Preparation method of TiB2 enhanced high-entropy alloy powder for 3D printing

A high-entropy alloy, 3D printing technology, applied in metal processing equipment, additive processing, transportation and packaging, etc., to achieve the effect of unchanged elongation, improved comprehensive mechanical properties, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

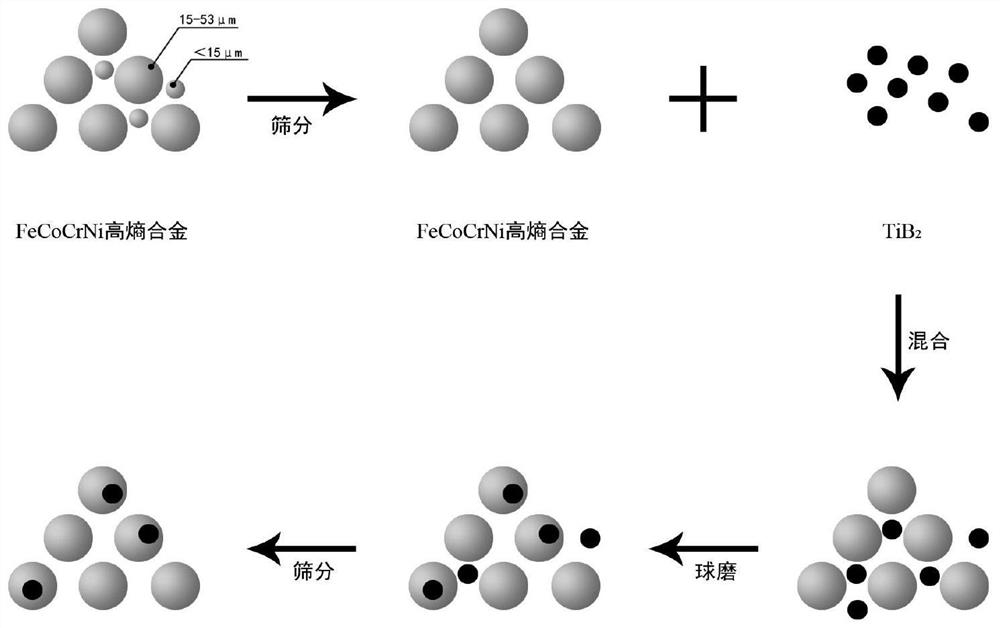

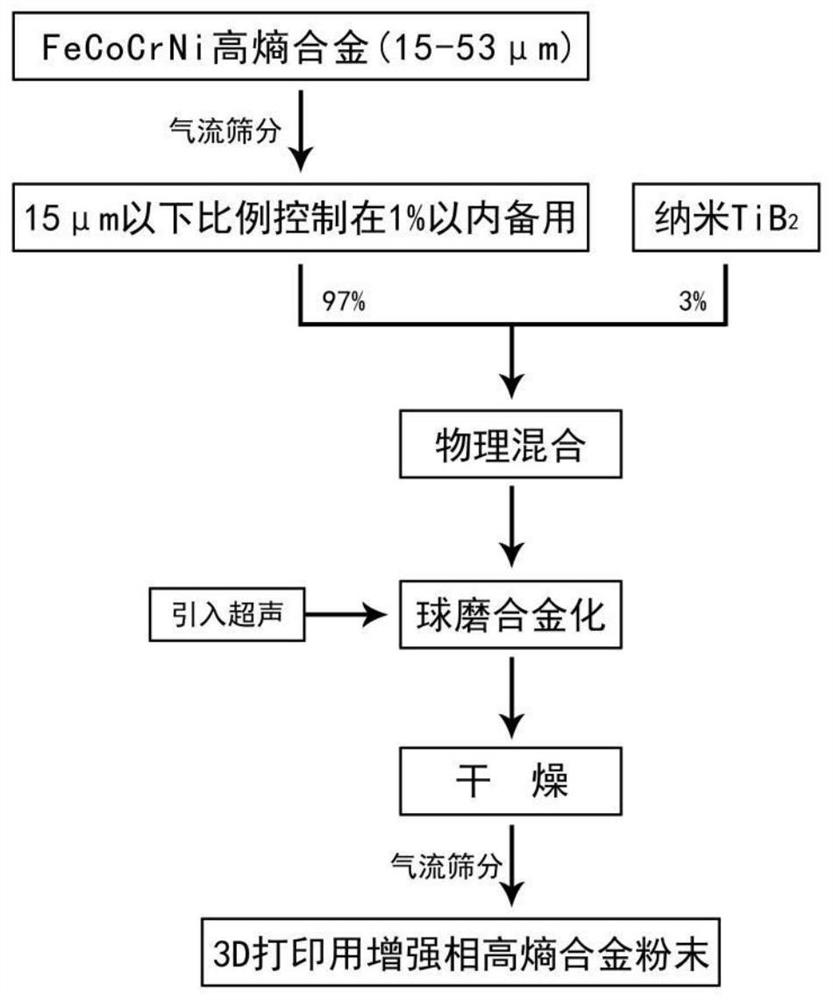

[0025] The invention discloses a TiB 2 The method for preparing high-entropy alloy powders for enhanced 3D printing, the innovations of which are as follows: figure 1 , 2 Shown: Include the following steps:

[0026] (1) Classify the FeCoNiCr high-entropy alloy with a size of 15-53 μm through air flow, and control the weight ratio of the powder below 15 μm within 1% for later use;

[0027] (2) Nano-TiB 2 The first part of the sieved high-entropy alloy powder is placed in a mixer in a mass fraction of 3:97 and fully mixed;

[0028] (3) Place the mixed metal powder on a ball mill for ball milling, and introduce ultrasonic waves around the ball mill, and mechanically alloy the nano-TiB 2 Embedded in high-entropy alloy powder;

[0029] (4) Put the ball-milled high-entropy alloy powder into a drying oven to dry;

[0030] (5) The dried ball-milled high-entropy alloy powder is classified by airflow to ensure that the weight ratio of the powder below 15 μm is controlled within 1%...

Embodiment 1

[0041] The preparation method and parameter settings of this embodiment are specifically:

[0042] (1) Classify the FeCoNiCr high-entropy alloy with a size of 15-53 μm through air flow, and control the weight ratio of the powder below 15 μm within 1% for later use;

