Lotus sprout cutting equipment for food processing

A cutting equipment and food processing technology, applied in metal processing and other directions, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effects of improving work efficiency, facilitating subsequent collection, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

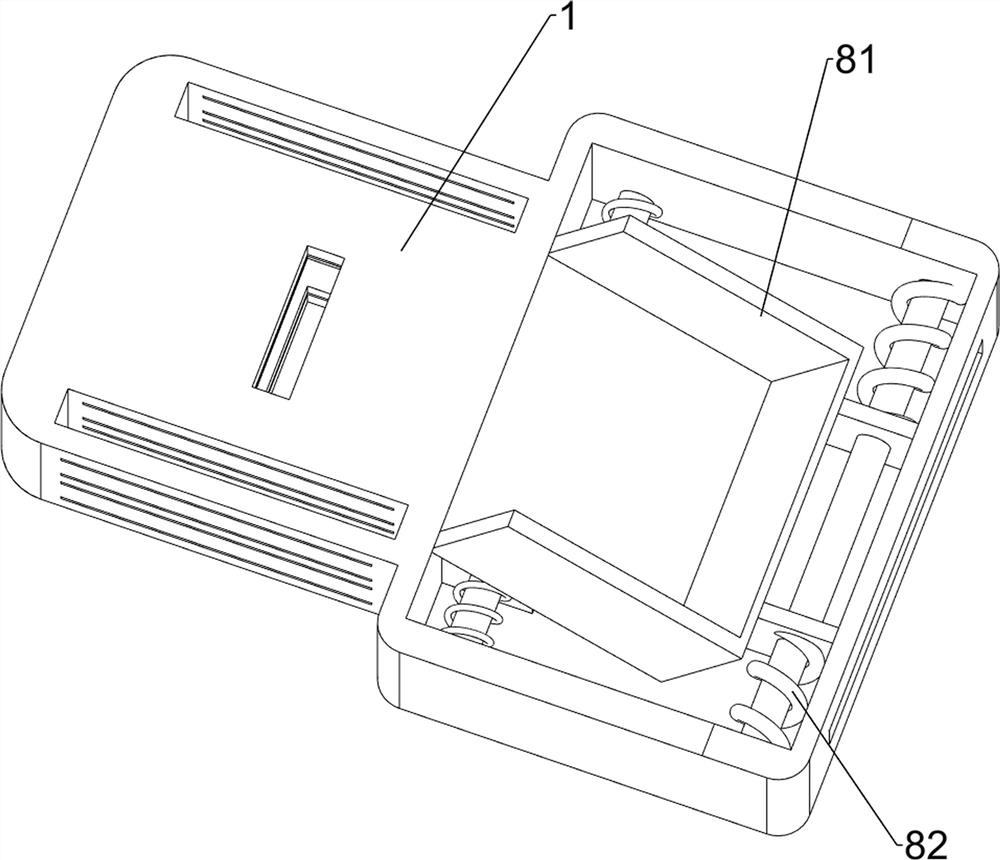

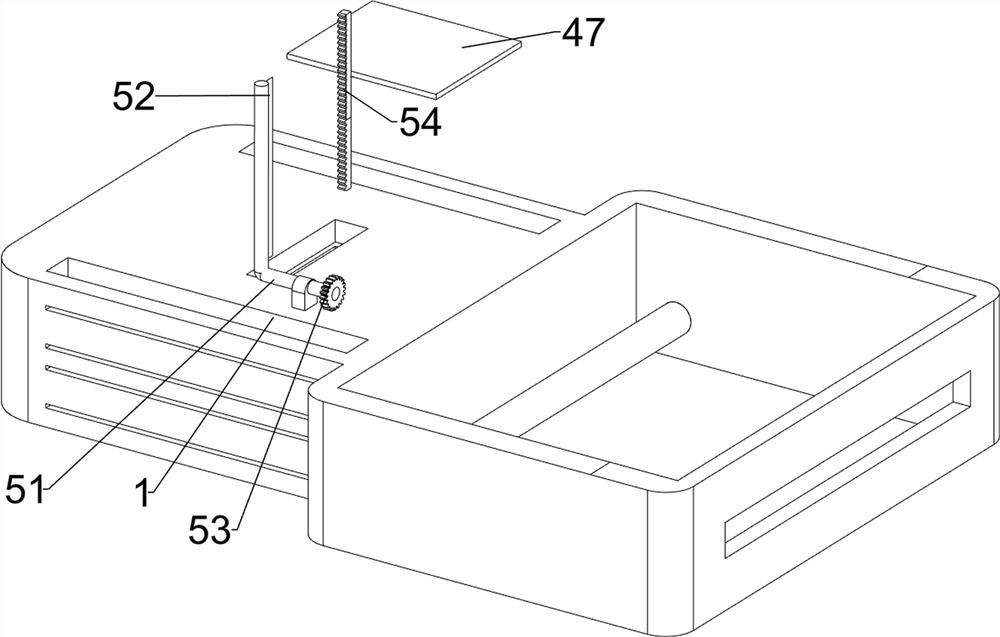

[0032] A kind of equipment for cutting lotus root strips for food processing, such as Figure 1-4 As shown, it includes a support 1, a support rod 2, a support rod 3, a clamping assembly 4 and a cutting assembly 5. The support rod 2 is connected to the front side of the top of the support 1, and the support rod 3 is connected to the front and rear sides of the left part of the support 1. A clamping assembly 4 is connected in the middle of the top of the support 1 , and a cutting assembly 5 is rotatably connected to the front side of the top of the support 1 .

