RGBW-based Micro-LED photoetching process

A photolithography process and photoresist technology, which is applied to the photolithography process of the pattern surface, micro-lithography exposure equipment, photo-plate process exposure device, etc., can solve the problem of different thicknesses of sealants and uneven brightness of sub-pixels, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

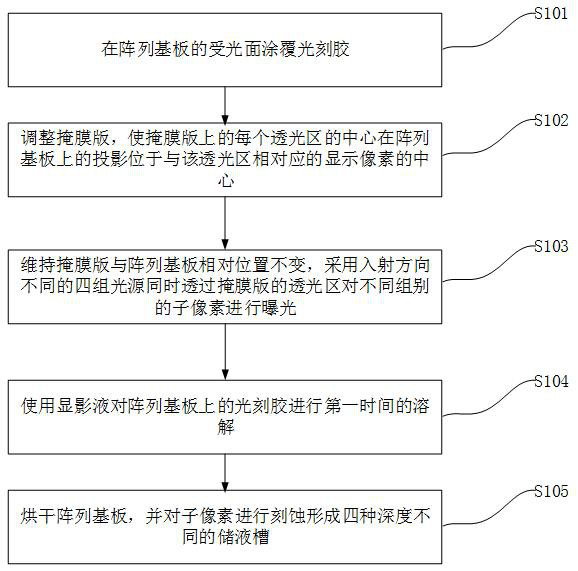

Method used

Image

Examples

Embodiment Construction

[0041]The present invention discloses RGBW-based micro-LED photolithography processes, and those skilled in the art can learn from the content, appropriate improvement of technical details. It is particularly important to note that all similar replacement and modifications will be apparent to those skilled in the art, which are considered to be included in the present invention. The method and application of the present invention have been described by a preferred embodiment, and the relevant personnel can be achieved without departing from the methods and applications described herein without departing from the spirit and apparatus of the present invention. Application techniques are applied.

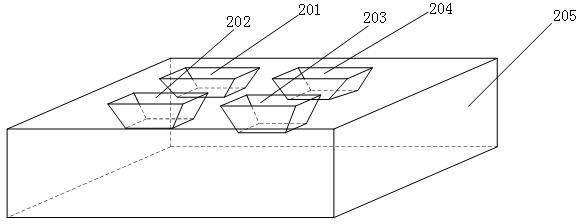

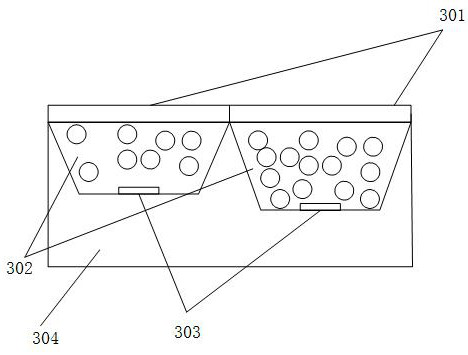

[0042]In a micro-LED display technology, the quantum points corresponding to different color sub-pixels produce the energy of light absorption of the same brightness, which results in a different body-type quantum dot colloid with different color sub-pixels.

[0043]However, in the conventional te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com