[0043](2) Nano-TiB 2 The first part of the sieved high-entropy alloy powder is placed in a mixer in a mass fraction of 3:97 and fully mixed;

[0044] (3) Place the mixed metal powder on a ball mill for ball milling, and introduce ultrasonic waves around the ball mill, and mechanically alloy the nano-TiB 2 Embedded in high-entropy alloy powder;

[0045] (4) Put the ball-milled high-entropy alloy powder into a drying oven to dry;

[0046] (5) The dried ball-milled high-entropy alloy powder is classified by airflow to ensure that the weight ratio of the powder below 15 μm is controlled within 1%.

[0047] The weight fractions of the elements of the FeCoNiCr high-entropy alloy are Fe: 20%, Mn: 35%, Cr: 10%, Co: 3%...

Embodiment 2

[0053] The preparation method and parameter settings of this embodiment are specifically:

[0054] (1) Classify the FeCoNiCr high-entropy alloy with a size of 15-53 μm through air flow, and control the weight ratio of the powder below 15 μm within 1% for later use;

[0055] (2) Nano-TiB 2 The first part of the sieved high-entropy alloy powder is placed in a mixer in a mass fraction of 3:97 and fully mixed;

[0056] (3) Place the mixed metal powder on a ball mill for ball milling, and introduce ultrasonic waves around the ball mill, and mechanically alloy the nano-TiB 2 Embedded in high-entropy alloy powder;

[0057] (4) Put the ball-milled high-entropy alloy powder into a drying oven to dry;

[0058] (5) The dried ball-milled high-entropy alloy powder is classified by airflow to ensure that the weight ratio of the powder below 15 μm is controlled within 1%.

[0059] The weight fractions of the elements of the FeCoNiCr high-entropy alloy are Fe: 20%, Mn: 35%, Cr: 10%, Co: 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com