[0033] The clamping assembly 4 includes a storage basket 41, a first rotating shaft 42, a side plate 43, a torsion spring 44, a top plate 45, a cylinder 46, a pressure plate 47, a slide plate 48 and a first spring 49, and a storage basket is connected in the middle of the top of the support 1 41, the rear side of the right part of the storage basket 41 is rotatably connected with a first rotating shaft 42, the front sid...

Embodiment 2

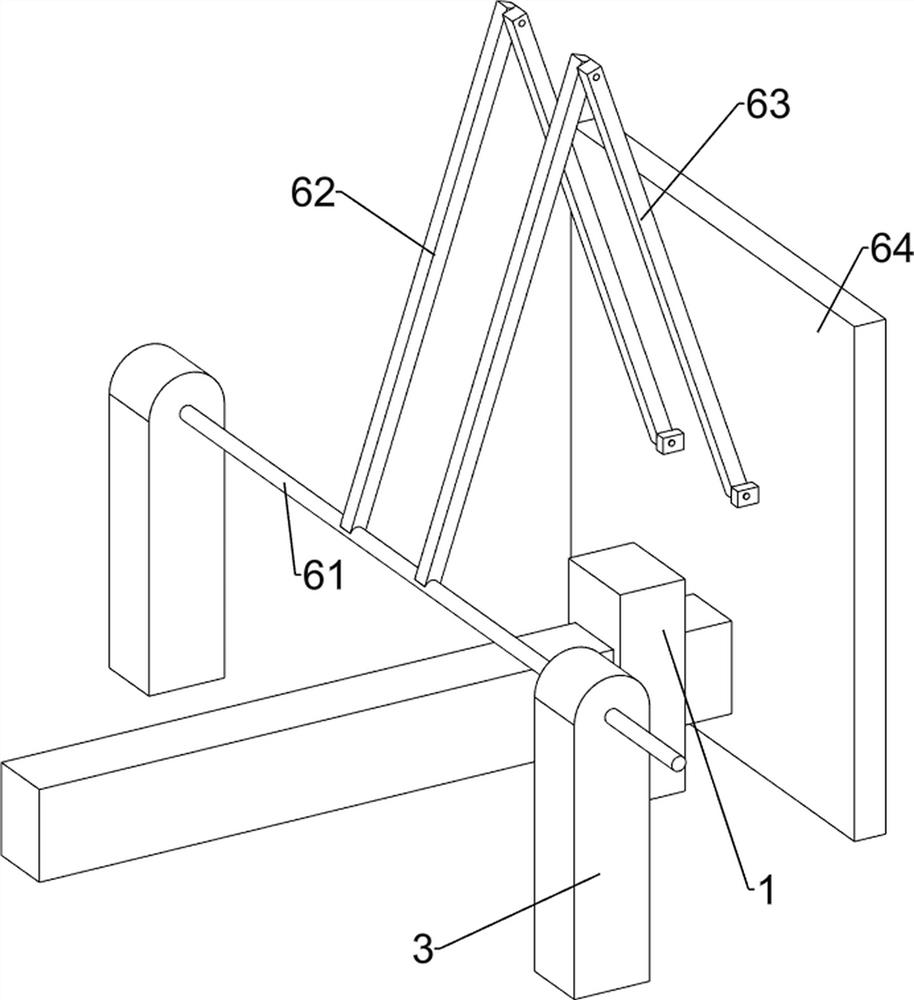

[0037] On the basis of Example 1, such as Figure 5 As shown, a pusher assembly 6 is also included, and the pusher assembly 6 includes a third rotating shaft 61, a first connecting rod 62, a second connecting rod 63 and a push plate 64, and the support rods 3 on both sides are rotatably connected with The third rotating shaft 61, the middle part of the third rotating shaft 61 is connected with the first connecting rod 62, the upper right side of the first connecting rod 62 is hingedly connected with the second connecting rod 63, and the right side of the second connecting rod 63 is rotationally connected with the push plate 64. The push plate 64 is located on the right left of the storage basket 41, and the push plate 64 is slidably connected with the bracket 1.

[0038] When the lotus root belt needs to be pushed to the right to collect after the cutting is completed, the third connecting rod 61 is manually rotated to drive the first connecting rod 62 to rotate, and the first...

Embodiment 3

[0040] On the basis of Example 2, such as Image 6 As shown, a transmission assembly 7 is also included. The transmission assembly 7 includes a fourth rotating shaft 71, a belt transmission group 72, a one-way gear 73 and a second rack 74. The upper part of the pole 2 is rotatably connected to the fourth rotating shaft 71. A belt transmission group 72 is connected between the four rotating shafts 71 and the third rotating shaft 61, a one-way gear 73 is connected to the rear side of the fourth rotating shaft 71, a second rack 74 is connected to the left side of the first rack 54, and the second rack 74 is connected to the left side of the second rack. 74 meshes with one-way gear 73.

[0041] When manually starting the cylinder 46 to move the telescopic rod upward, the upward movement of the first rack 54 drives the second rack 74 to move upward, and the upward movement of the second rack 74 drives the one-way gear 73 to rotate, and the one-way gear 73 rotates through the belt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com