Product reflective surface defect detection method and system

A defect detection and product technology, which is applied in the direction of optical defect/defect test, measuring device, material analysis through optical means, etc. It can solve the problems of unstable effect, curved reflection in the area to be tested, and high work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

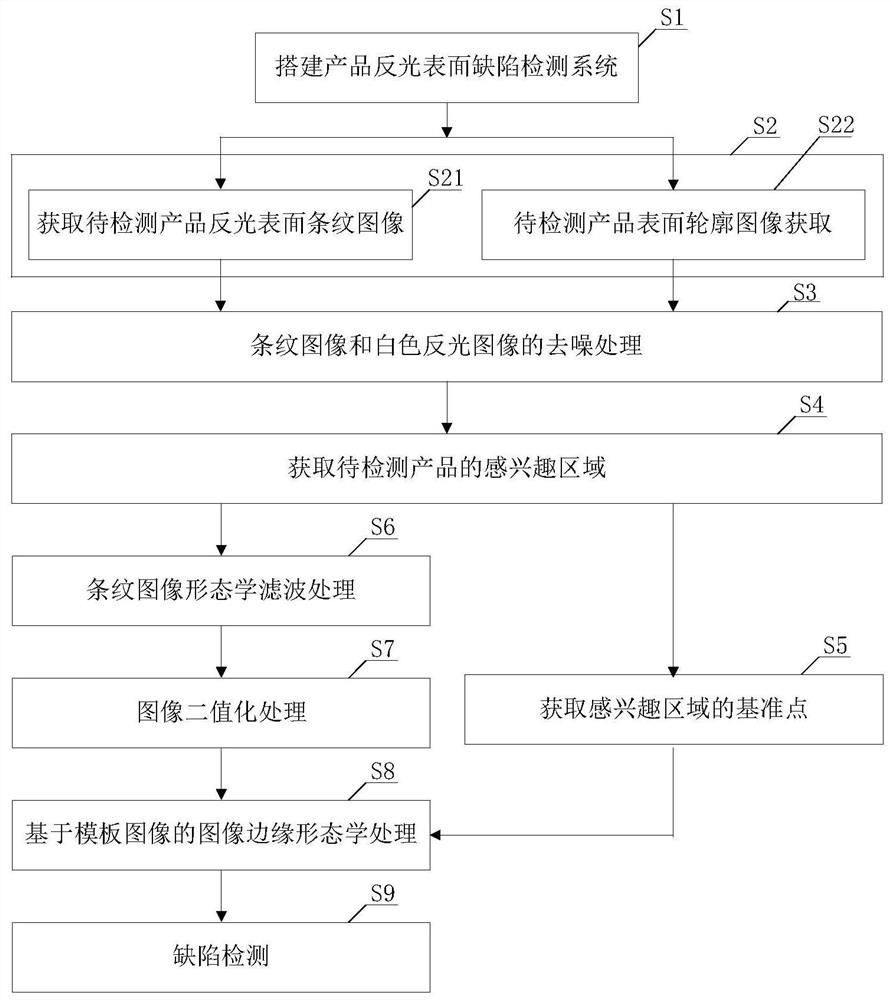

[0030] Such as figure 1 and 2 As shown, the present invention provides a method for detecting defects on the reflective surface of a product, comprising the following steps:

[0031] S1: Build a product reflective surface defect detection system. The present invention adopts the structure of oblique projection and forward shooting, that is, high-brightness liquid crystal display is used as the illumination source, and it is placed obliquely above the product to be detected, so that the angle between the screen of the display and the horizontal plane is 20°, and the displays respectively form different images and Projected onto the product to be inspected. The industrial camera is placed directly above the product to be inspected, and focuses on the surface of the product to be inspected for image acquisition. During the image acquisition process, the industrial camera, the product to be inspected, and the lighting source are all placed in a closed environment.

[0032] S2: ...

Embodiment 2

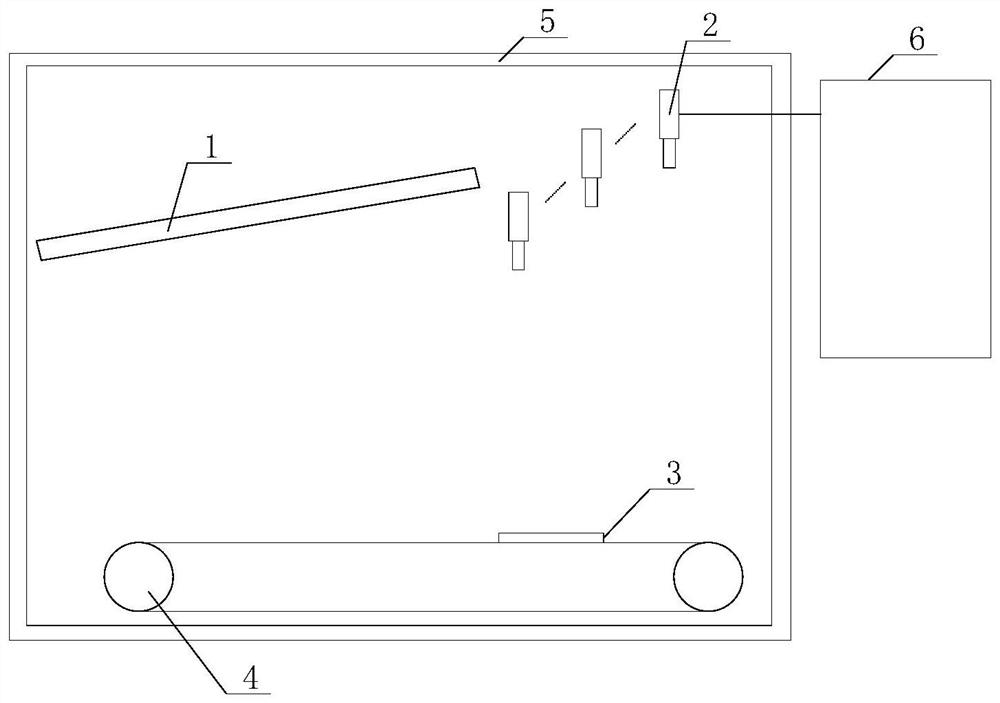

[0050] Such as figure 1 As shown, the present invention provides a product reflective surface defect detection system, including: a display 1, an industrial camera 2, an image processing device 6, a mechanical transmission device 4, and a product fixing fixture.

[0051] The display 1 is used as an illumination source to generate an image and project it onto the product 3 to be inspected. The display 1 is located obliquely above the product 3 to be inspected, and the angle between the screen of the display 1 and the horizontal plane is 20°.

[0052] The industrial camera 2 is located directly above the product 3 to be inspected, and is used to focus on the surface of the product 3 to be inspected for image collection, and upload the collected image data to the image processing device 6 . The number of industrial cameras 2 can be selected as multiple.

[0053] The image processing device 6 is used to obtain the image collected by the industrial camera 2, and perform image proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com