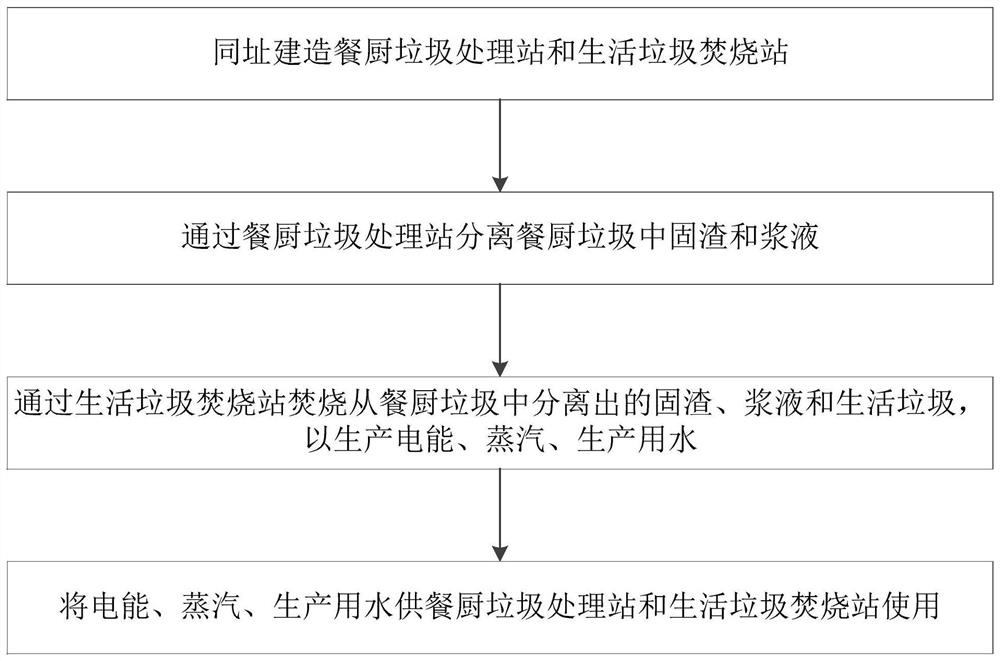

[0024] figure 1 It is a flow chart of the integrated collaborative treatment process of kitchen and incineration of the present invention.

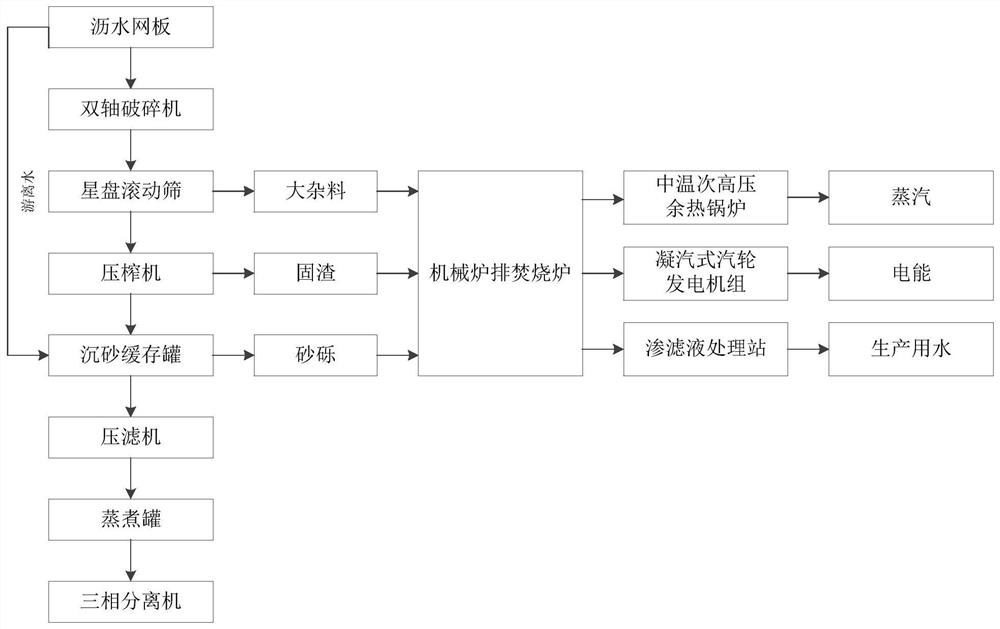

[0025] In this example, if figure 1 As shown, this embodiment provides an integrated collaborative treatment process for kitchen and incineration, which includes: constructing a kitchen waste treatment station and a domestic waste incineration station at the same site; and slurry; the solid slag, slurry and domestic waste separated from food waste are incinerated through the domestic waste incineration station to produce electricity, steam, and production water; the electricity, steam, and production water are supplied to the food waste treatment station and domestic waste Incineration station use.

[0026] In this embodiment, by building a food waste treatment station and a domestic waste incineration station on the same site, it is possible to realize simultaneous design, simultaneous construction, and simultaneous operation. By shari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com