Automatic pipe clamp and gasket feeding equipment for planing cutter

A technology of gaskets and pipe clamps, applied in metal processing equipment, conveyor objects, metal processing, etc., can solve problems such as low production efficiency of planer teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

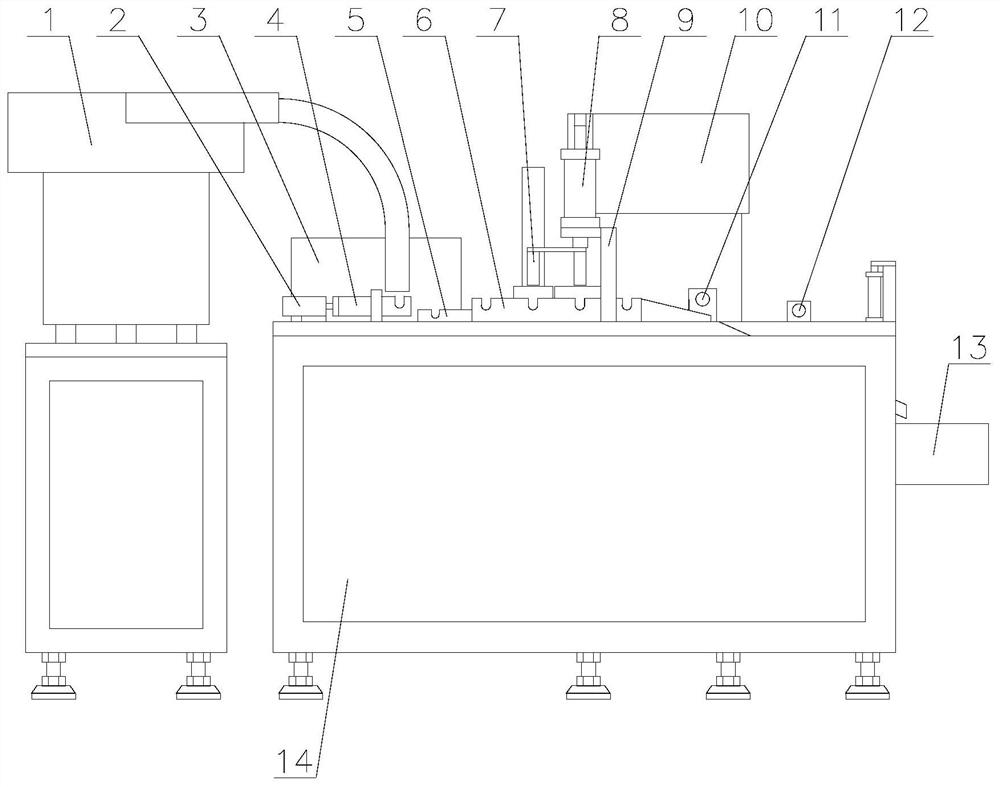

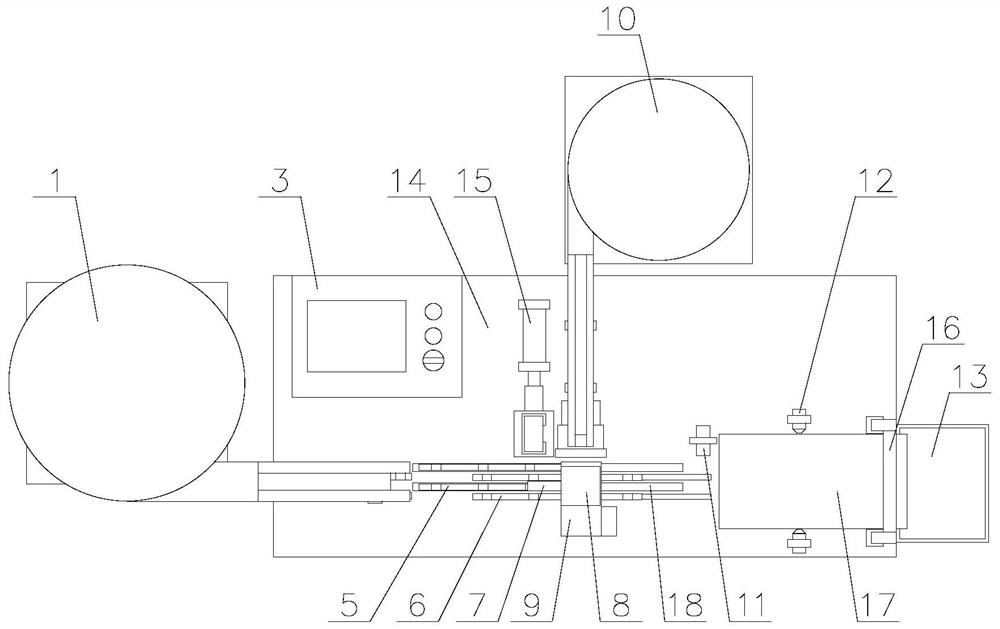

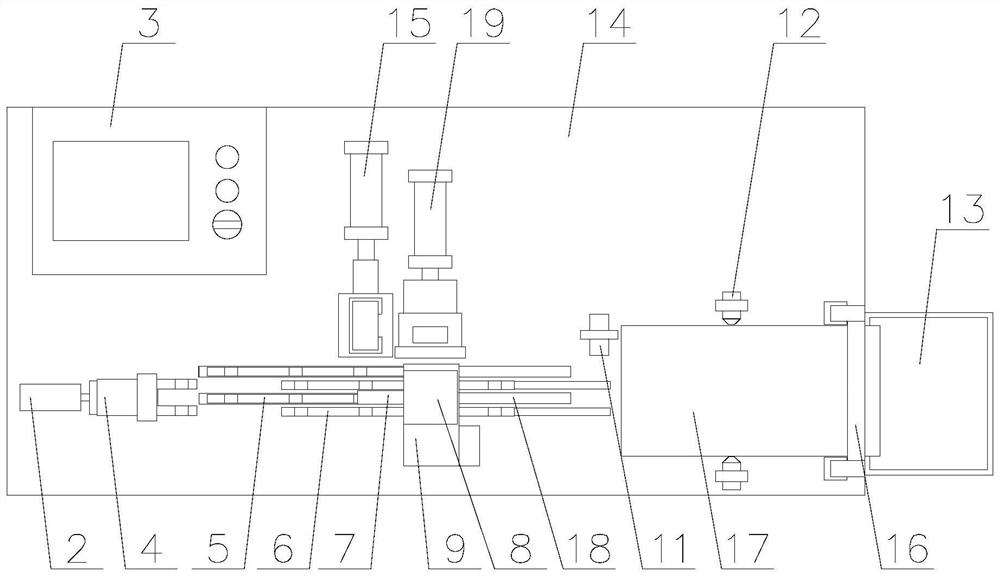

[0025] In order to better understand the purpose, structure and function of the present invention, the following is a further detailed description of the automatic pipe clip shim equipment for planing teeth according to the present invention in conjunction with the accompanying drawings.

[0026] Such as Figure 1-3 As shown in the figure, a pipe clamp gasket equipment for automatic loading of road teeth includes a worktable 14, a conveying mechanism and a center console 3 are installed on the top of the workbench 14, and a road tooth feeding device is installed at the starting end of the conveying mechanism. The planer tooth is sent to the conveying mechanism through the planer tooth feeding device. One side of the conveying mechanism is provided with a pipe clip installation device and a gasket installation device along the moving direction of the conveying mechanism. During the process of conveying the planer tooth by the conveying mechanism, The pipe clip installation devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com