Hydrogen sulfide leakage monitoring and arresting test system and method

A test system and test method technology, applied in the direction of chemical instruments and methods, separation methods, general control systems, etc., can solve problems such as single function and difficulty in simulating different working conditions, and achieve improved safety, convenient operation, and accurate test results and full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

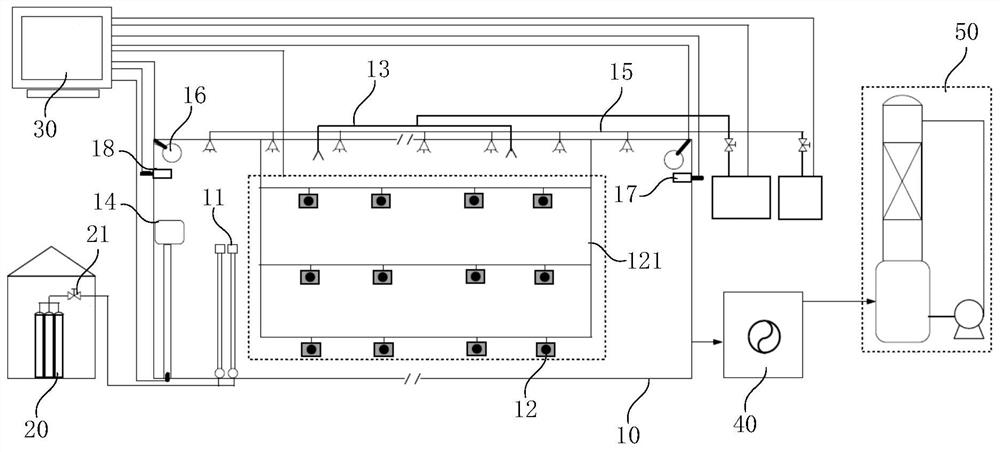

[0049] refer to figure 1 As shown, 36 hydrogen sulfide concentration detectors 12 are arranged in the confined space of the test cabin 10 of the hydrogen sulfide leakage monitoring and capture and elimination test system of the present embodiment, which are divided into three layers of height distribution, and each layer of hydrogen sulfide concentration detectors 12 are distributed in a 4×3 matrix. In this embodiment, a hydrogen sulfide release device 11 , a fan device 14 and a water mist spray device 15 which can be moved and adjusted in height are installed in the test chamber 10 , which can simulate and monitor the leakage concentration of hydrogen sulfide gas.

[0050] In the present embodiment, the hydrogen sulfide gas of 1000ppm is evenly configured in the test cabin 10, after 500mL of pure water is sprayed by the scavenger injection device 13, and the reaction treatment is carried out for 10min, the two hydrogen sulfide concentrations in the middle of the middle altitu...

Embodiment 2

[0053] The hydrogen sulfide leakage monitoring and capture and elimination testing system of this embodiment is basically the same as that of Embodiment 1.

[0054] In this embodiment, the hydrogen sulfide gas of 1000ppm is evenly arranged in the test chamber 10, and the scavenger sprayed by the scavenger injection device 13 is an aqueous NaOH solution with a mass concentration of 1.0%, and the injection volume is 100mL, and the reaction treatment is 10min. The concentration of hydrogen sulfide gas detected by the two hydrogen sulfide concentration detectors 12 in the middle of the middle altitude layer in 10 is 55ppm.

[0055] In this embodiment, the pure water of the scavenger and scavenger in Example 1 is replaced with an aqueous solution of NaOH having a mass concentration of 1.0%, so that the performance of different scavenger and scavenger can be quantitatively evaluated.

Embodiment 3

[0057] The hydrogen sulfide leakage monitoring and capture and elimination testing system of this embodiment is basically the same as that of Embodiment 1.

[0058] In this embodiment, the hydrogen sulfide gas of 1000ppm is evenly arranged in the test chamber 10, and 0.5mol / L of FeCl is injected through the scavenger injection device 13. 3 Aqueous solution, injection volume is 100mL, reaction treatment is 10min, and the concentration of hydrogen sulfide gas detected by the two hydrogen sulfide concentration detectors 12 in the middle of the middle altitude layer in the test chamber 10 is 820ppm.

[0059] In this embodiment, the scavenger pure water of embodiment 1 is replaced with 0.5mol / L FeCl 3 Aqueous solution can quantitatively evaluate the performance of different scavenger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com