Energy-saving high-efficiency drying tank

A high-efficiency, drying tank technology, used in drying solid materials, dry cargo handling, drying chambers/containers, etc., can solve the problems of low drying efficiency and low utilization rate of heat, and achieve improved utilization, improved uniformity and Efficiency, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

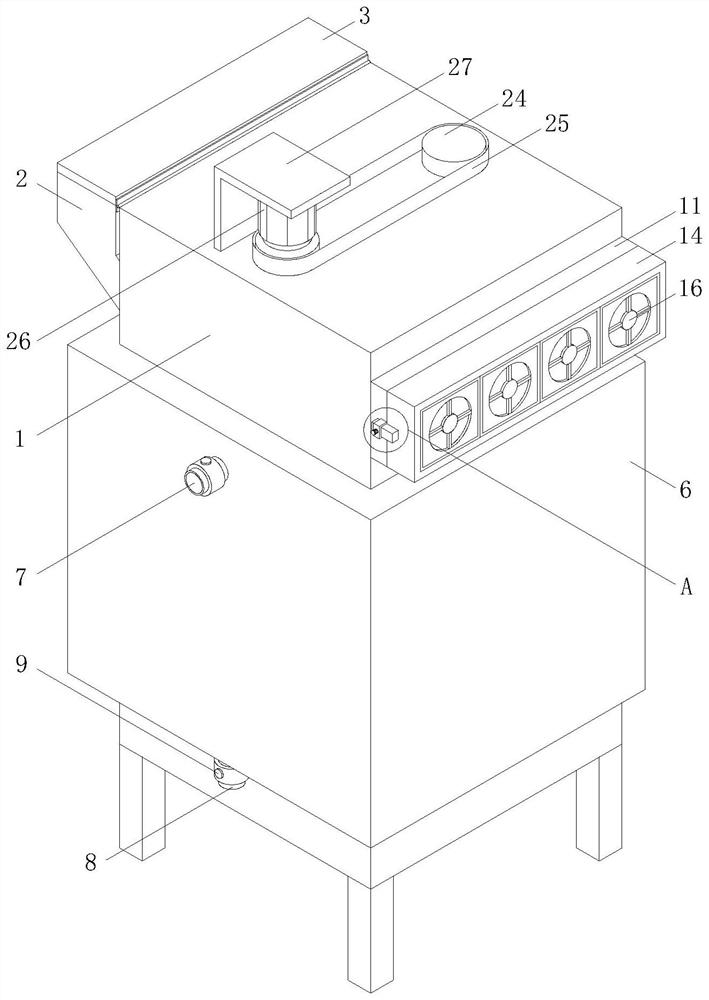

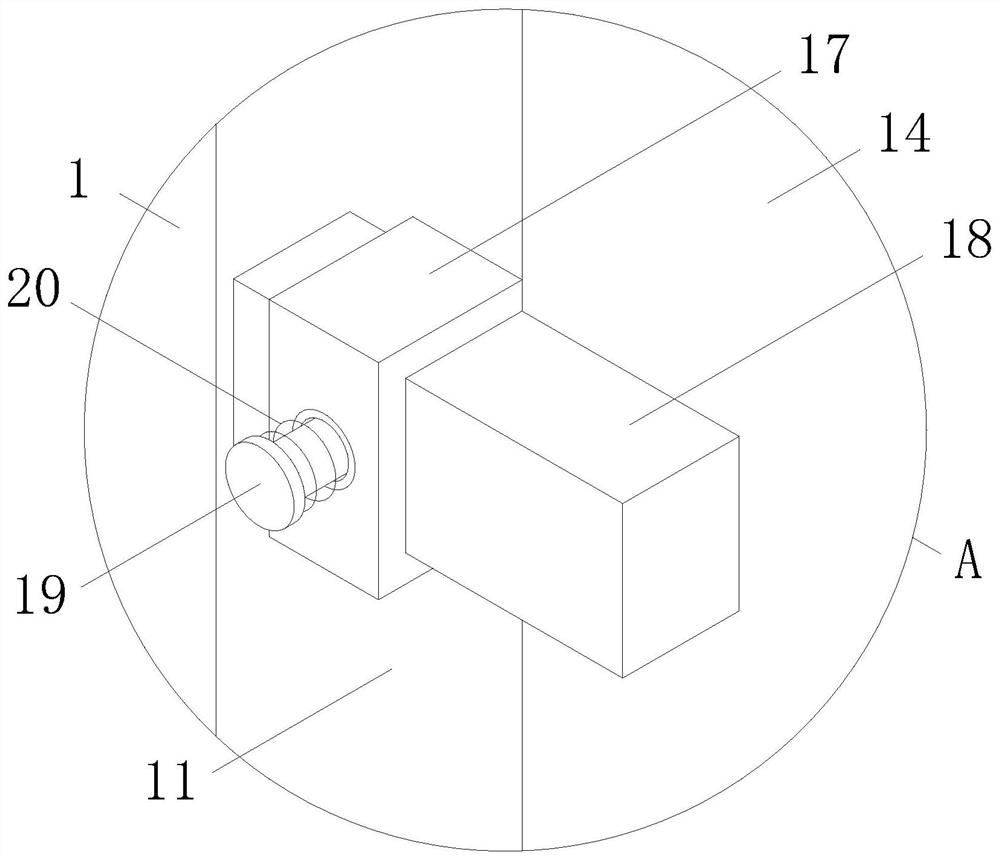

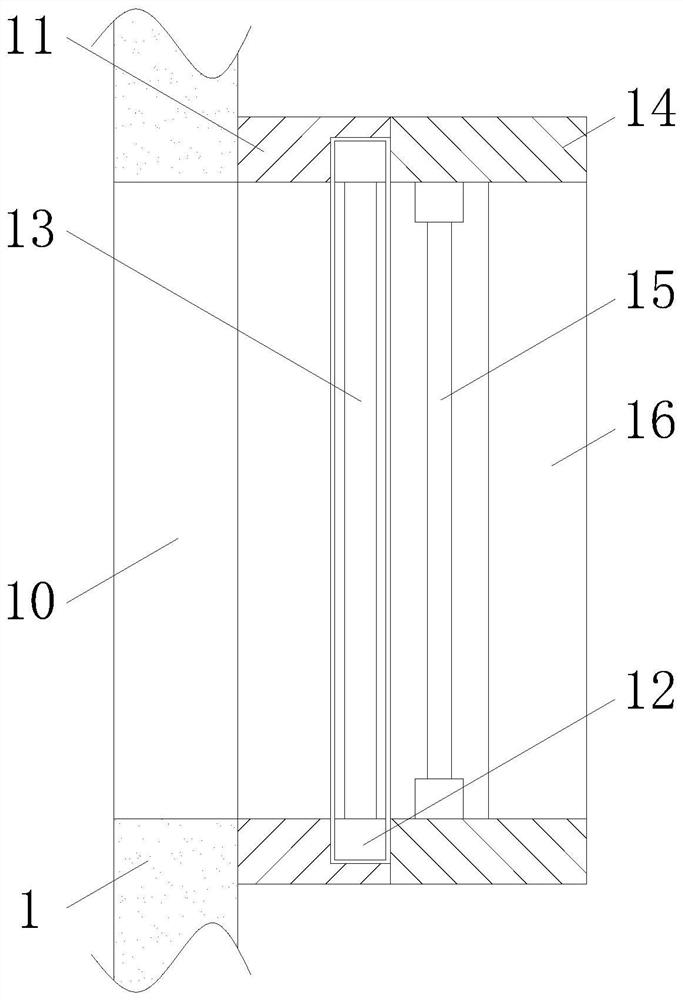

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, an energy-saving high-efficiency drying tank of the present invention includes a tank body 1, the top of the back of the tank body 1 is provided with a hopper 2 and a cover plate 3, and the middle part of the bottom end of the tank body 1 is fixedly connected with a discharge pipe 4. The middle part of the material pipe 4 is fixedly installed with a first valve 5, and the middle part of the tank body 1 is provided with a heat recovery mechanism. The heat recovery mechanism consists of a water tank 6, a water inlet pipe 7, a drain pipe 8 and two second valves 9. The top of the front of the tank body 1 is provided with a rectangular hole 10, and the top of the front of the tank body 1 is provided with a dust-proof mechanism. The dust-proof mechanism is composed of a connecting frame 11, a frame 12 and a filter screen 13. Inside the connecting frame 11, the front of the connecting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com